Vacuum diffusion bonding method for TC18 titanium alloys

A TC18, vacuum diffusion technology, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problems of material performance deterioration, high technical difficulty, coarse structure, etc., and achieve excellent mechanical properties, high connection quality, and weakened The effect of the interface influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

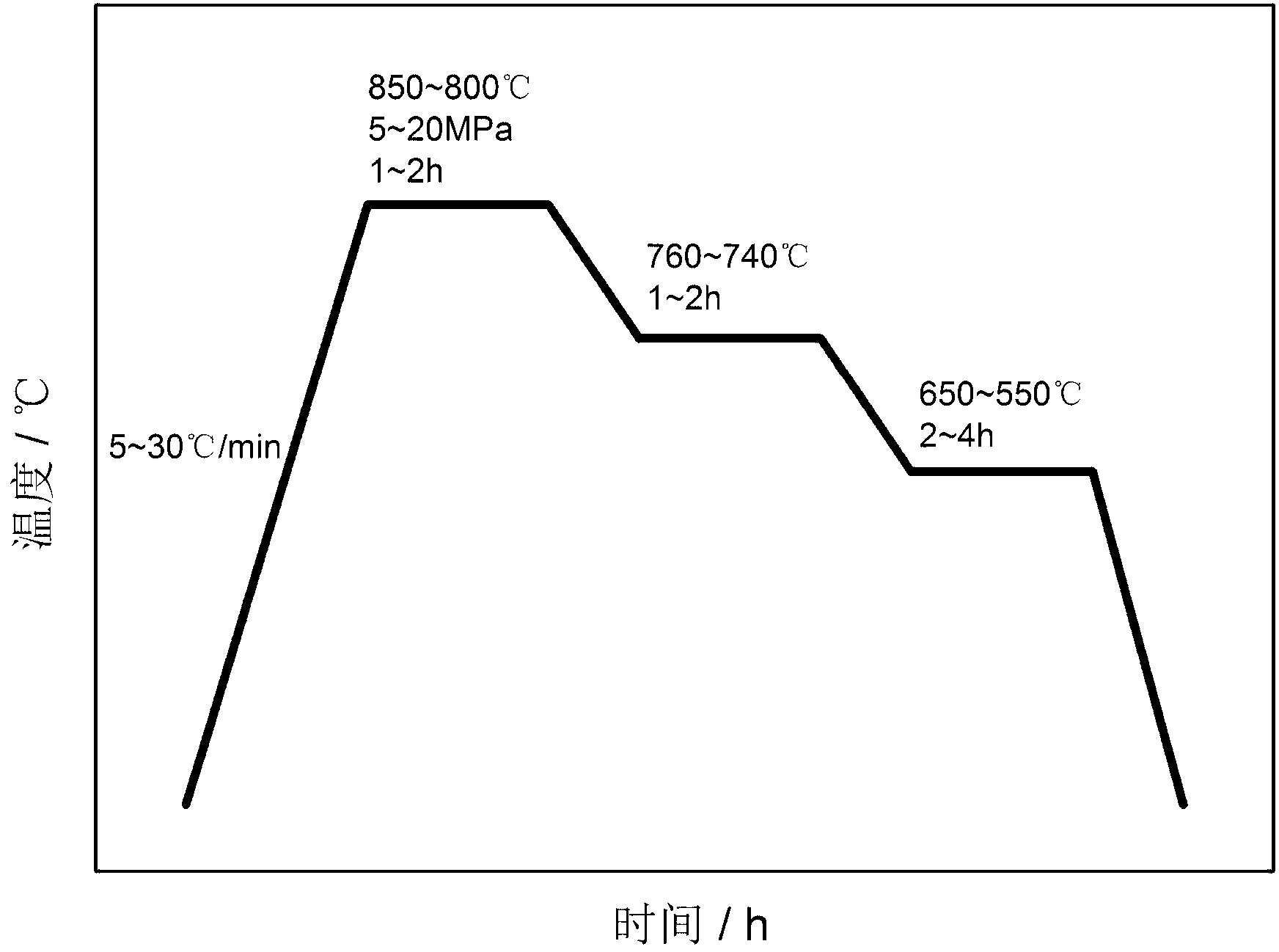

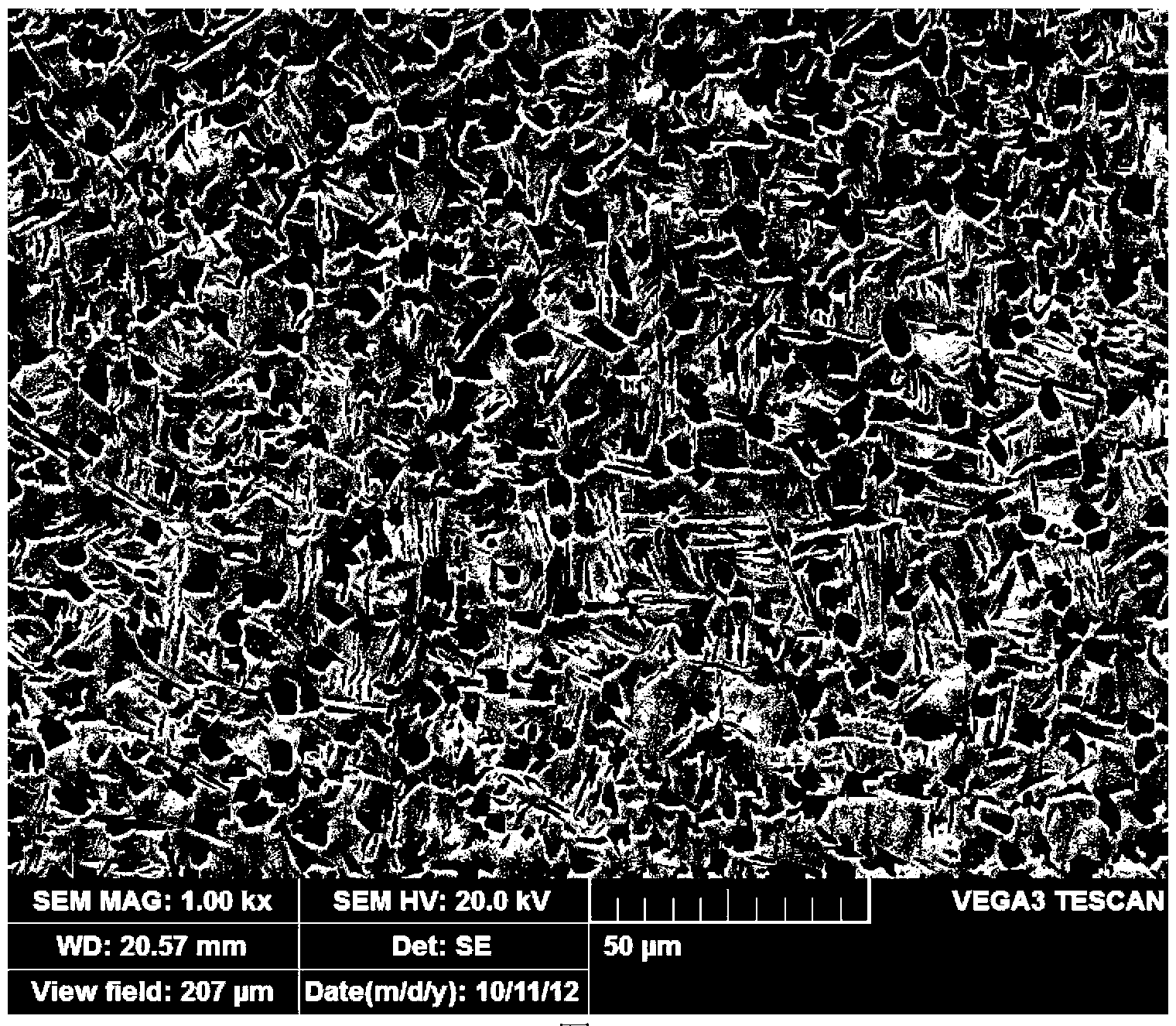

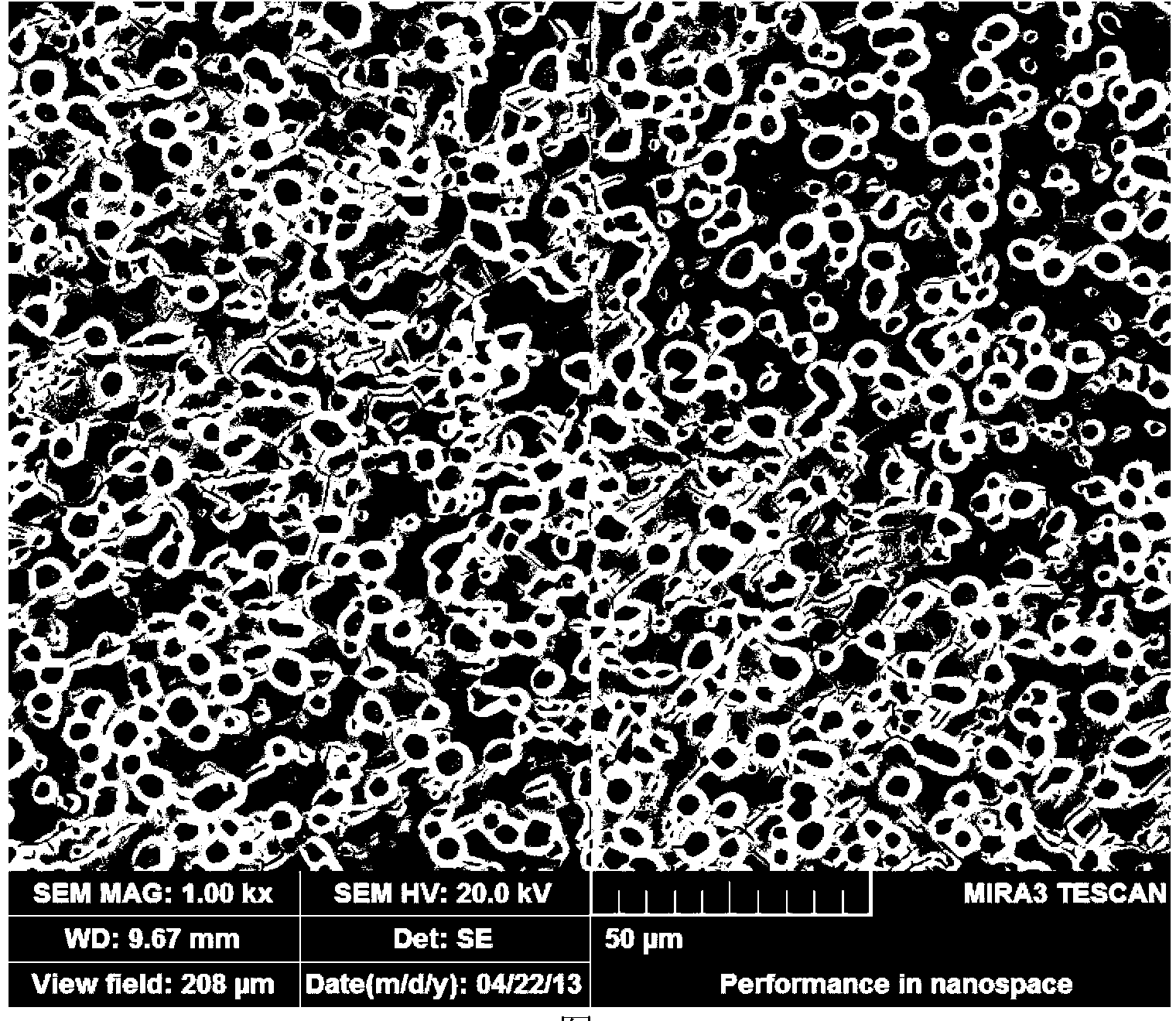

[0023] This embodiment is a TC18 titanium alloy vacuum diffusion bonding method that can control the microstructure. In this embodiment, the diffusion bonding method proposed in this patent is used to connect the cylindrical bottom surfaces of two TC18 titanium alloy forged specimens with a size of Φ12×3. While ensuring a good connection effect, the α phase (including primary, Secondary α-phase) diffusely distributed microstructure, so that the connector has a good comprehensive mechanical performance matching. In order to avoid the influence of material heat treatment on the test results of this method, the calcined TC18 titanium alloy was used for the test.

[0024] The specific process is:

[0025] Step 1: Treatment of the surface of the sample to be connected. Sequentially use 240#, 400#, 600#, 800#, 1000#, 1500# and 2000# SiC water sandpaper to polish the surface of each sample to eliminate obvious scratches on the surface to be connected and then use 1.5#, 0.5# diamond poli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com