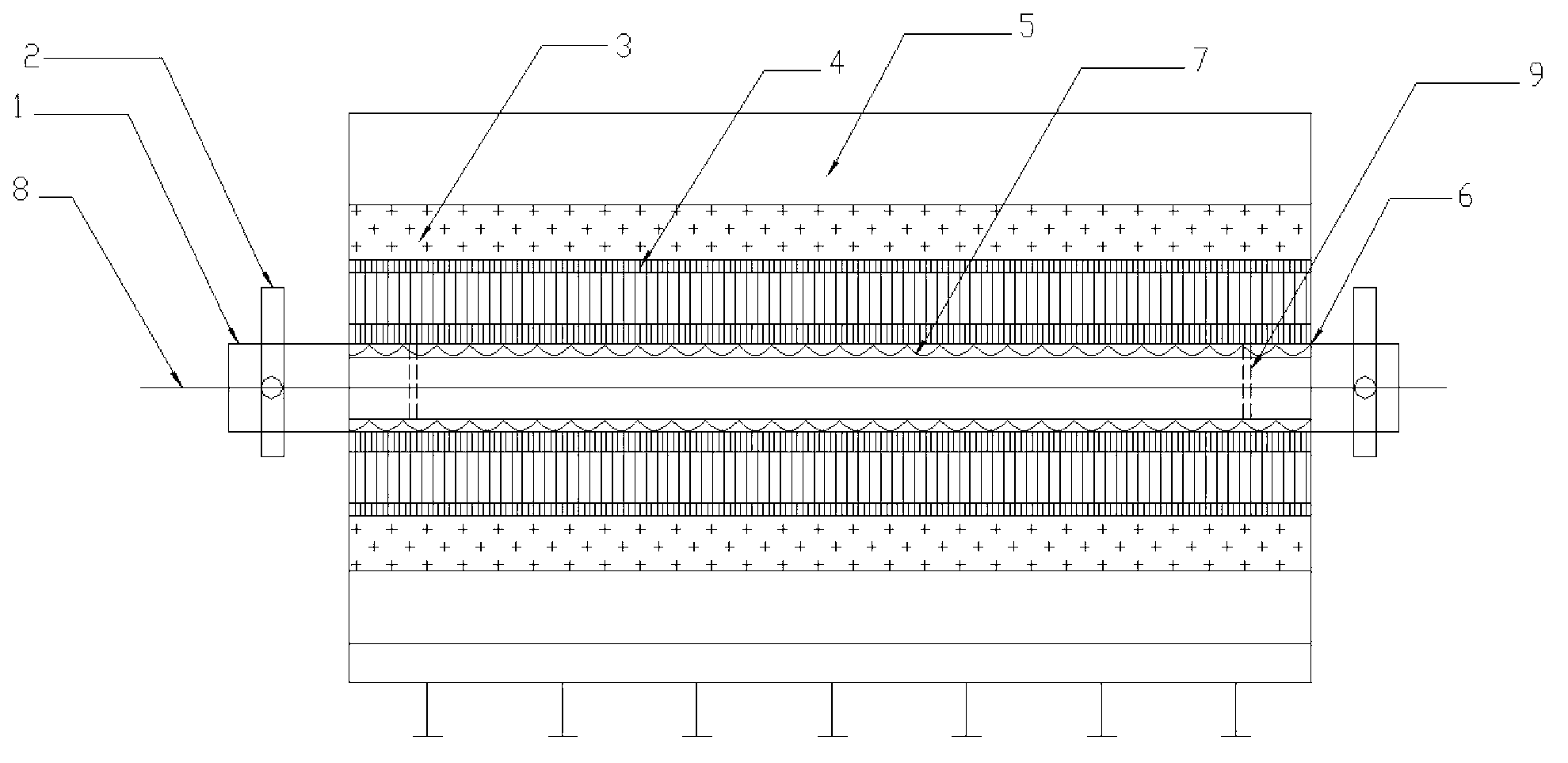

Polyimide fiber thermal drafting furnace and method

A polyimide fiber and thermal drawing technology, which is applied in the thermal drawing furnace of polyimide fiber and the field of thermal drawing of polyimide fiber, can solve the problem that the mechanical properties of polyimide fiber cannot meet the requirements of use. lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

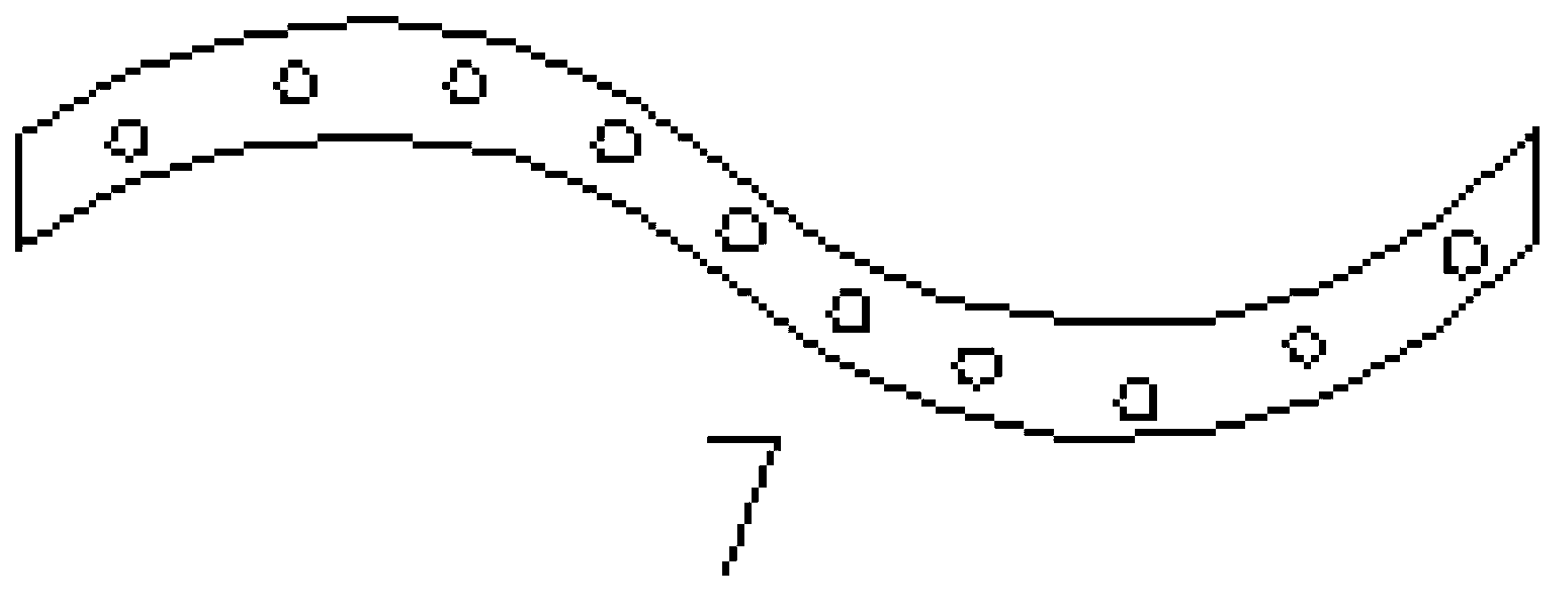

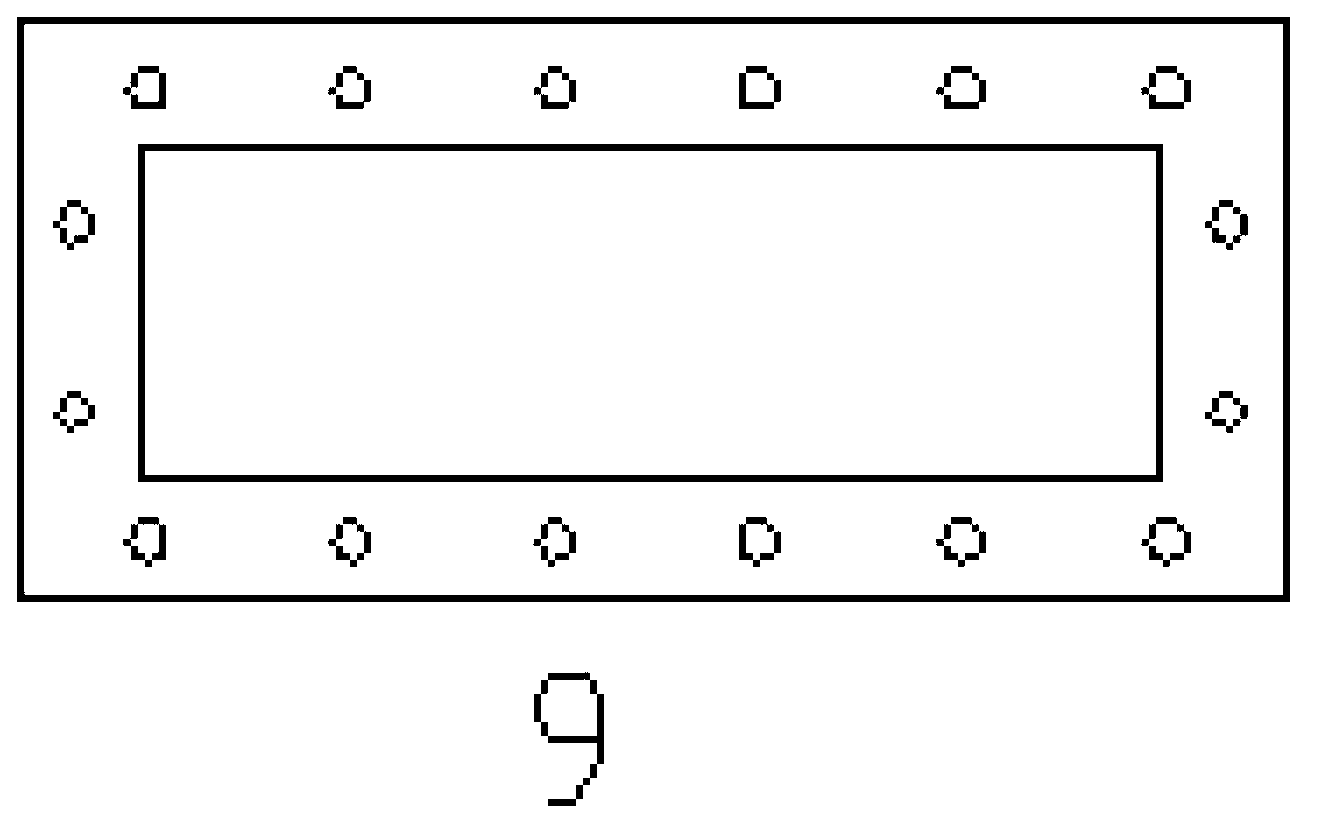

Method used

Image

Examples

Embodiment 1

[0095] The polyimide precursor to be treated is hot-drawn in the hot-drawing furnace provided by the present invention, and drawn 2.0 times at 350°C under a nitrogen atmosphere (the oxygen content in the gas in the furnace is below 10ppm) to obtain polyimide Amine finished fibers.

[0096] The present invention carries out performance test on the obtained polyimide finished fiber, and the result shows that the breaking strength of the polyimide fiber obtained in this embodiment is 1.81GPa, the modulus is 15.65GPa, and the breaking elongation is 12.6%.

Embodiment 2

[0098] The polyimide fibrils to be treated are thermally drawn in the hot drawing furnace provided by the present invention, and stretched 2.8 times at 520°C under a nitrogen environment (the oxygen content in the gas in the furnace is below 10ppm), and the polyimide fibrils are obtained. Amine finished fibers.

Embodiment 3

[0104] The polyimide fibrils to be treated are thermally drawn in the hot drawing furnace provided by the invention, and drawn 2.5 times at 510°C in a nitrogen environment (the oxygen content in the gas in the furnace is below 10ppm), to obtain polyimide Imine finished fibers.

[0105] The present invention carries out the performance test of the finished fiber obtained, and the result shows that the breaking strength of the finished fiber obtained in this embodiment is 1.81GPa, the modulus is 18.95GPa, and the elongation at break is 9.32%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com