High-density integrated micro-nano photoelectron chip radiator based on thermoelectric cooler

A technology of thermoelectric coolers and electronic chips, which is applied in the direction of electric solid devices, thermoelectric devices and circuits that only use the Peltier or Seebeck effect, and can solve the problems of heat dissipation, energy consumption and large noise of heat dissipation devices, and achieve high safety and low The effect of noise and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

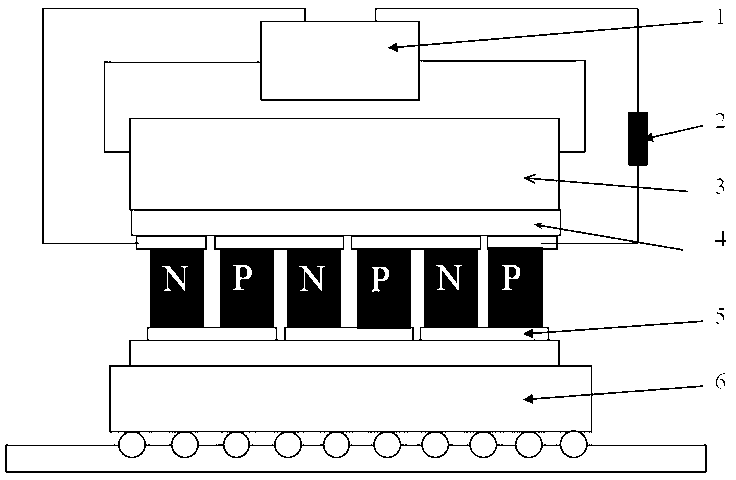

[0011] figure 1 It is a cooling device based on a thermoelectric cooler of the present invention, which includes a conventional commercially available miniature Stirling generator 3, a thermoelectric cooler, and a power module 1, wherein the thermoelectric cooler includes a ceramic substrate 4 and a heat conducting sheet 5, P-type and N-type bismuth telluride materials. The thermoelectric cooler is installed on the top of the chip 6 integrated assembly, and one end is in contact with the upper surface of the chip 6 integrated assembly. The thermal cavity of the Stirling generator 3 is connected and installed on the refrigerator, so that the thermal cavity of the generator is in contact with the other end of the refrigerator. The Stirling generator 3 is connected in parallel with the power module 1, and the power module 1 is connected in parallel with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com