Redox flowing method of vanadium redox flow galvanic pile and galvanic pile

A technology of liquid flow electricity and vanadium liquid, which is applied in the field of vanadium batteries, can solve the problems of unstable electrical performance of the stack, reduced flow rate of the liquid outlet, and voltage drop, etc., to provide electrical performance and stability, improve the overall electrical performance, Even effect of circulation and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

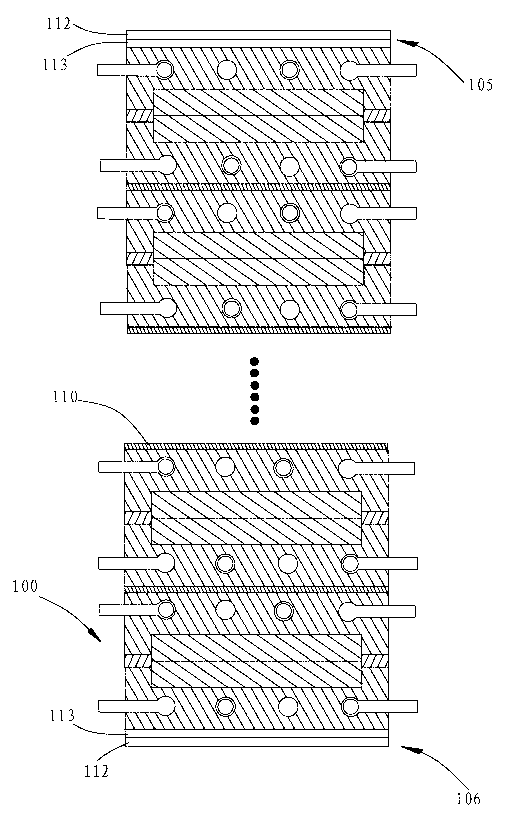

[0018] The invention provides a liquid flow method of a vanadium liquid flow stack. The liquid flow method of the vanadium liquid flow stack uses each stack unit in the vanadium liquid flow stack as an independent vanadium liquid circulation system.

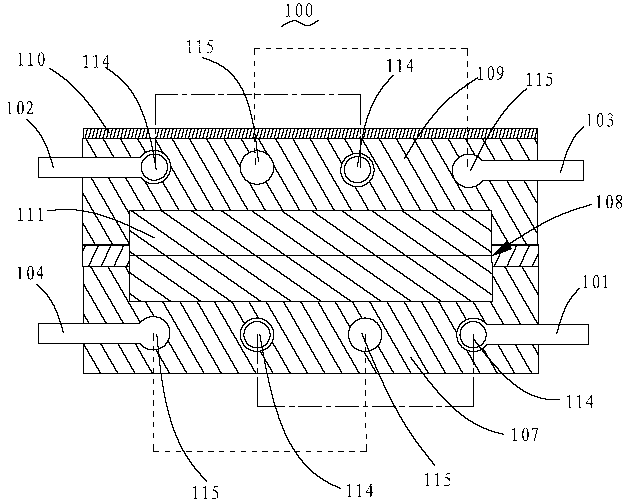

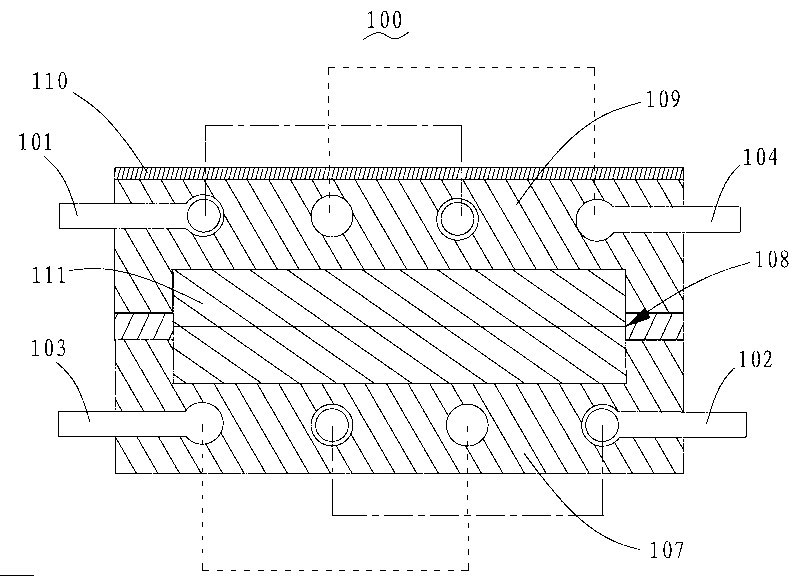

[0019] Specifically, the liquid inlet 101 of the positive vanadium liquid and the liquid outlet 104 of the negative vanadium liquid are set on the first working surface of each stack unit 100, and the second working surface of the stack unit 100 is set The liquid outlet 102 of the positive vanadium liquid and the liquid inlet 103 of the negative vanadium liquid, the liquid inlet 101 of the positive vanadium liquid is connected with the liquid outlet 102 of the positive vanadium liquid through the first flow channel, so The liquid inlet 103 of the negative vanadium liquid is connected with the liquid outlet 104 of the negative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com