Electric blanket for indoor heating

An electric heating blanket and working medium technology, which is applied in household heating, electric heating systems, sleeping blankets, etc., can solve the problems of low thermal efficiency, high local temperature, and low thermal efficiency of electric heating devices, achieve low production costs, reduce heat dissipation, The effect of high heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

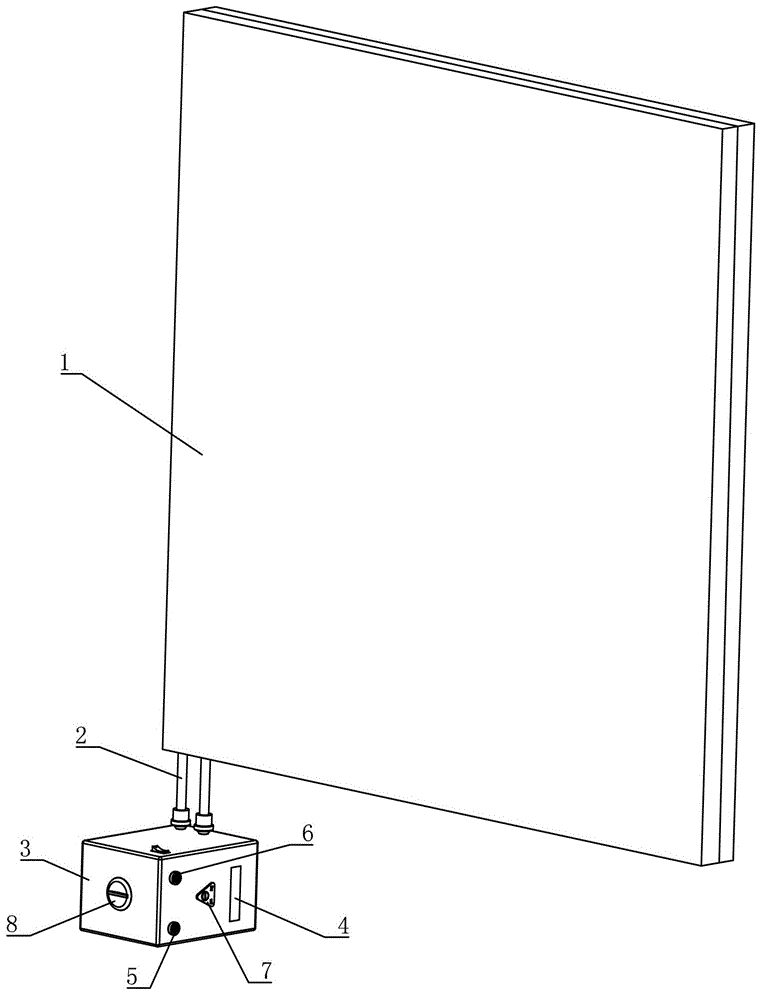

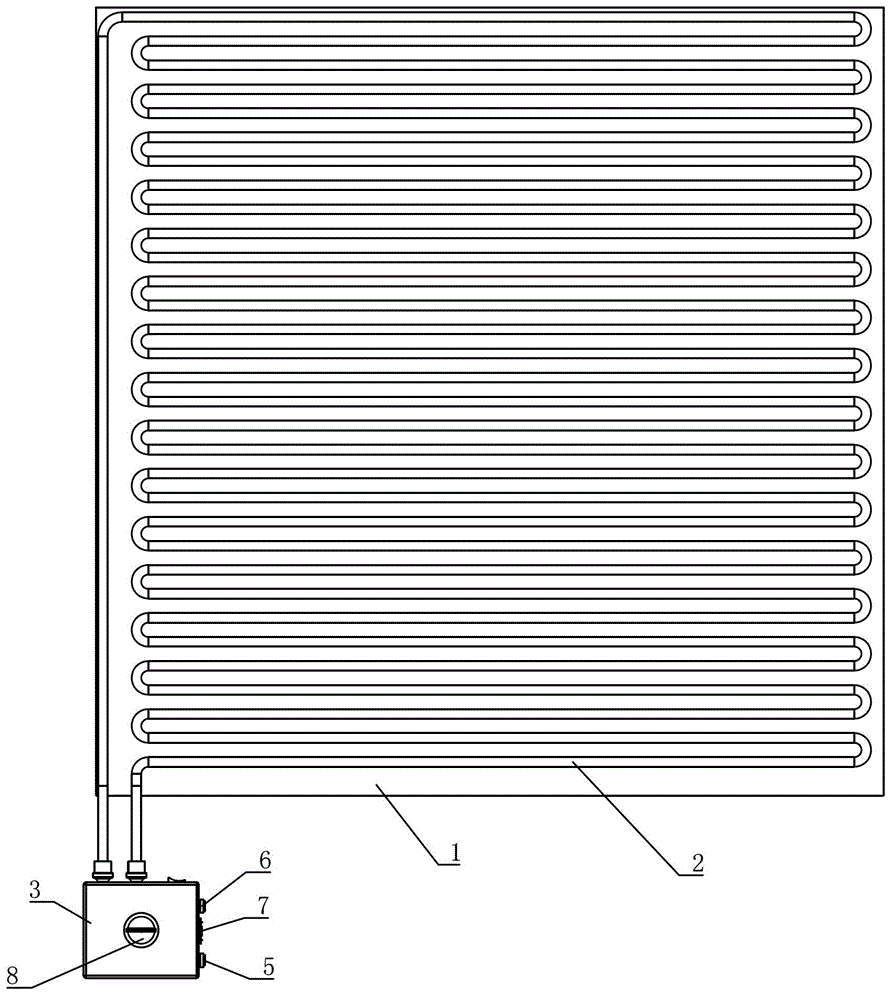

[0022] refer to figure 1 and figure 2 , an electric blanket for indoor heating of the present invention can be used as both a carpet and a mattress, comprising

[0023] The braided fabric 1 specifically includes a bottom layer and a covering layer covered on the bottom layer;

[0024] The organic hose 2 is arranged inside the braid 1 and bent into a serpentine shape, and is filled with a liquid working medium;

[0025] The working medium container 3 is equipped with an electric heater 4 for heating, and is provided with an injection port for filling the working medium. The working medium container 3 and the two ends of the organic hose 2 are hermetically connected to form a closed space, and the working medium After being heated, it circulates in the closed space by means of pulsating conduction and heat energy transmission.

[0026] The working fluid of the present invention is heated by the electric heater 4, and conducts the heat it absorbs to the braid 1 through the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com