Intelligent inner circle slicer

An inner circle slicing and intelligent technology, which is applied in shearing devices, metal processing machinery parts, maintenance and safety accessories, etc. The effect of splashing, reducing the incidence of fire, improving the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

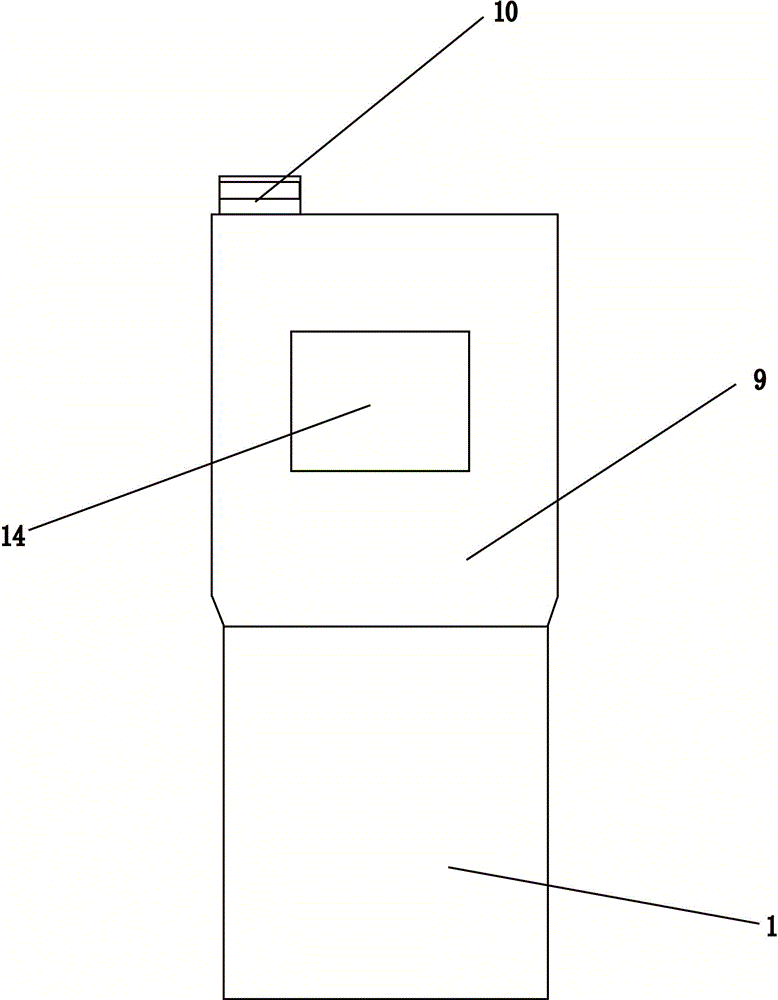

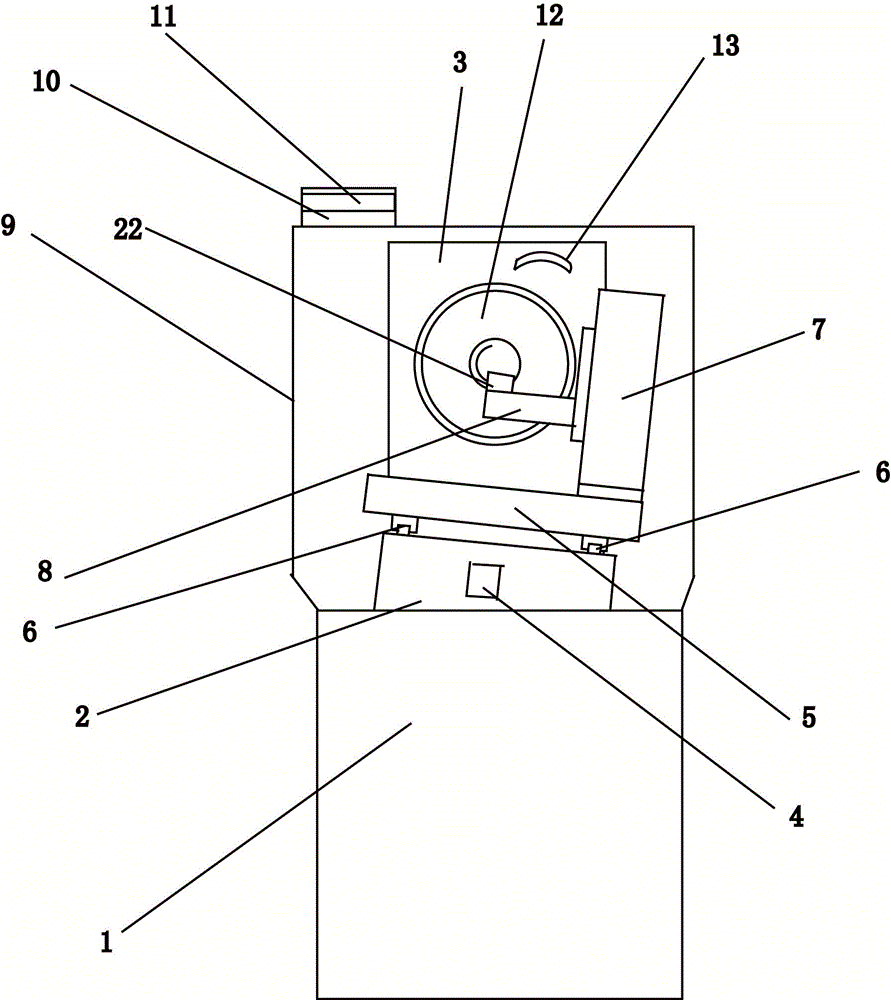

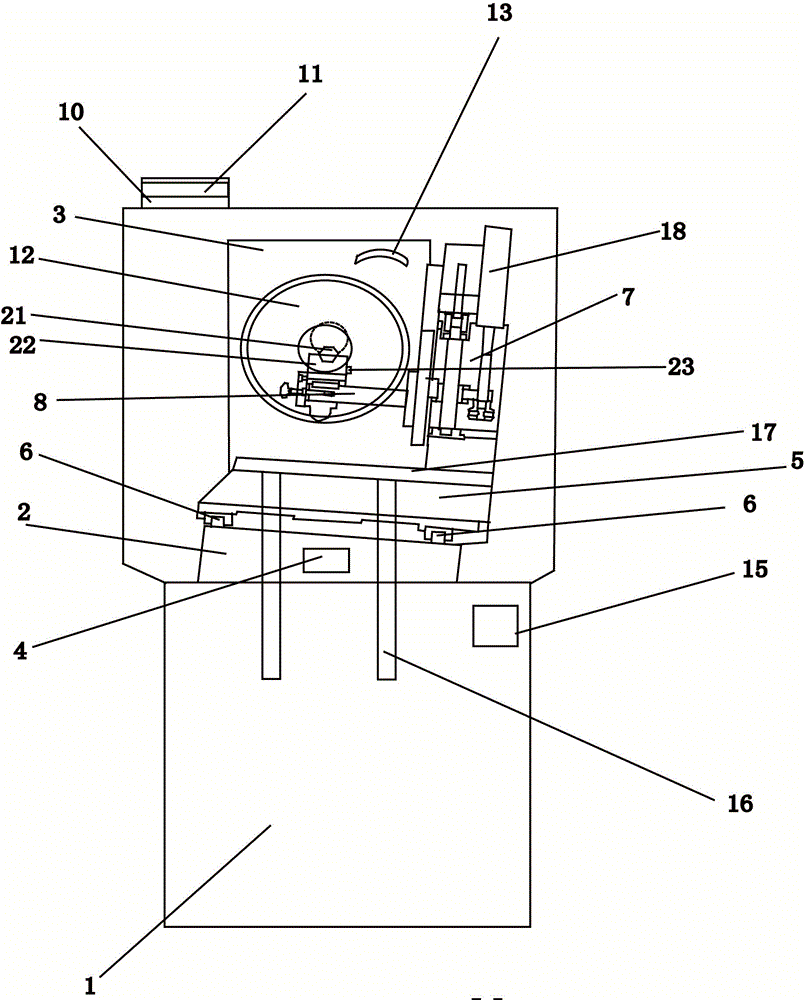

[0020] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 Shown: an intelligent internal circle slicer, including a control chip 15, a main cabinet 1, and a cutting table 3. The main body cabinet 1 is provided with a protective cover 9, and the top of the protective cover 9 has a smoke exhaust hole 10, and a smoke exhaust fan 11 is arranged in the smoke exhaust hole 10. The front of the protective cover 9 is provided with an openable and closable feeding window 14 . The main cabinet 1 is provided with a pedestal 2, and the pedestal 2 is horizontally inclined to the main cabinet 1, and the angle between the pedestal 2 and the main cabinet 1 is 5.2 degrees. A motor 4 is provided in the pedestal 2, and the pedestal 2 is provided with a feeding platform 5, and a slide rail 6 is arranged between the feeding pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com