Modified adsorption resin and preparation method thereof

An adsorption resin and modification technology, applied in the field of preparation of polymer separation materials, can solve the problems of poor adsorption performance, poor hydrophilicity, insufficient selectivity, etc., and achieve the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

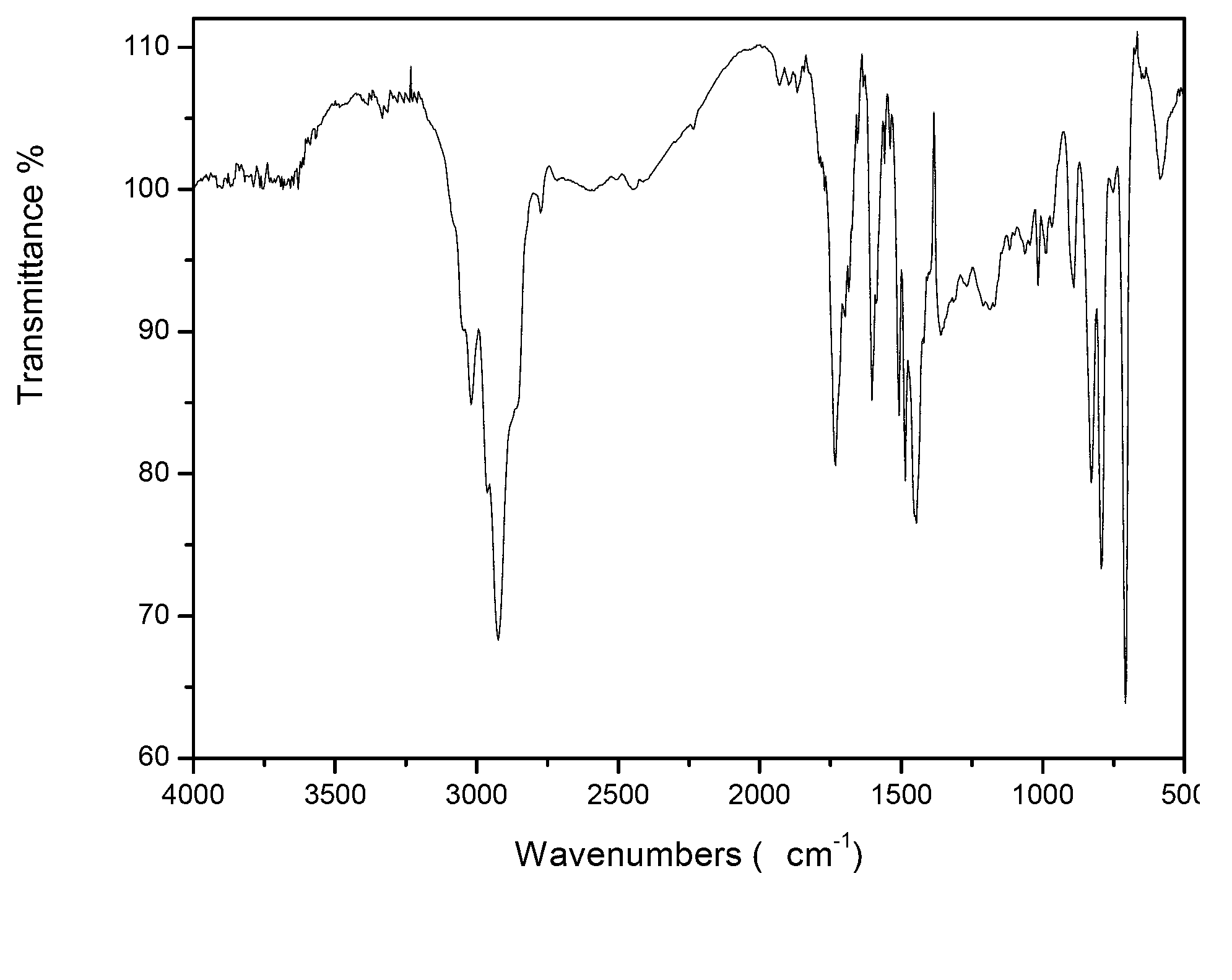

Image

Examples

Embodiment 1

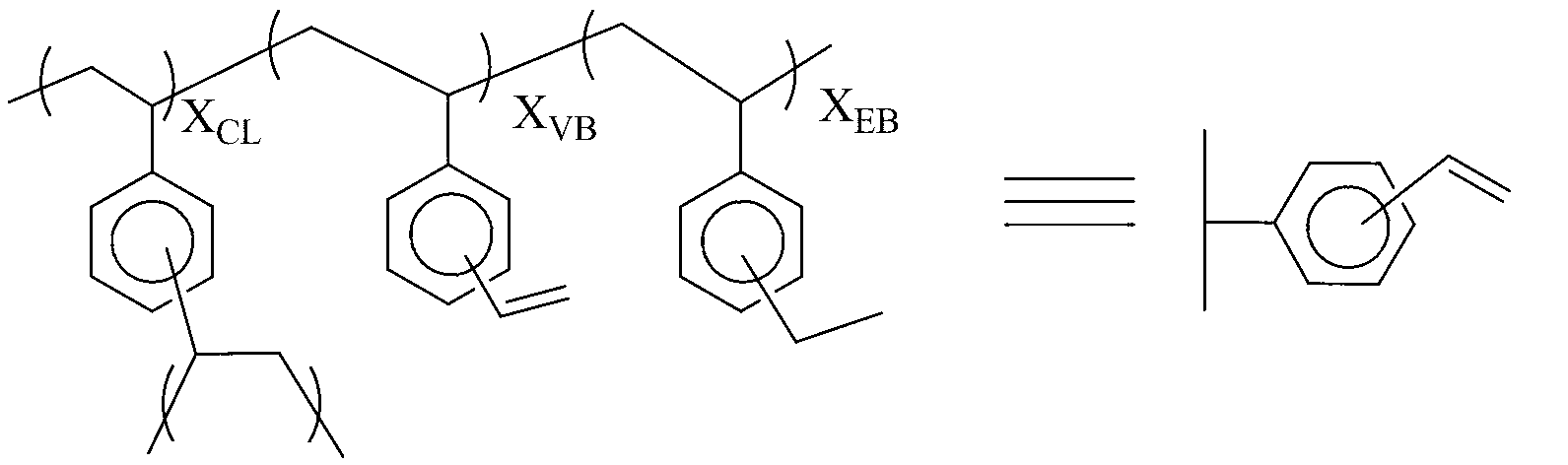

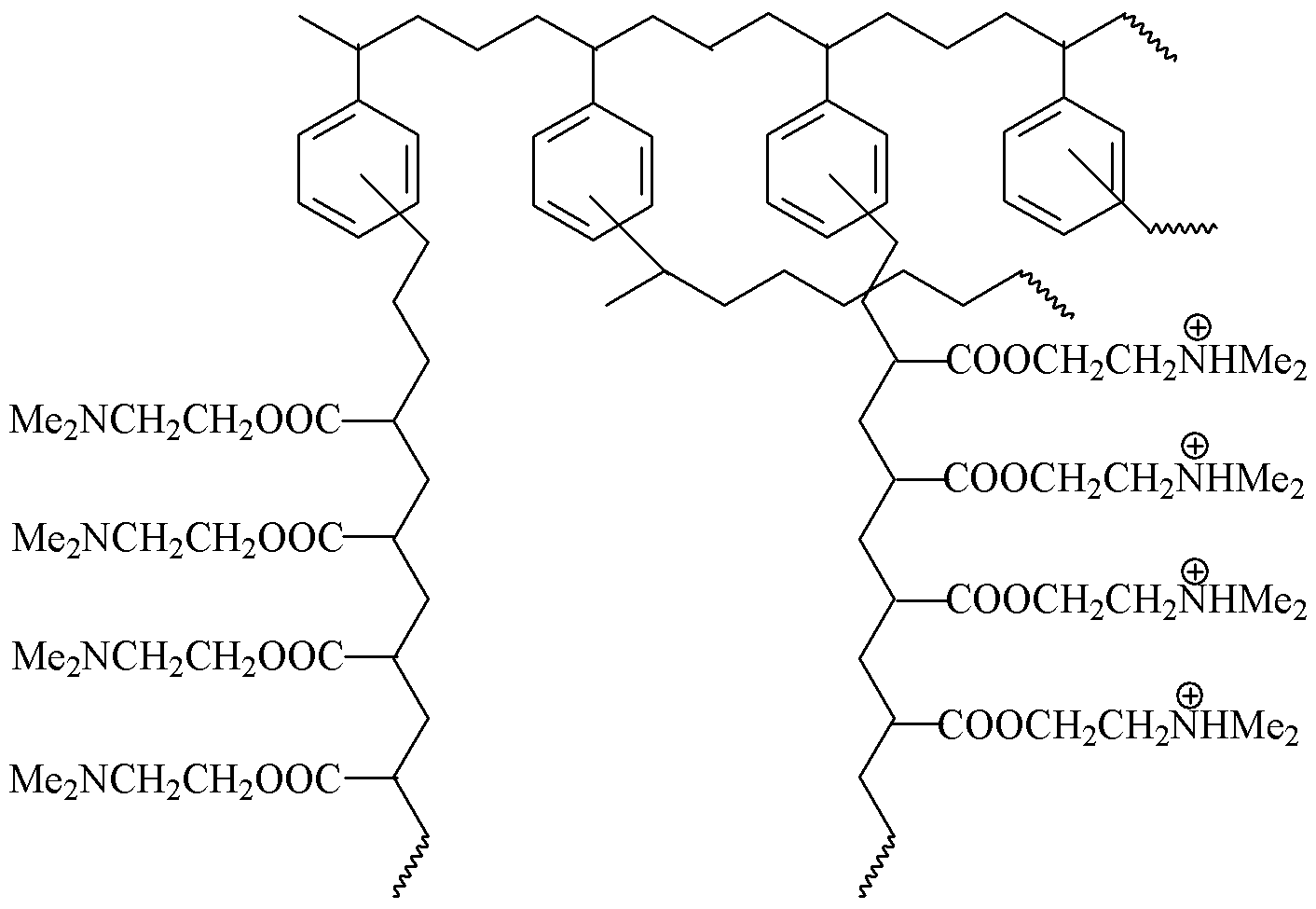

[0033] A modified adsorption resin in which a polar group and a protonatable tertiary amine group coexist and a preparation method thereof, comprising the following two steps:

[0034] step 1:

[0035] Add 800 g of deionized water and 8.0 g of gelatin to a 2000 mL three-neck flask equipped with a stirrer, reflux condenser, and thermometer, soak overnight, heat the water bath to 45°C the next day, and prepare the pre-prepared oil phase (single Divinylbenzene 100g DVB content of 55%, mixed with 200ml porogen toluene and initiator BPO 1.0g), adjust the stirring speed to disperse the organic phase into oil droplets with appropriate particle size Slowly raise the temperature to 77-79°C for 2 hours, then raise the temperature to 82-85°C for 3 hours, then raise the temperature to 90-92°C for 6 hours, then stop the reaction. Filter out the resin with a gauze bag while it is hot, wash the resin with a large amount of hot water until the washing water is clear, wash with acetone, extra...

Embodiment 2

[0039] By the same method as in Example 1, except that the monomeric industrial divinylbenzene DVB content is 70% (the ingredients are 40 parts of 55% divinylbenzene and 60 parts of 80% divinylbenzene), and the reaction process is the same as in Example 1.

[0040] Elemental analysis and determination can be calculated, the grafting rate of MDAEMA is 14.3%, the alkali exchange capacity is 0.82mmol / g, and the BET specific surface area is 680m 2 / g.

Embodiment 3

[0042] According to the same method of embodiment 1, only monomer industrial divinylbenzene DVB content is 80%, and the reaction process is the same as embodiment 1.

[0043] Elemental analysis and determination can be calculated, the grafting rate of MDAEMA is 19.5%, the alkali exchange capacity is 1.16mmol / g, and the BET specific surface area is 760m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com