High-strength stainless steel tube with excellent toughness and manufacturing method thereof

A technology of stainless steel pipe and manufacturing method, which is applied in the field of iron-based alloy steel pipe and its manufacture, can solve the problems of poor impact toughness and low toughness of 150 steel grade casing, and achieve the effect of excellent toughness, high strength and good CO2 resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A-J and comparative example a-i

[0049] Produce the excellent high-strength 17Cr stainless steel pipe of toughness described in the present invention according to the following steps:

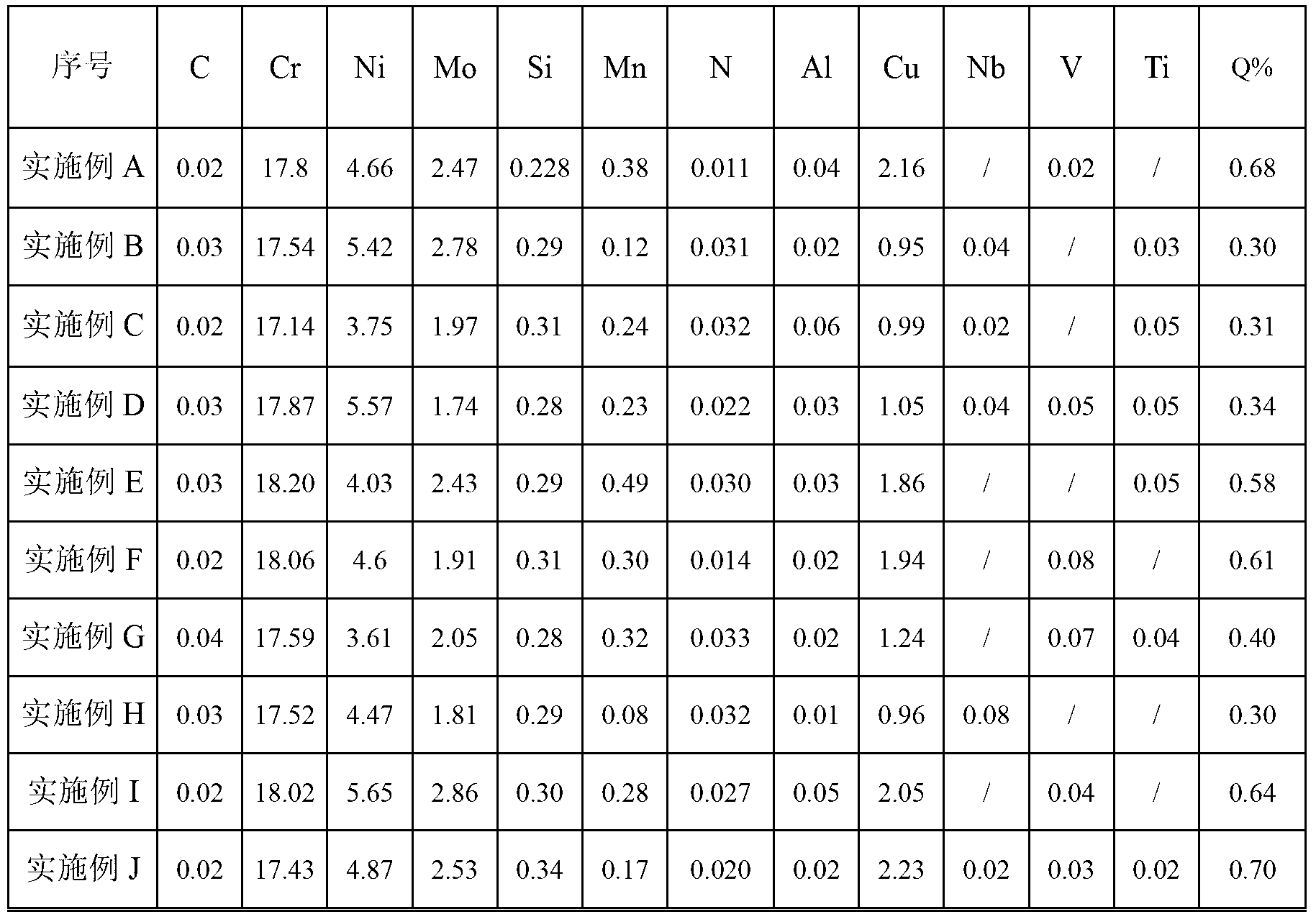

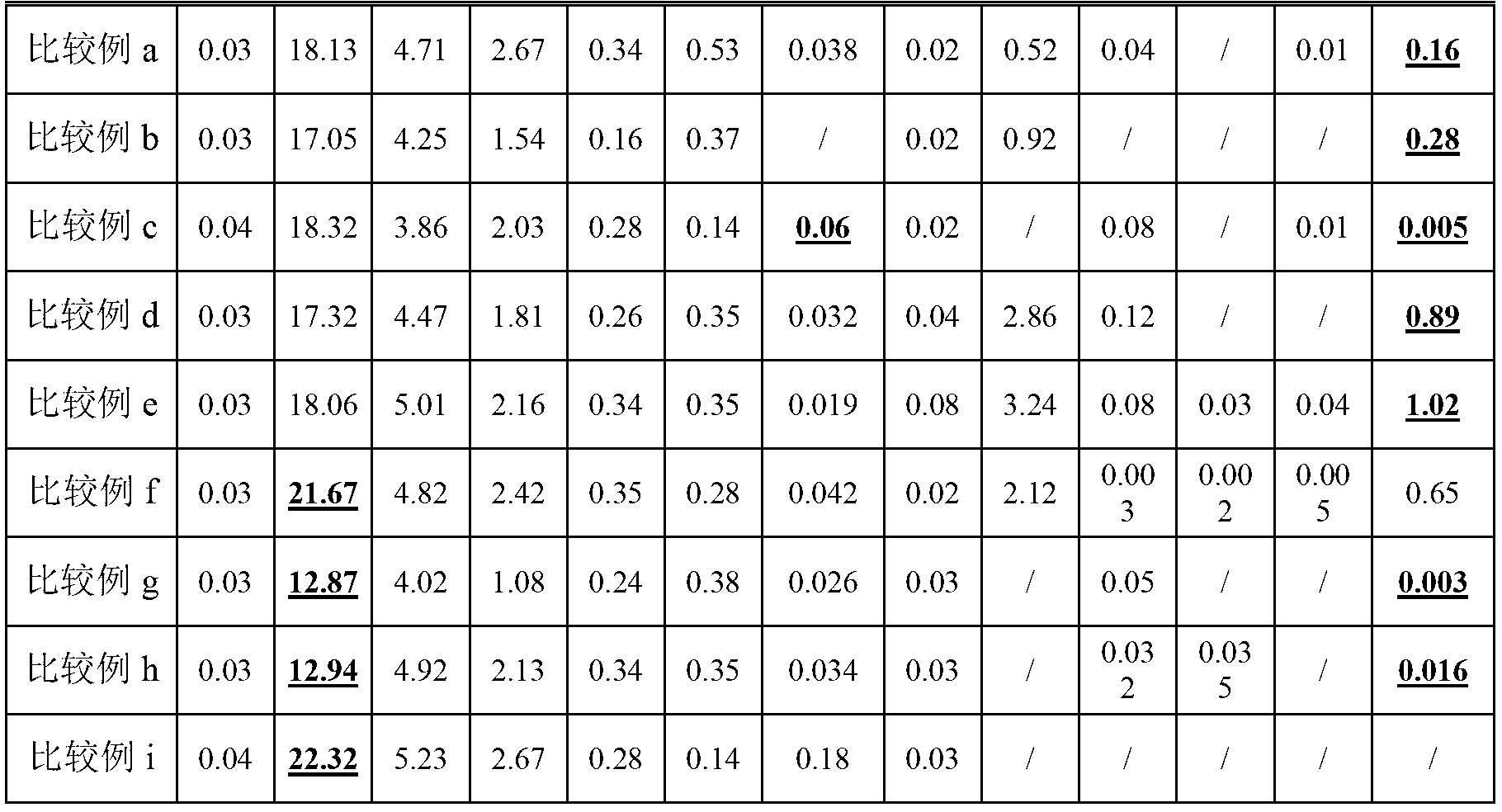

[0050] 1) Smelting: smelting and controlling the proportion of each chemical element as shown in Table 1;

[0051] 2) Casting: casting molten steel into steel ingots;

[0052] 3) Forging into round tube billet;

[0053] 4) Annealing: Anneal the tube blank at a temperature of 640-720 °C;

[0054] 5) Heating: Heat the tube blank to 1050-1250°C, and the heating time is 1-3h;

[0055] 6) After piercing, hot rolling and sizing, it is made into a blank tube;

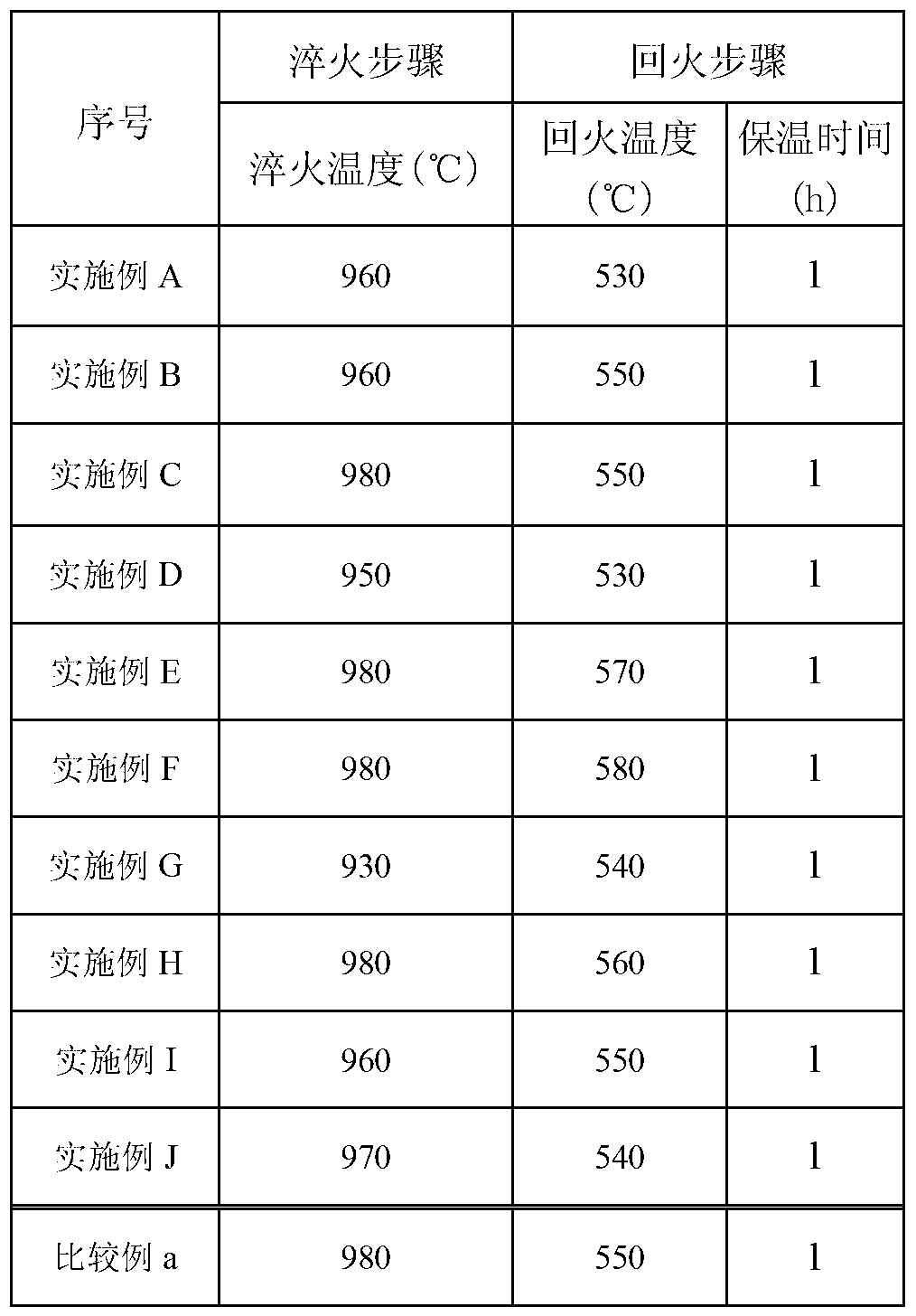

[0056] 7) Quenching: heat the steel pipe to a temperature of 900-1000°C and keep it for 40 minutes, then cool it with water;

[0057] 8) Tempering: Temper the steel pipe at a temperature of 500-640°C, and the tempering holding time is ≤2h to obtain a stainless steel pipe of 114.3mm*12.7mm.

[0058] Table 1 shows the mass percentage distribution of each chemical element in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Uniform corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com