UV makeup method of holographic dedicated plate

A special edition and holographic technology, which is applied in the imposition field of laser holographic special editions, can solve the problems of incomplete transfer of holographic information, affect the anti-counterfeiting performance of the printing effect, and difficulty in consistent quality of special edition patterns, so as to avoid obvious and convenient imposition seams Effects of operation, cost avoidance and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

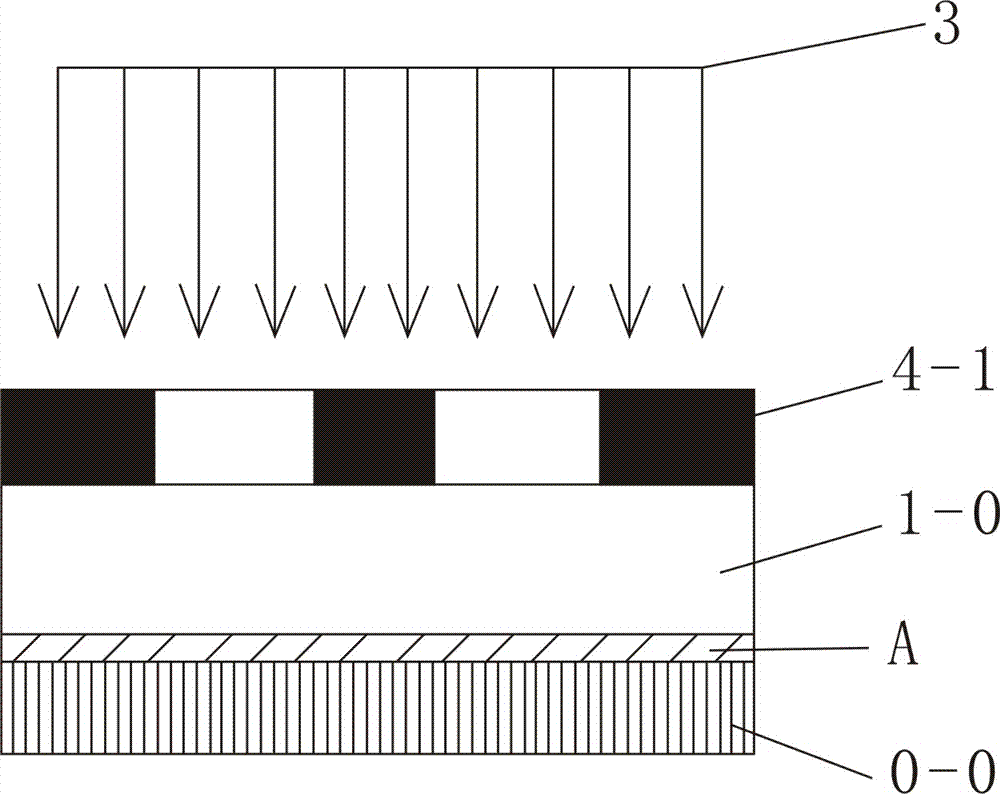

[0043] figure 2 Shown is the special holographic master of splicing the special pattern in the background pattern according to the present invention, and its production method is as follows: image 3 , 4 , 5, first according to the pattern of the master to be made, design and make a film of the corresponding size (including the exposure film 4-1 and the positioning film 4-2); according to the pattern size of the master to be made, a thickness of 0.1~0.2mm transparent PET resin board, cut into transparent large board 1-0;

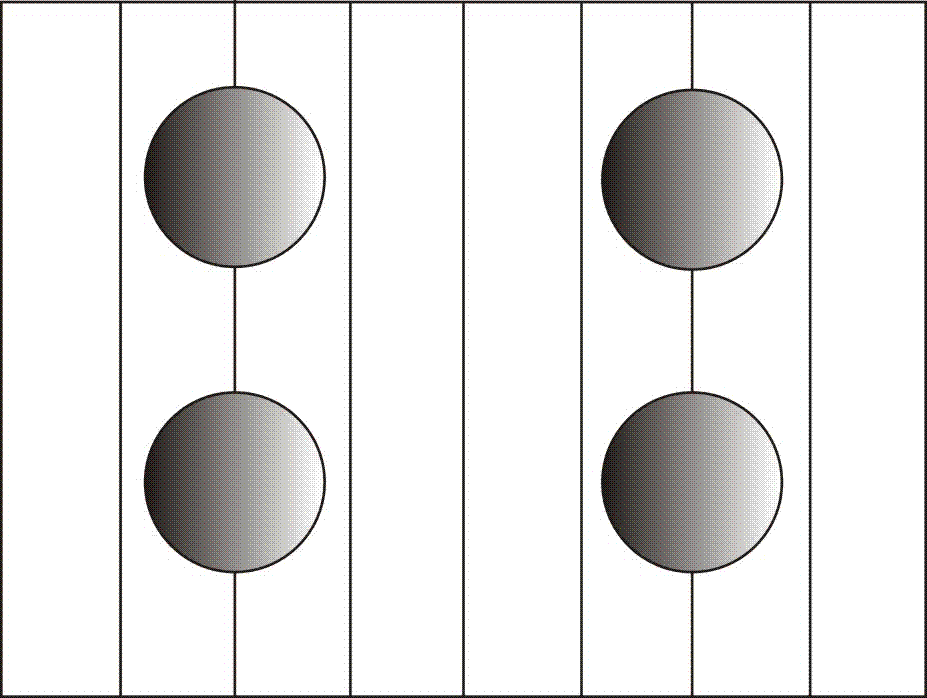

[0044] According to the size of the special nickel plate for unit holography, prepare a corresponding number of small transparent plates 2-0;

[0045] Lay the background pattern nickel plate on the operating platform with the pattern facing upwards, add an appropriate amount of light-curing paint A to the head of the background pattern nickel plate, and then paste the transparent large plate 1-0 with the treatment side facing down Fit on the background p...

Embodiment 2

[0049] Figure 6 Shown is a special holographic master plate composed of a small-area special plate pattern, and its production method is basically the same as that of Example 1:

[0050] First, according to the pattern of the master to be made, design and make a film of the corresponding size (including the exposure film 4-1 and the positioning film 4-2); According to the size of the special nickel plate for unit holography, prepare a corresponding number of small transparent plates 2-0;

[0051] Lay the special nickel plate for unit holography on the operation platform with the pattern facing upwards, add an appropriate amount of light-curing paint B to the head of the nickel plate for unit holography, and then place the transparent small plate 2-0 with the treatment side facing down The method is pasted on the special nickel plate for unit holography, with a small rubber roller at 4~6kg / cm 2 The light-curing coating B is evenly squeezed and filled between the transparent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com