System and method for coplanarity measurement of ic pins with multi-stage reflection and grating imaging

A grating imaging and measurement system technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of bulky, low detection accuracy, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

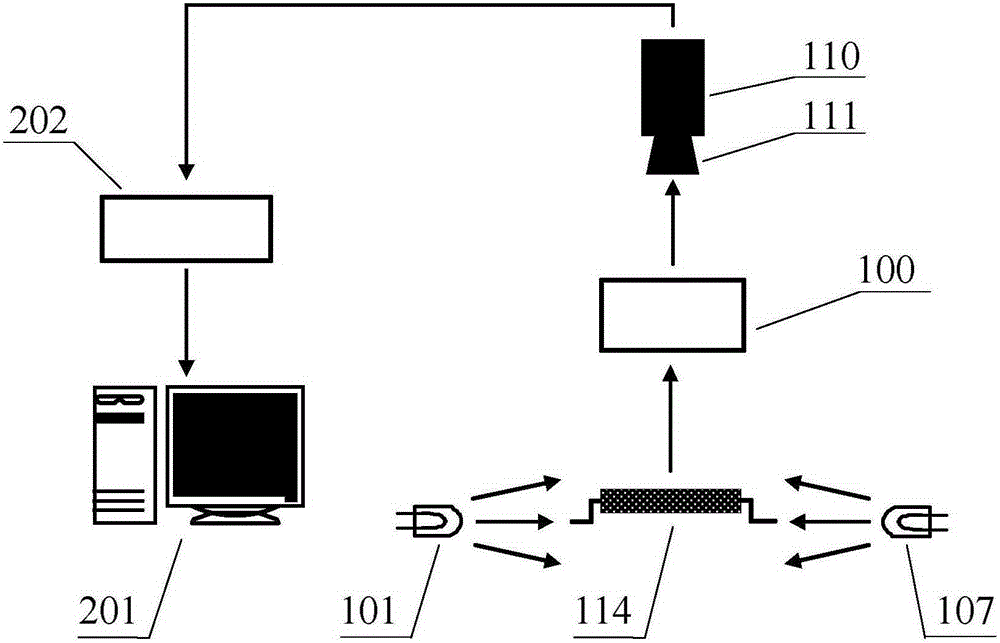

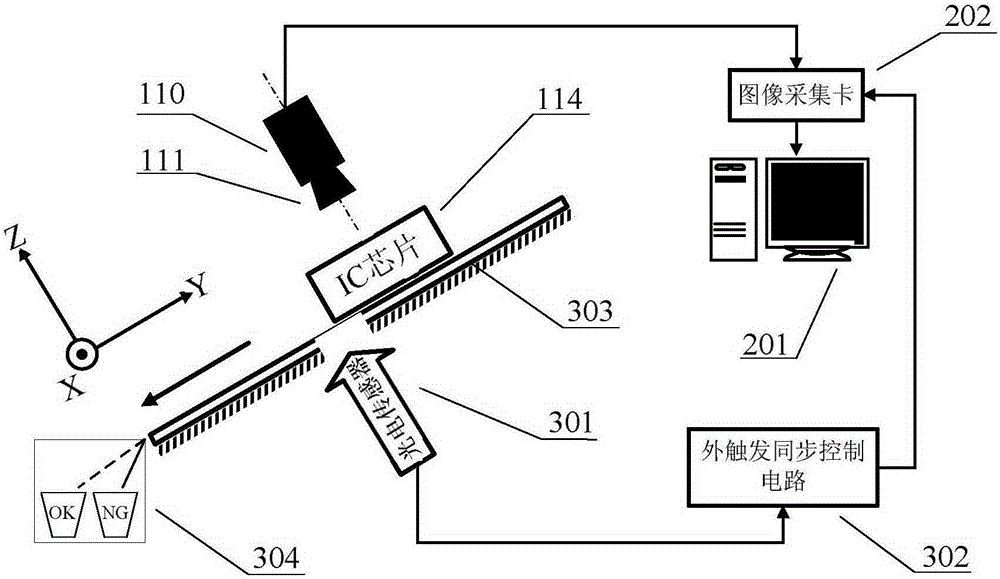

[0060] like figure 2 As shown, the main frame of the system of the present invention includes: an IC chip pin imaging optical path system 100 composed of multi-reflectors, gratings and isosceles prisms, an IC chip self-weight oblique sliding feed mechanism 303, an image acquisition card 202, a CCD camera 110 An imaging unit composed of a lens 111 , a PC-based intelligent visual measurement system 201 , an external trigger synchronous control circuit 302 , and a superior or inferior product classification device 304 .

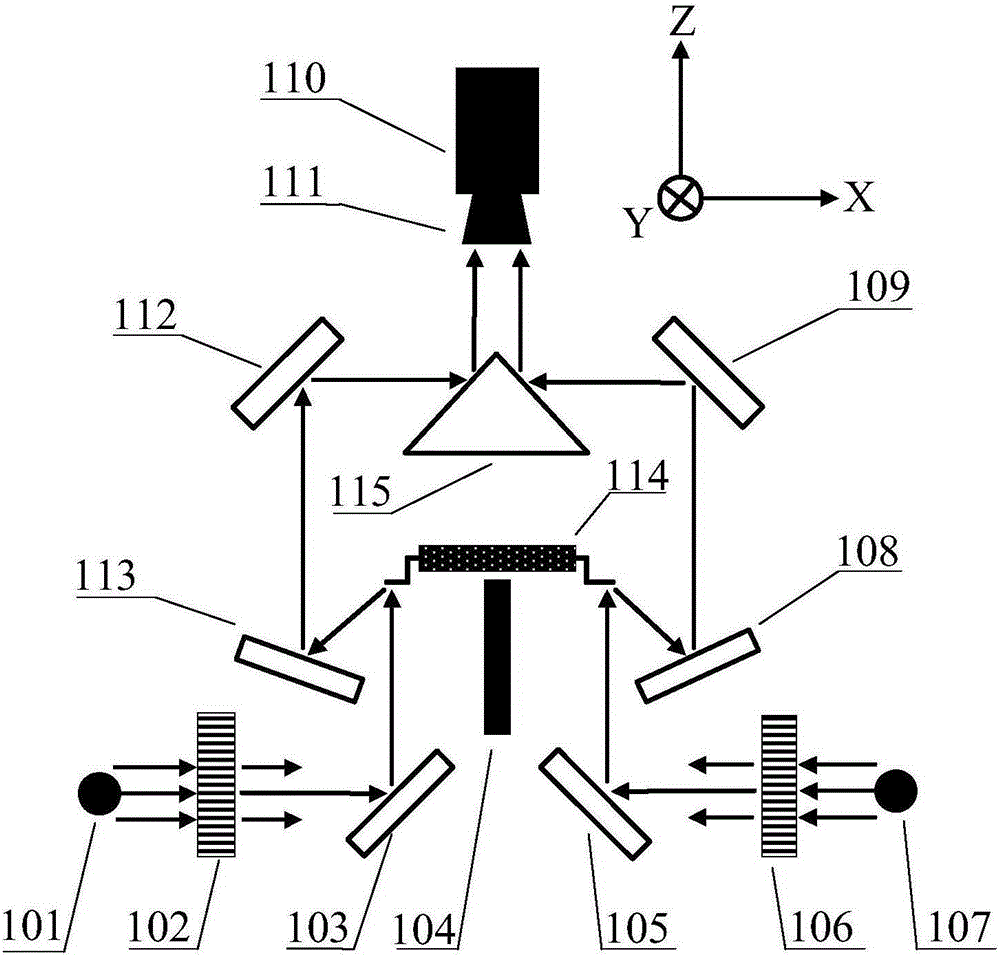

[0061] like figure 1As shown, it is the special optical path system proposed by the present invention: IC chip pin imaging optical path system 100, the left optical path of the IC chip pin imaging optical path system 100 includes: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com