Control system architecture of modular multilevel converter

A modular multi-level, control system technology, applied in general control systems, control/regulation systems, simulators, etc., can solve problems such as increasing system complexity, method complexity, and reducing real-time performance, reducing the number of optical fibers used , The effect of less transmission bits and high real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

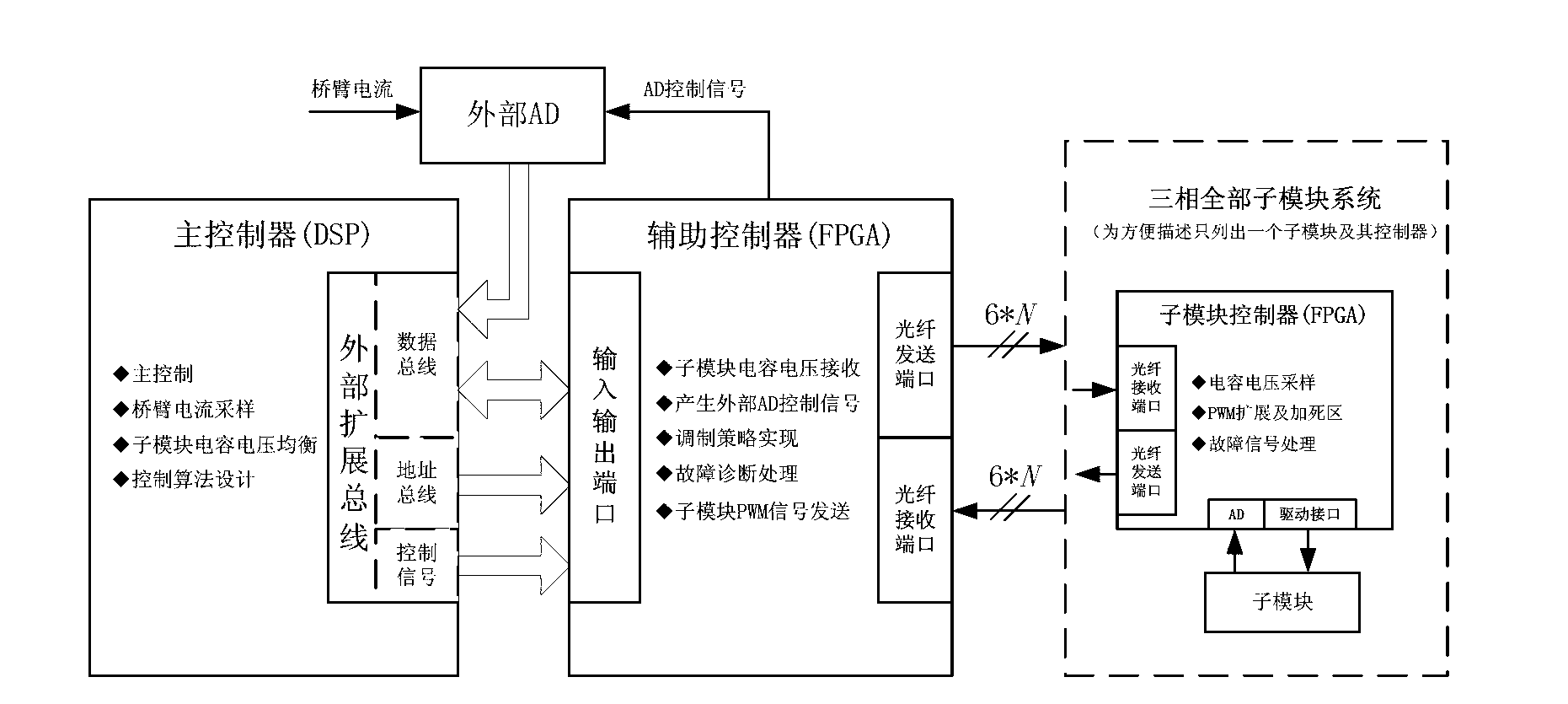

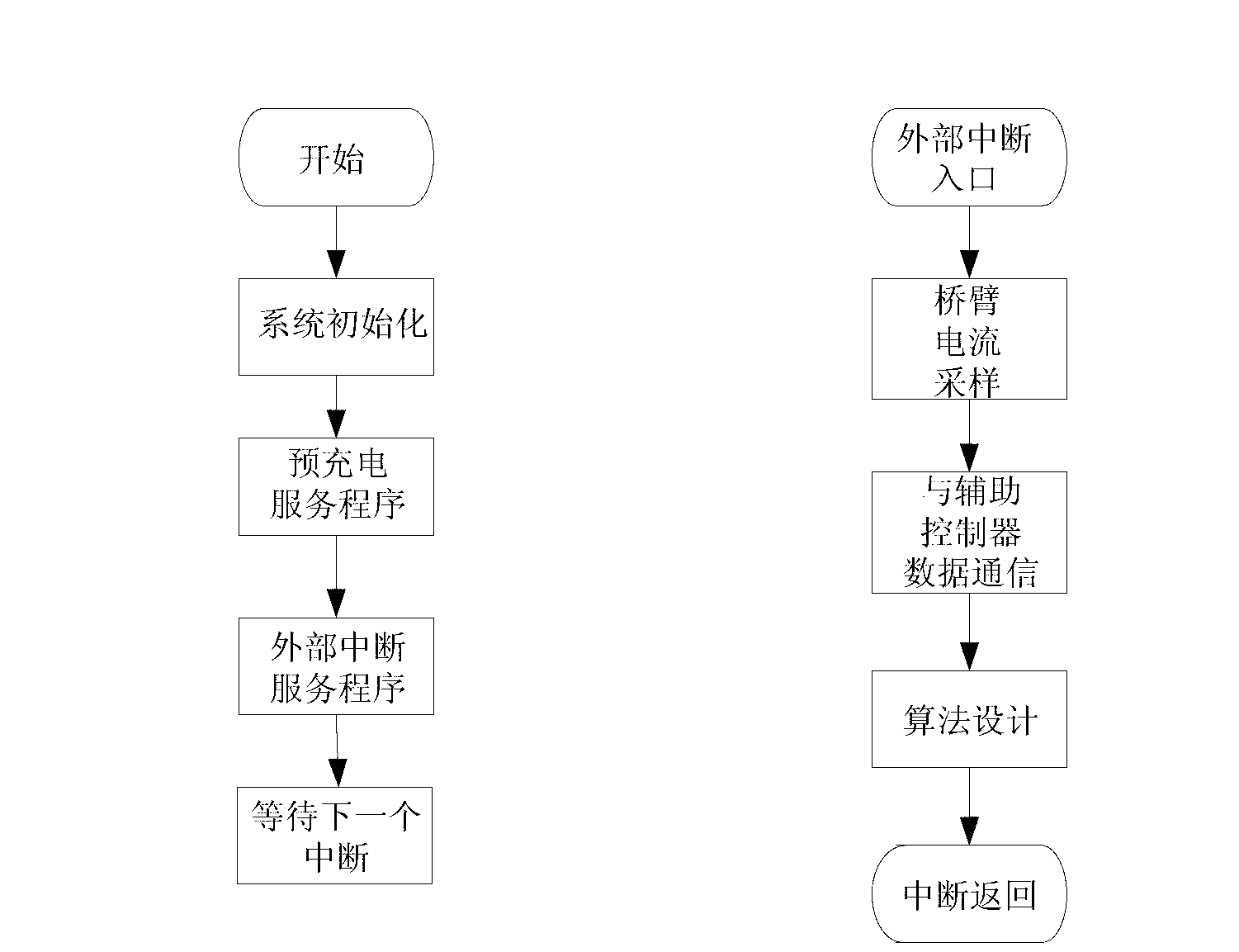

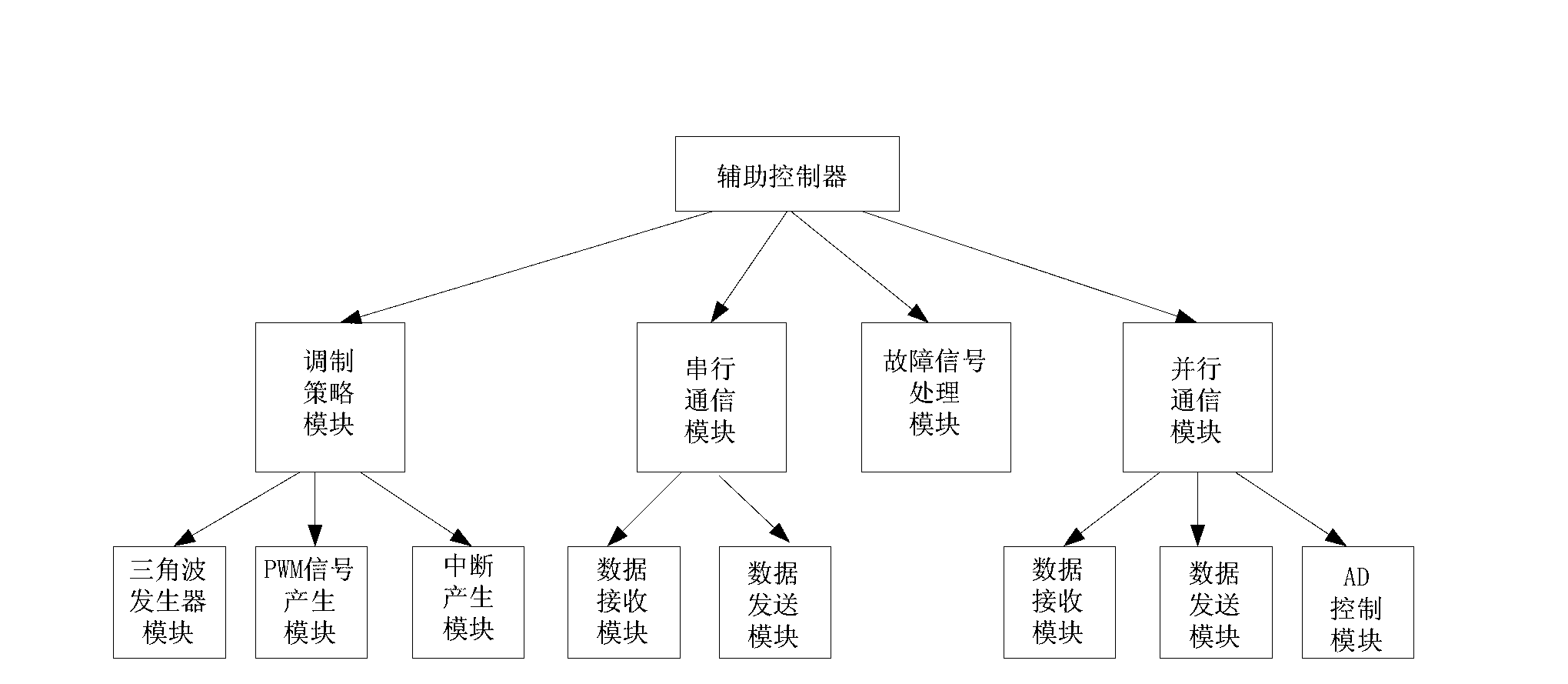

[0020] figure 1 It is a block diagram of the control system architecture of a modular multilevel converter. The control architecture is composed of a main controller, an auxiliary controller, a three-level control architecture of a module controller, and an externally extended AD. The main controller is composed of a DSP, and the auxiliary controller It is composed of FPGA, and the module controller is composed of FPGA. The main controller is connected with the auxiliary controller through XINTF of DSP, and uses parallel communication to exchange data; the auxiliary controller is connected to the module controller through 2 optical fibers, and uses serial communication to exchange data. The main controller DSP is used for main control, bridge arm current sampling, sub-module voltage equalization and algorithm design, and the auxiliary controller FPGA is used for sub-modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com