Long-life low-foaming cleaning and antirust two-in-one metal cleaner

A metal cleaning agent, long-life technology, applied in the field of long-life, low-foam cleaning and anti-rust two-in-one metal cleaning agents, can solve the problems of short service life, good anti-rust performance and poor cleaning effect of metal cleaning agents, and achieve convenient High-pressure jet cleaning, strong detergency, and long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

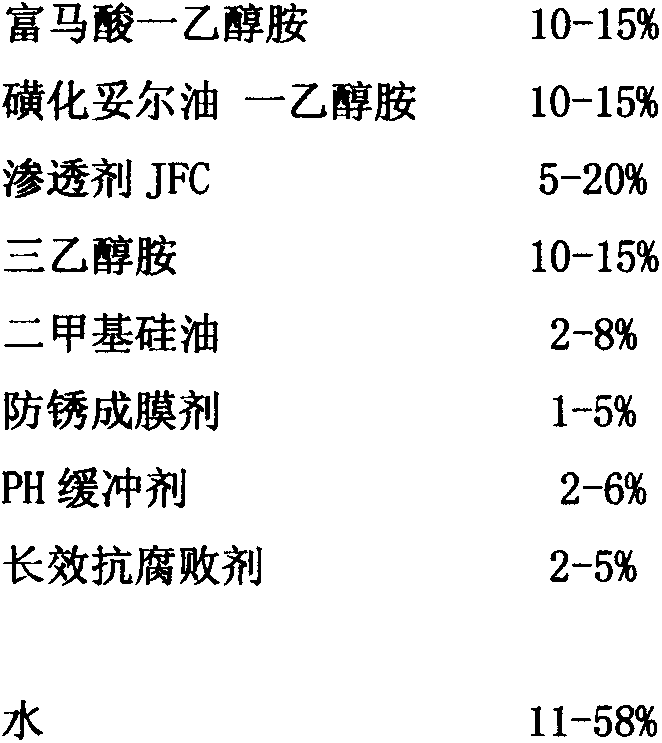

[0008] The long-life and low-foaming "cleaning and anti-rust two-in-one" metal cleaning agent of the present invention is prepared by the following ingredients in percentage by weight:

[0009]

[0010] The preparation process is as follows:

[0011] 1. Configure anti-rust film-forming agent: dimethyl dodecenyl succinate and calcium petroleum sulfonate (1:1)

[0012] 2. Configure pH buffer: borax: potassium hydrogen phthalate: sodium phosphate = 1:0.6:1

[0013] 3. Configure long-acting anti-corruption agent: dibenzyl fumarate and diethyl fumarate (1:1)

[0014] 4. Warm the water to 80°C, put in various auxiliary materials, stir and mix evenly, if there is uneven turbidity, add 2% sodium petroleum sulfonate (percentage by weight) to adjust its transparency until the appearance of the product is transparent and uniform.

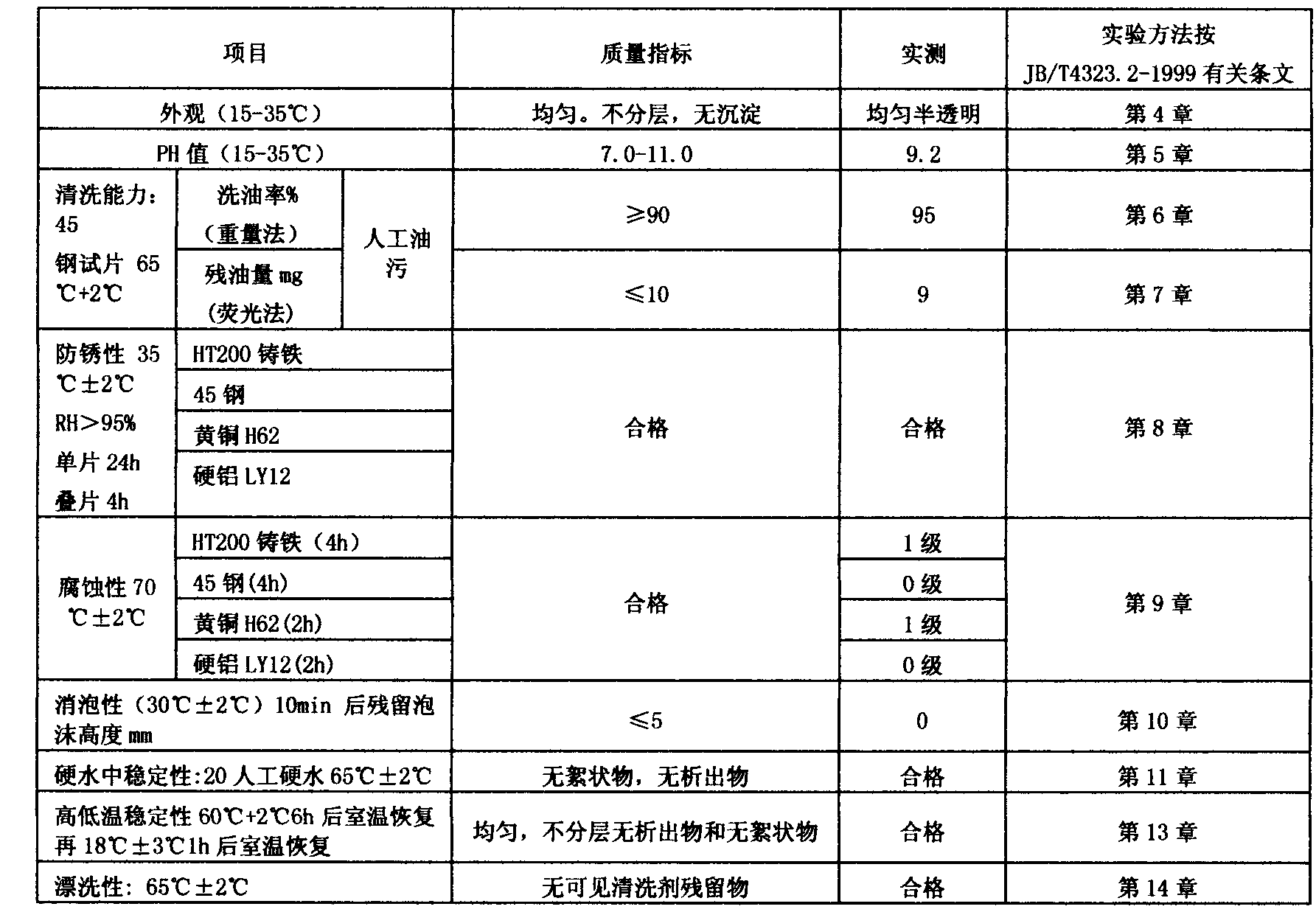

[0015] Product performance and test method

[0016]

Embodiment 2

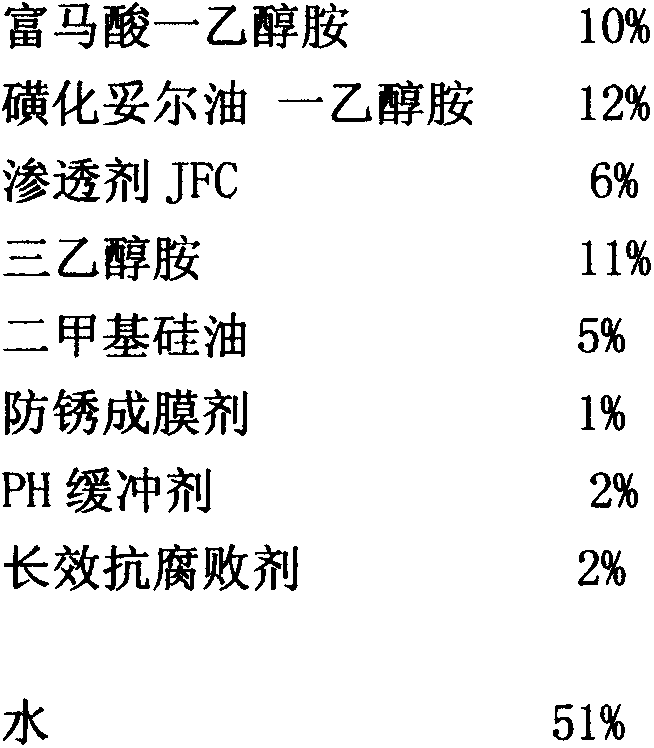

[0018] The long-life and low-foaming "cleaning and anti-rust two-in-one" metal cleaning agent of the present invention is prepared from the following ingredients by weight percentage

[0019]

[0020] The preparation process is as follows:

[0021] 1. Configure anti-rust film-forming agent: dimethyl dodecenyl succinate and calcium petroleum sulfonate (1:1)

[0022] 2. Configure pH buffer: borax: potassium hydrogen phthalate: sodium phosphate = 1:0.6:1

[0023] 3. Configure long-acting anti-corruption agent: dibenzyl fumarate and diethyl fumarate (1:1)

[0024] 4. After heating the water to 80°C, put in various additive raw materials, stir and mix evenly, without turbidity, and the appearance is transparent and uniform, and then the material can be discharged.

[0025] Product performance and test method

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com