Corrosive liquid for 300M metallographic analysis and corrosion method

A technology of metallographic analysis and corrosion solution, which is applied in the field of aerospace and can solve problems such as inability to corrode grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Corrosive solution configuration

[0053] Use 15ml of analytically pure nitric acid with a concentration of 67%, add it to 80ml of distilled water, take 10ml of this solution and add it to 75ml of picric acid saturated aqueous solution to obtain component A of the corrosion solution; use 6ml of analytically pure hydrochloric acid with a concentration of 36%, add it to In 100ml of distilled water, take 6ml of the solution and add it to 100ml of picric acid saturated ethanol solution to obtain component B of the corrosion solution;

[0054] Mix evenly according to the following weight ratio:

[0055] 25g of corrosion solution component A; 70g of corrosion solution component B; 4g of diethyl ether, 2g of 2, 4, 6-trinitroquinone; 0.1g of dodecyltrimethylammonium chloride.

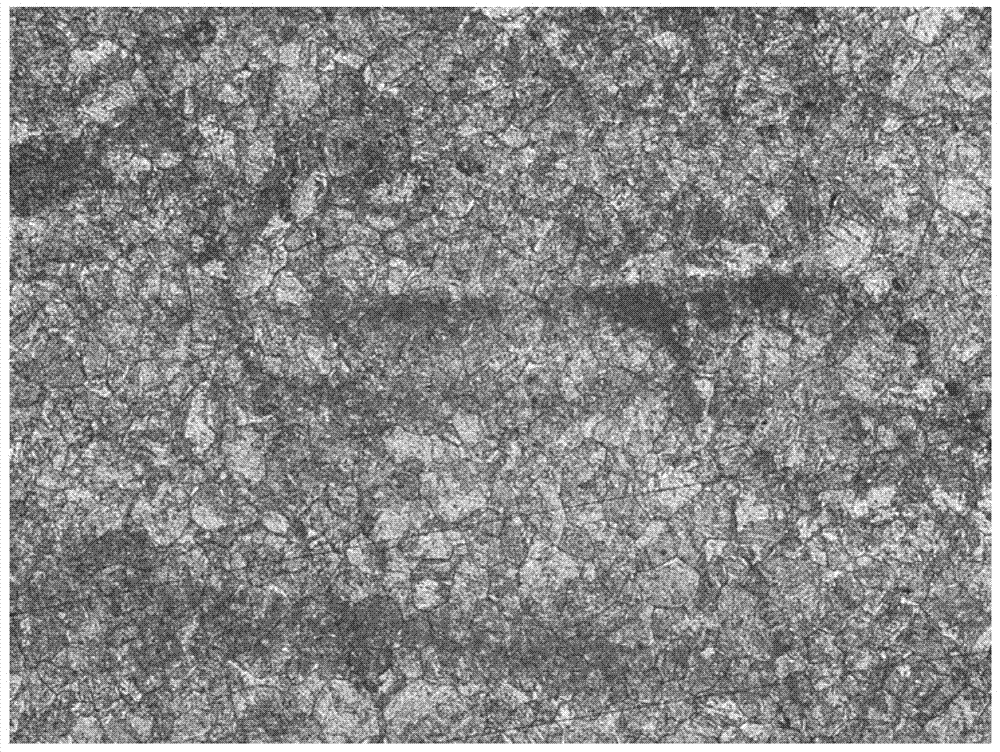

[0056] Then, the samples of 300M steel etc. were ground, polished, cleaned and dried according to the procedures of metallographic analysis, and then immersed in the corrosive solution at about 16°C, co...

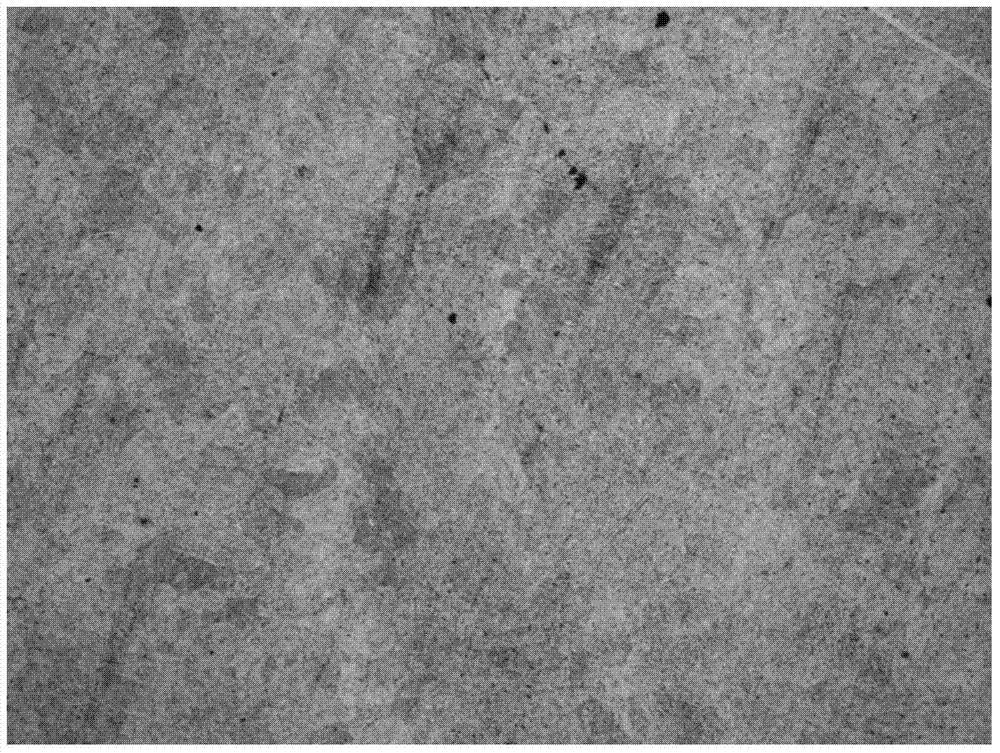

Embodiment 2~6

[0058] The method of configuring the etching solution and the etching process are similar to those in Example 1. See Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com