Liquid heat stabilizer special for cable wires

A heat stabilizer and liquid technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve problems such as foaming, stable body coloring, etc., achieve good synergy, improve initial coloring, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

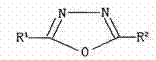

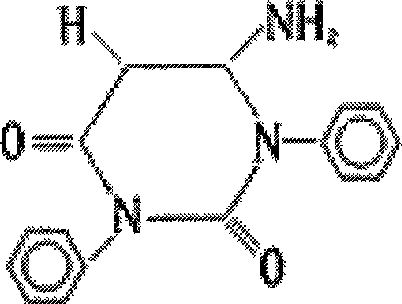

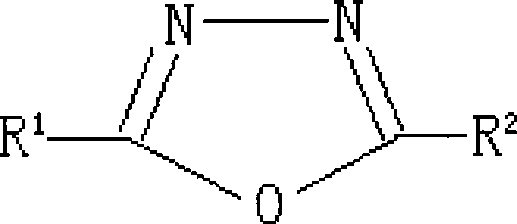

[0027] Embodiment 1: In parts by weight, get respectively 50 parts of calcium carboxylate, 8 parts of zinc carboxylate, 5 parts of magnesium carboxylate, 15 parts of barium carboxylate, 5 parts of diphenylthiourea, 7 parts of sorbitol, 20 parts of phosphite, 0.2 parts of 2,5-diphenyl, 1,3,4-oxadiazole, 2 parts of 6-amino-1,3-diphenyluracil, compounded.

[0028] Organic liquid one-component substances of calcium metal 40-60, organic liquid one-component substances of zinc metal 5-20, organic liquid one-component substances of magnesium metal 5-20, organic liquid one-component substances of barium metal 15- 40, or 5-20, phosphite 5-8, oxadiazole derivatives 0.05-5, aminouracil 1-10.

Embodiment 2

[0029] Embodiment 2: in parts by weight, get respectively 25 parts of calcium carboxylate, 25 parts of zinc carboxylate, 5 parts of magnesium carboxylate, 25 parts of barium carboxylate, 8 parts of stearyl benzene, 3 parts of pentaerythritol, phosphorous acid 30 parts of ester, 2,5-diphenyl, 0.5 parts of 1,3,4-oxadiazole, 4 parts of 6-amino-1,3-diphenyluracil, compounded.

Embodiment 3

[0030] Embodiment 3: in parts by weight, get respectively 25 parts of calcium carboxylate, 25 parts of zinc carboxylate, 5 parts of magnesium carboxylate, 25 parts of barium carboxylate, 3 parts of cadmium carboxylate, 8 parts of stearyl benzene, 3 parts of pentaerythritol, 30 parts of phosphite, 0.5 parts of 2,5-diphenyl, 1,3,4-oxadiazole, 4 parts of 6-amino-1,3-diphenyluracil, compounded .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com