Centralized secondary fermentation method for agaricus bisporus

A technology of secondary fermentation and Agaricus bisporus, which is applied in the fields of organic fertilizer, organic fertilizer preparation, and biological organic part treatment, etc., can solve the problems of small scale, unreasonable formula nutrient distribution ratio, poor quality, etc. The effect of promoting nutrient decomposition and accumulation of available nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

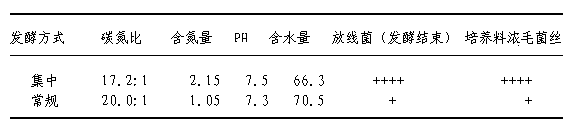

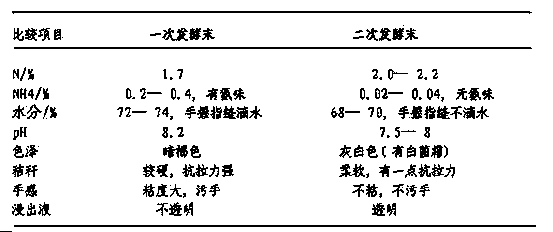

Method used

Image

Examples

Embodiment 1

[0042] 1. One fermentation

[0043] 1.1 Material preparation

[0044] The raw materials of the culture medium are mixed and prepared from the following ingredients: 45 tons of wheat straw, 5 tons of rice straw, 40 tons of chicken manure, 4 tons of gypsum, and 6 tons of oil dry.

[0045] Forage: According to the fermentation process, the length of wheat straw is not required, and the length of straw is 20cm-30cm. The straw is processed by a straw mill. The wheat straw and rice straw are required to be mildew-free and have a water content of 15%-18%.

[0046] Chicken manure: The newly transported chicken manure is placed in the manure storage tank for more than 7 days after being fully stirred to allow it to degrade naturally. The wet chicken manure contains nitrogen (the dry sample contains more than 3.5% nitrogen), the ash content is below 28%, and the water content is 80-85%.

[0047] Gypsum powder: non-crystalline calcium sulfate, purity above 98%, fineness above 100 mesh.

[0048] D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com