Method for synthesizing organic salt heat stabilizer

A heat stabilizer and synthesis method technology, applied in the direction of organic chemistry, can solve problems such as unsatisfactory effects, and achieve the effect of slowing down zinc burning and improving the initial coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The synthetic method of organic salt thermal stabilizer of the present invention is as follows:

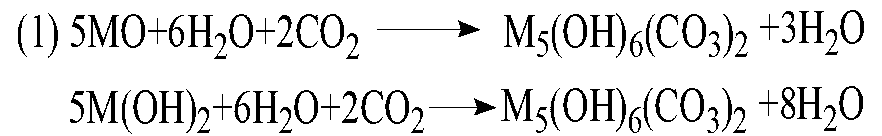

[0029] (1) Add water and zinc oxide in sequence in the kneading kettle, and introduce carbon dioxide to react at a temperature of 120°C. The molar ratio of zinc oxide to water is 1:4, and the molar ratio of zinc oxide to carbon dioxide is 1:0.7, 3 After 1 hour, basic zinc carbonate was obtained.

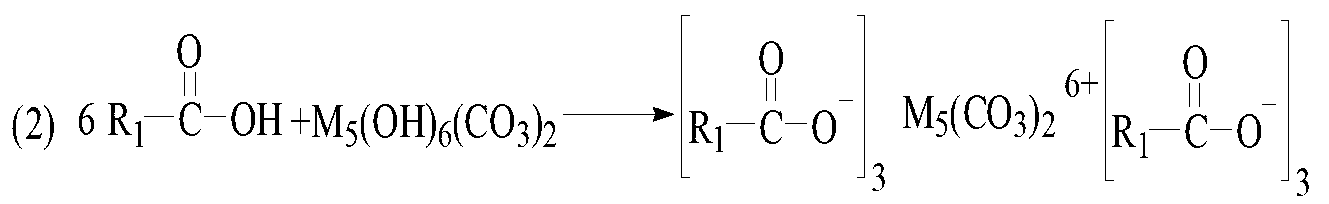

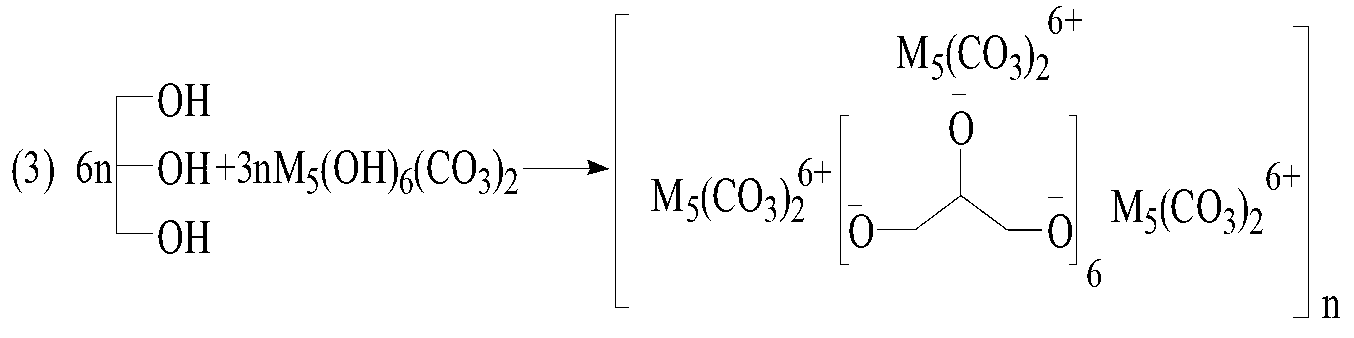

[0030] (2) Add basic zinc carbonate, isooctanoic acid, glycerin and diethylene glycol butyl ether in sequence in the kneading kettle, and react under nitrogen protection at 200°C for 8 hours to obtain a mixed zinc soap of isooctanoic acid / glycerin, basic zinc carbonate and The molar ratio of isooctanoic acid is 1:6.5, the molar ratio of basic zinc carbonate to glycerol is 1:6.5, and the mass ratio of diethylene glycol butyl ether to isooctanoic acid is 1:1.

[0031] (3) Add isooctanoic acid / glycerin mixed zinc soap, isodecyl alcohol, and triphenyl phosphite in sequence in the rea...

Embodiment 2

[0039] The synthetic method of organic salt thermal stabilizer of the present invention is as follows:

[0040] (1) Add water and zinc oxide in sequence in the kneading kettle, and pass in carbon dioxide to react at a temperature of 100°C. The molar ratio of zinc oxide to water is 1:3, and the molar ratio of zinc oxide to carbon dioxide is 1:1,6 After 1 hour, basic zinc carbonate was obtained.

[0041] (2) Add basic zinc carbonate, lauric acid, glycerin and ethylene glycol butyl ether in sequence in the kneading kettle, and react under nitrogen protection at 180°C for 10 hours to obtain lauric acid / glycerin mixed zinc soap, basic zinc carbonate and laurel The molar ratio of acid is 1:6, the molar ratio of basic zinc carbonate to glycerin is 1:6, the mass ratio of butyl glycol ether to lauric acid is 0.8:1, and the mass ratio of butyl glycol ether to lauric acid is 1 :2.

[0042] (3) Add lauric acid / glycerin mixed zinc soap, isotridecanol, 4,4'-isopropyldiphenyl C 12-14 -alc...

Embodiment 3

[0049] The synthetic method of organic salt thermal stabilizer of the present invention is as follows:

[0050] (1) Add water and zinc oxide in sequence in the kneading kettle, pass in carbon dioxide, and react at a temperature of 200 ° C. The molar ratio of zinc oxide to water is 1:5, and the molar ratio of zinc oxide to carbon dioxide is 1:1,5 After 1 hour, basic zinc carbonate was obtained.

[0051] (2) Add basic zinc carbonate, p-tert-butylbenzoic acid, glycerin and dipropylene glycol methyl ether in sequence in the kneading kettle, and react under nitrogen protection at 260°C for 6 hours to obtain p-tert-butylbenzoic acid / glycerin mixed zinc soap, The molar ratio of basic zinc carbonate to lauric acid is 1:7, the molar ratio of basic zinc carbonate to glycerin is 1:7, and the mass ratio of dipropylene glycol methyl ether to lauric acid is 0.6:1.

[0052] (3) Add p-tert-butylbenzoic acid / glycerol mixed zinc soap, isododecanol, tetraphenyldipropylene glycol diphosphite in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com