Detergent as well as preparation method and application thereof

A technology of cleaning agent and fatty acid methyl ester, which is applied in the field of cleaning agent and its preparation and application. It can solve the problems of high corrosion, easy to form dirt, and incapable of equipment circulation, so as to improve the ability of shedding carbon deposits and prevent secondary contamination of dirt. Precipitation, increase the effect of osmotic function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A cleaning agent, calculated by weight percentage, its raw material composition and content are as follows:

[0032] Fatty acid methyl esters 95%

[0033] Polycarboxylate 2%

[0034] Polyoxyethylene ether 3%;

[0035] The fatty acid methyl ester is a long-chain fatty acid methyl ester;

[0036] The long-chain fatty acid methyl ester is lauryl fatty acid methyl ester, that is, the carbon chain of fatty acid is at 12;

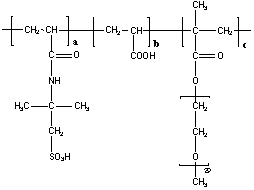

[0037] Described polycarboxylic acid molecular structural formula is as follows:

[0038]

[0039] Among them, a=1, b=10, c=0;

[0040] The polyoxyethylene ether is fatty alcohol polyoxyethylene (7) ether.

[0041] The preparation method of above-mentioned a kind of cleaning agent, step is as follows:

[0042] At room temperature, add polycarboxylic acid and fatty alcohol polyoxyethylene (7) ether into lauryl fatty acid methyl ester, stir evenly, and pack it in a can to obtain a cleaning agent.

Embodiment 2

[0044] A cleaning agent, calculated by weight percentage, its raw material composition and content are as follows:

[0045] Fatty acid methyl ester 99.6%

[0046] Polycarboxylate 0.2%

[0047] Polyoxyethylene ether 0.2%;

[0048] Described fatty acid methyl ester is epoxy fatty acid methyl ester;

[0049] The epoxy fatty acid methyl ester is epoxy octadecyl fatty acid methyl ester, that is, the carbon chain of the fatty acid is at 18;

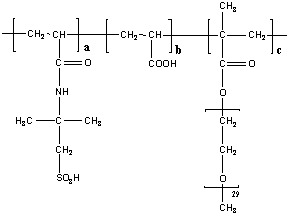

[0050] Described polycarboxylic acid molecular structural formula is as follows:

[0051]

[0052] Among them, a=1, b=8, c=1;

[0053] The polyoxyethylene ether is fatty alcohol polyoxyethylene (9) ether.

[0054] The preparation method of above-mentioned a kind of cleaning agent, step is as follows:

[0055] At room temperature, add polycarboxylic acid and fatty alcohol polyoxyethylene (9) ether into epoxy octadecyl fatty acid methyl ester, stir evenly, and pack it in a can to obtain a cleaning agent.

Embodiment 3

[0057] A cleaning agent, calculated by weight percentage, its raw material composition and content are as follows:

[0058] Fatty acid methyl esters 95%

[0059] Polycarboxylate 2%

[0060] Polyoxyethylene ether 3%;

[0061] The fatty acid methyl ester is formed by compounding epoxy fatty acid methyl ester and long-chain fatty acid methyl ester in a weight ratio of epoxy fatty acid methyl ester: long-chain fatty acid methyl ester in a ratio of 40:55;

[0062] The epoxy fatty acid methyl ester is epoxy pentacyl fatty acid methyl ester, that is, the carbon chain of the fatty acid is at 25;

[0063] The long-chain fatty acid methyl ester is hexadecyl fatty acid methyl ester, that is, the carbon chain of the fatty acid is at 16;

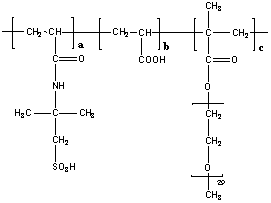

[0064] Described polycarboxylic acid molecular structural formula is as follows:

[0065]

[0066] Among them, a=2, b=5, c=1;

[0067] The polyoxyethylene ether is fatty alcohol polyoxyethylene (15) ether.

[0068] The preparation method of abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com