The method of making ice and storing ice on the ice surface by using cold wind in winter

A technology for cold air and ice storage, which is applied in ice making, application, and ice making, etc., can solve the problems of high climatic conditions, low ice making efficiency, and high energy consumption, so as to reduce manpower and energy consumption and improve ice making efficiency. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing

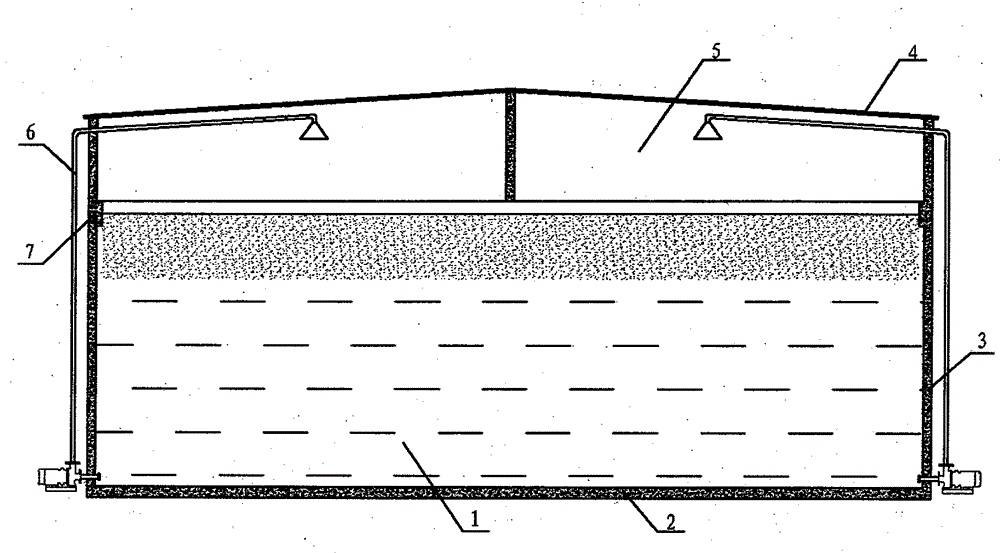

[0015] Such as figure 1 As shown, build a rectangular deep underground or semi-subterranean ice-making ice storage tank (1), the main wind direction of the long side facing the winter wind, the bottom of the pool (2) and the pool wall (3) are with insulation layer Concrete structure, the roof of the pool (4) is a large-span steel structure roof with a heat insulation layer, the ventilation belt (5) is reserved between the surrounding pool wall and the roof, and the outside of the pool wall is composed of water pumps, water pipes and ice storage The sprinklers on the pool top form a controllable sprinkler system (6), and the top water pipes are connected to the sprinklers in an inclined shape. In winter, the water stored in the ice-making ice storage tank reaches the predetermined water level, and the cold wind blows into the pool from the ventilation belt, and the water sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com