Determination method for content of silicon in high strength aluminum welding wire

A measurement method, the technology of aluminum welding wire, applied in the field of analysis and testing, can solve the problems of inapplicability to pre-furnace analysis and mass product testing, long test process, and high technical level requirements for testing personnel, etc., with short time to achieve and few reagent methods , time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

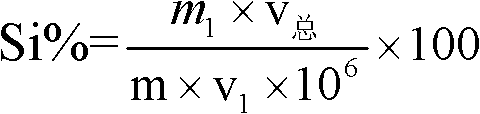

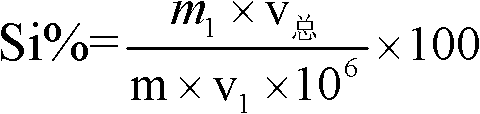

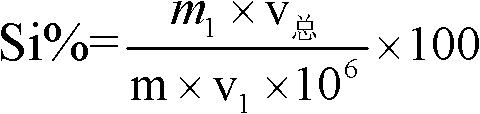

[0070] 1. Accurately weigh 0.2000g of high-strength aluminum welding wire sample into a 100mL silver beaker, add a small amount of water (2mL) and 5g of sodium hydroxide, add 10mL of water after a violent reaction, heat until the sample is completely dissolved, and cool. Wash the silver watch glass and cup wall with water, transfer the sample solution into a beaker filled with 50ml nitric acid (1+1) under stirring; heat the sample solution in the beaker to boil, drive off nitrogen oxides, and cool. Transfer to a 250mL volumetric flask, dilute to the mark, and shake well.

[0071] 2. Dispense 5.00mL of the above solution into a 100mL colorimetric tube, add 1mL of nitric acid (1+1), add 5.00mL of ammonium molybdate solution, the mass concentration of ammonium molybdate solution is 5%, boil in a water bath for 30s, and cool in running water. Add 40 mL of sulfuric acid-ammonium oxalate solution, 10 mL of 6% ferrous ammonium sulfate solution, dilute to the mark with deionized water...

Embodiment 2

[0092] 1. Accurately weigh 0.2000g of a high-strength aluminum welding wire sample into a 100mL silver beaker, add a small amount of water (2ml) and 5g of sodium hydroxide, add 10mL of water after a violent reaction, heat until the sample is completely dissolved, and cool. Wash the silver watch glass and cup wall with water, transfer the sample solution into a beaker filled with 50ml nitric acid (1+1) under stirring; heat the sample solution in the beaker to boil, drive off nitrogen oxides, and cool. Transfer to a 250mL volumetric flask, dilute to the mark, and shake well.

[0093] Add 40 mL of sulfuric acid-ammonium oxalate solution, 10 mL of ferrous ammonium sulfate solution, dilute to the mark with deionized water, shake well and measure.

[0094] 2. Dispense 5.00mL of the above solution into a 100mL colorimetric tube, add 1mL of (1+1) nitric acid, add 5.00mL of ammonium molybdate solution, the mass concentration of ammonium molybdate solution is 5%, boil in water bath for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com