Multifunctional explosive mixing and loading truck

A mixed-loading and multi-functional technology, which is applied in the direction of explosives, can solve the problems of high density of emulsion explosives, high unit consumption of explosives, and poor moisture-proof and waterproof performance of ammonium oil explosives, so as to improve operational reliability and simplify pipeline control , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

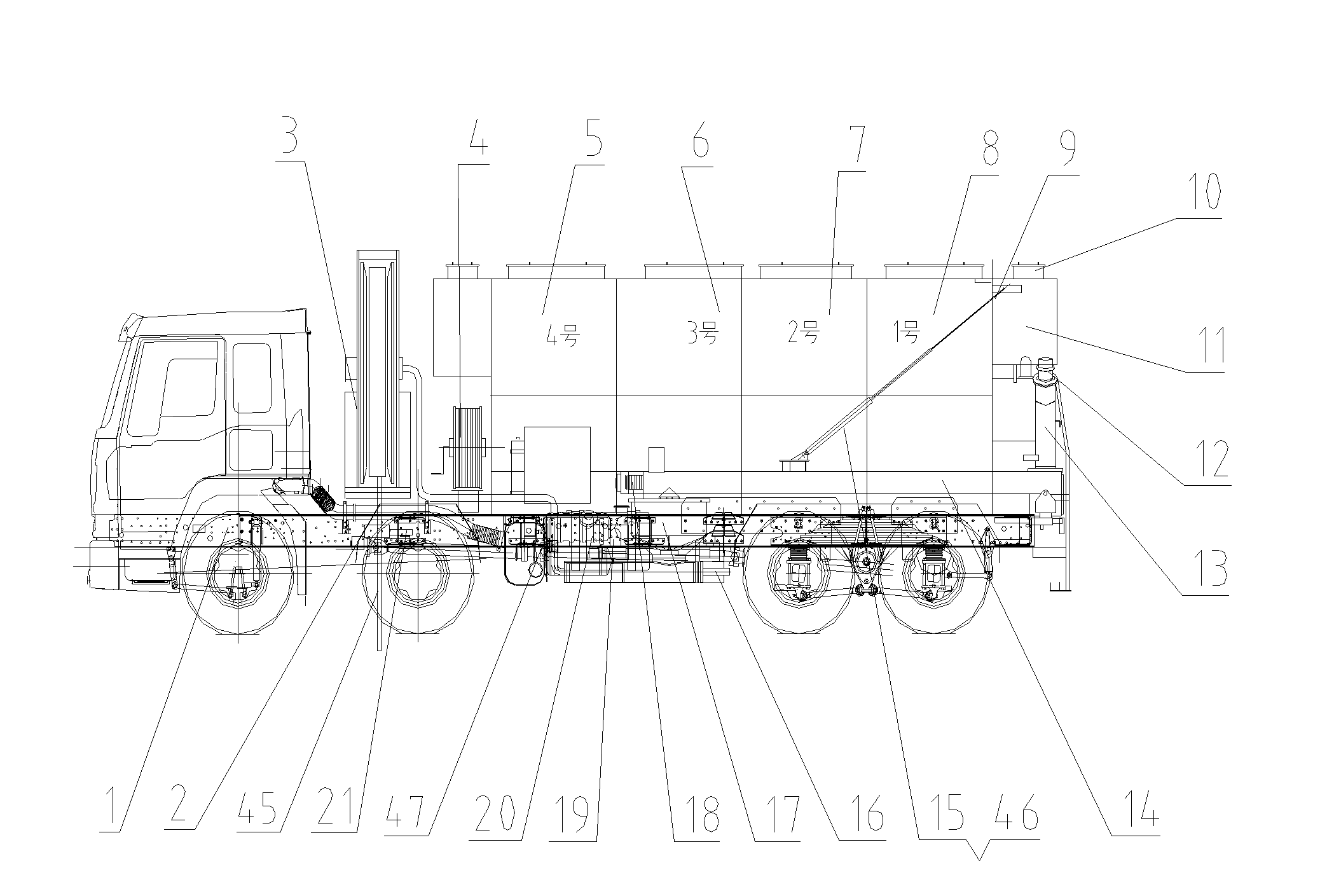

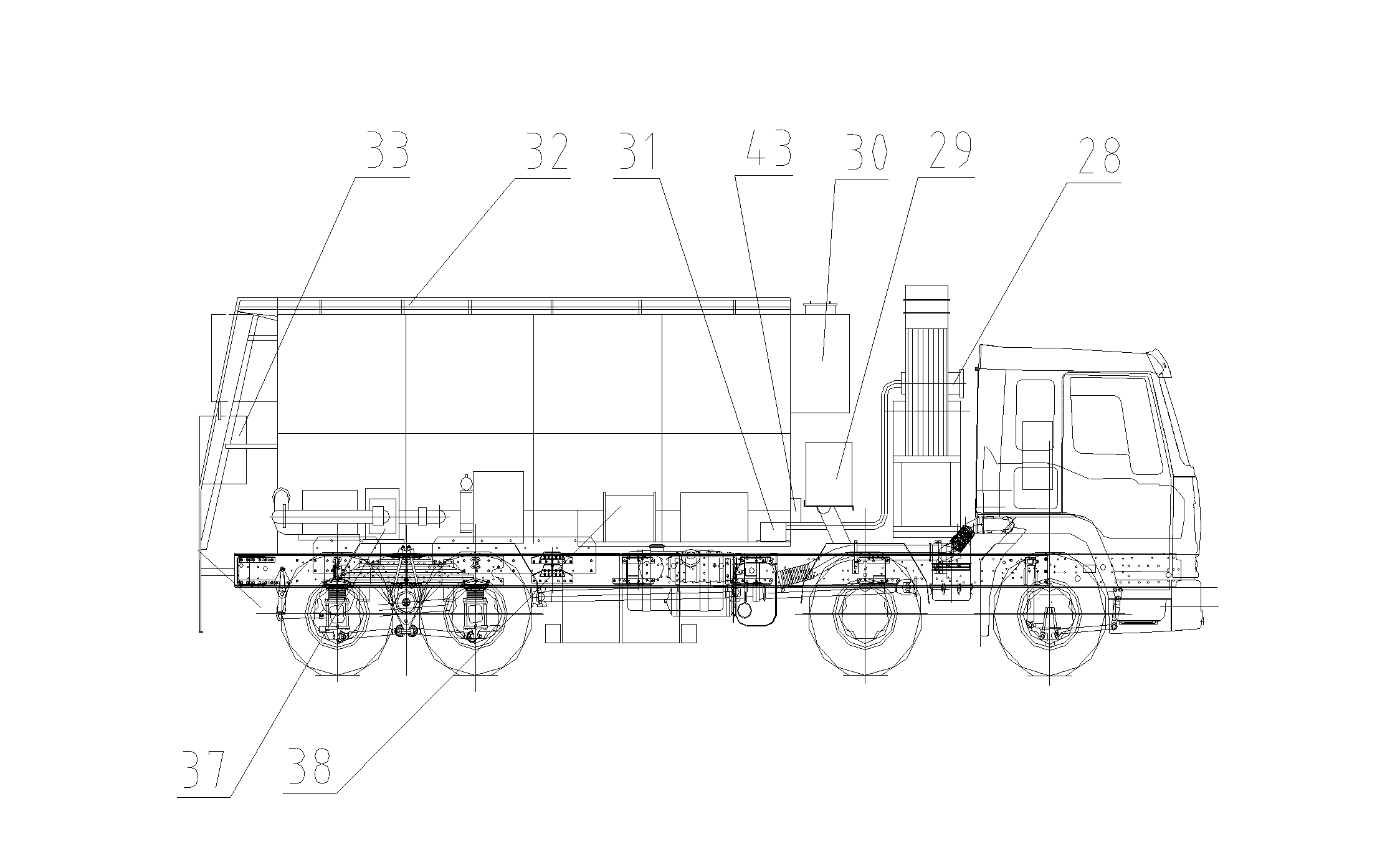

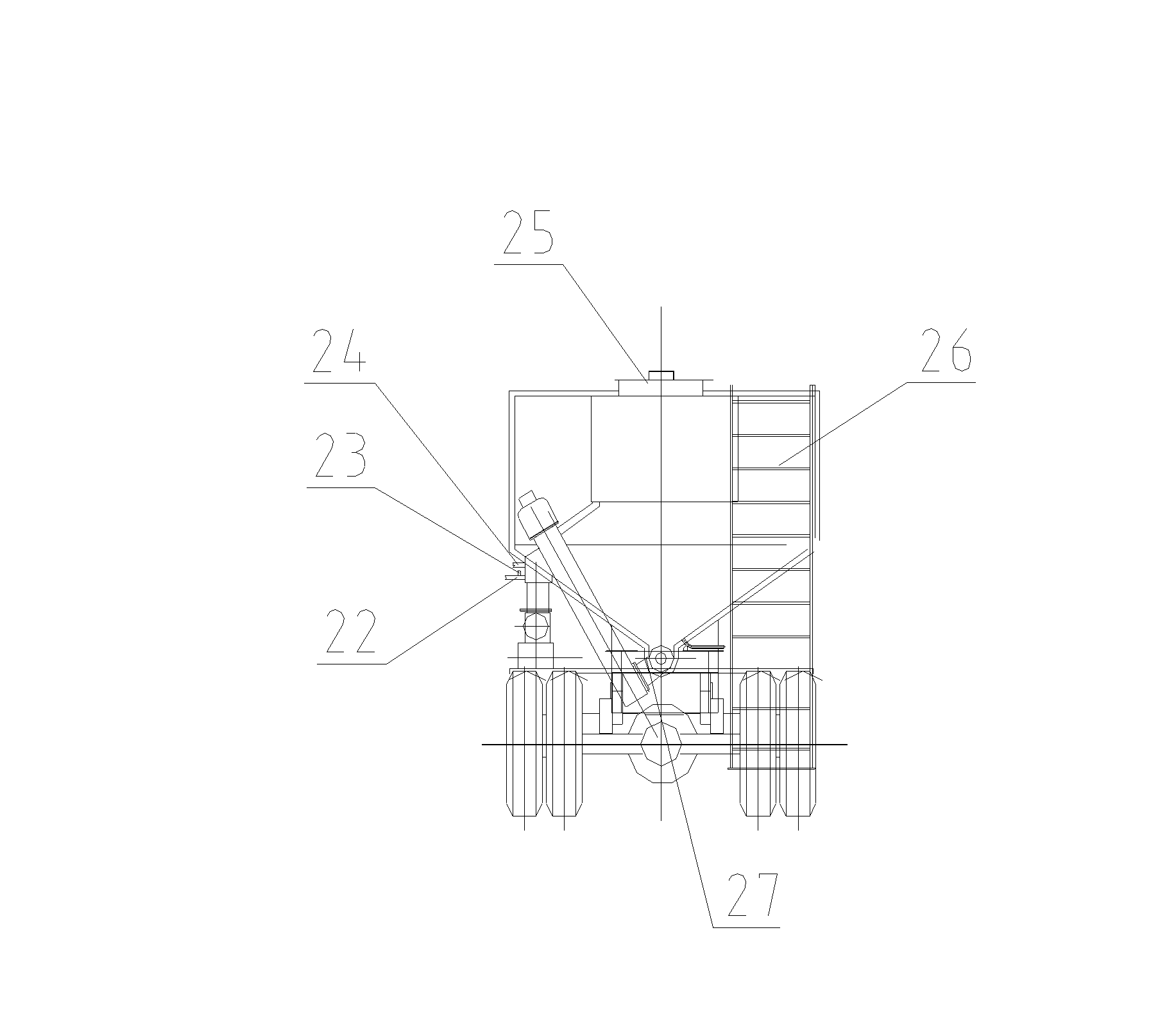

[0046] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown is a schematic structural view of an embodiment of the explosives mixing vehicle of the present invention.

[0047] The explosives mixed truck shown in the picture includes:

[0048] Automobile body and automobile chassis 1, automobile power take-off device 2 connected with automobile speed reducer, automobile power take-off device 2 includes hydraulic pump 21 connected with automobile speed reducer, hydraulic oil splitter, hydraulic oil cooling pump 31, hydraulic pressure Oil filter and hydraulic oil tank 29, in which the hydraulic splitter connects the hydraulic oil generated by the hydraulic pump 21 to different hydraulic motors to output power, and the control elements of the hydraulic oil circuit are collectively arranged in the hydraulic system control cabinet 33.

[0049] The silo part include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com