Efficient enrichment and separation equipment for ultralow-concentration gas

An ultra-low concentration, separation equipment technology, applied in the field of resources and energy, can solve the problems of polluting the environment and wasting energy, and achieve the effects of reducing emissions, improving adsorption efficiency, and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

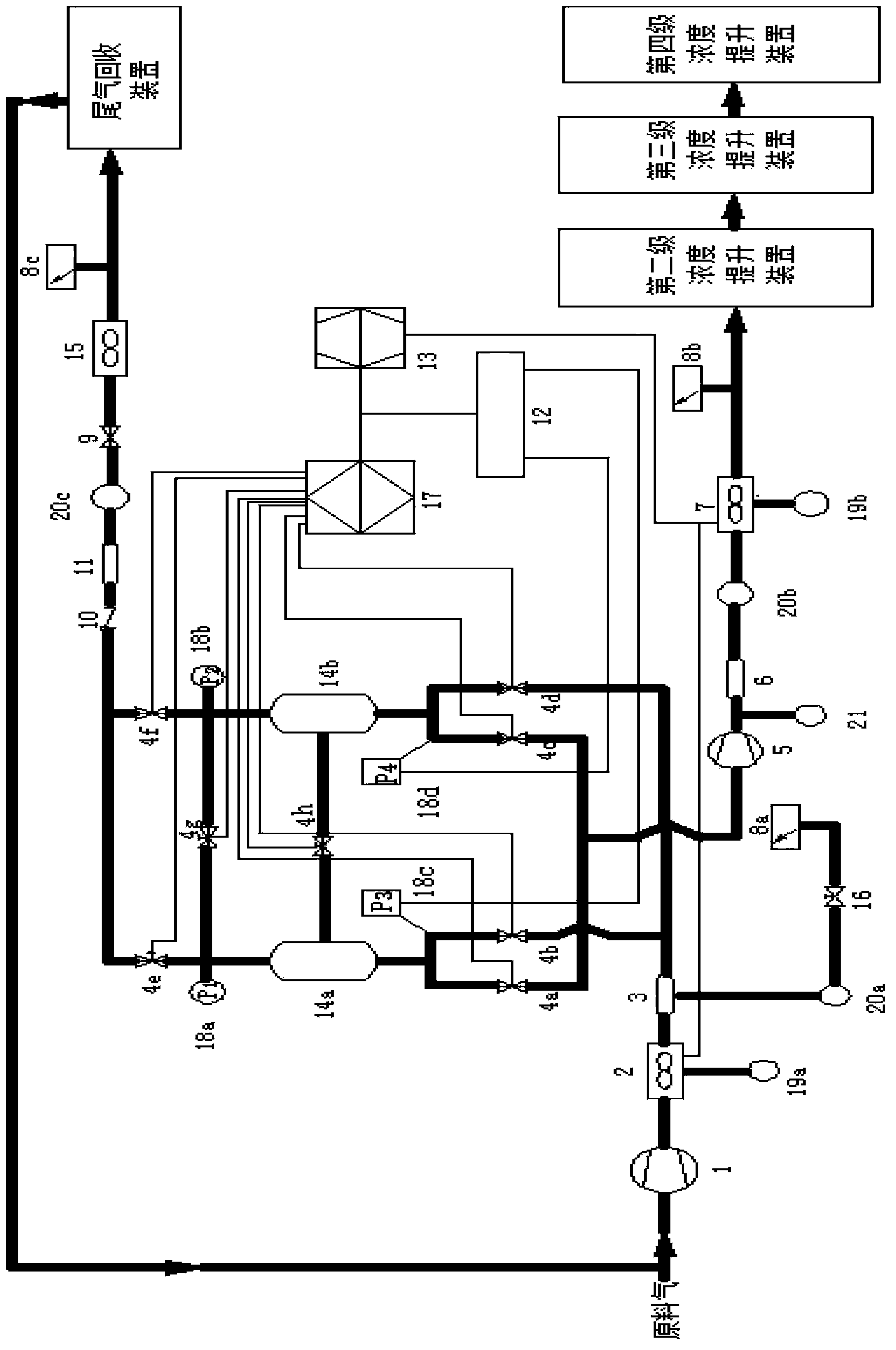

Method used

Image

Examples

specific Embodiment 1

[0044] Specific embodiments 1. Adsorption at normal pressure and 25°C, vacuum analysis at 20kPa, gas flow rate of 500sccm, adsorption in the adsorption tower, the ratio of the diameter of the analysis pipe to the total length is 1:4, and the use of 1000m 2 Under the condition that the modified activated carbon per g is used as the adsorbent, the methane concentration of the raw material gas is 0.10%, the methane concentration of the first-stage imported raw material gas is 0.10%, and the concentration of the desorption gas flowing out of the first-stage desorption tower is 2.88%. The concentration of the product gas flowing out of the adsorption tower is 0.02%; the methane concentration of the second-stage imported raw material gas is 2.88%, the concentration of the analytical gas flowing out of the second-stage desorption tower is 17.92%, and the concentration of the product gas flowing out of the second-stage adsorption tower is 0.21% , the second-stage product gas enters th...

specific Embodiment 2

[0045] Specific embodiment 2. Adsorption at normal pressure and 25°C, vacuum analysis at 20kPa, gas flow rate of 500sccm, adsorption in the adsorption tower, the ratio of the diameter of the analysis pipe to the total length is 1:9, and the use of 1000m 2 Under the condition that the modified activated carbon per gram is used as the adsorbent, the methane concentration of the raw material gas is 0.10%, the methane concentration of the first-stage imported raw material gas is 0.10%, and the concentration of the desorption gas flowing out of the first-stage desorption tower is 3.12%. The concentration of the product gas flowing out of the adsorption tower is 0.01%; the methane concentration of the second stage imported raw material gas is 3.12%, the concentration of the analytical gas flowing out of the second stage desorption tower is 19.26%, and the concentration of the product gas flowing out of the second stage adsorption tower is 0.15% , the second-stage product gas enters ...

specific Embodiment 3

[0046] Specific embodiment 3. Adsorption at normal pressure and 25°C, vacuum analysis at a vacuum pressure of 20kPa, gas flow rate of 500sccm, adsorption in the adsorption tower, the ratio of the diameter of the analysis pipe to the total length is 1:12, and the use of 1000m 2 Under the condition that the modified activated carbon per g is used as the adsorbent, the methane concentration of the raw material gas is 0.10%, the methane concentration of the first-stage imported raw material gas is 0.10%, and the concentration of the desorbed gas flowing out of the first-stage desorption tower is 3.02%. The concentration of the product gas flowing out of the adsorption tower is 0.02%; the methane concentration of the second stage imported raw material gas is 3.02%, the concentration of the analytical gas flowing out of the second stage desorption tower is 18.63%, and the concentration of the product gas flowing out of the second stage adsorption tower is 0.19% , the second-stage pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com