Mobile Modular Self-Reconfigurable Robot

A mobile module and self-reconfiguration technology, applied in the field of robotics, can solve problems such as wheel vacating, affecting function realization, and single module independent movement restrictions, so as to improve flexibility and adaptability, prolong service life, and improve transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

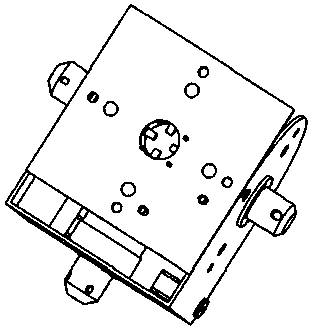

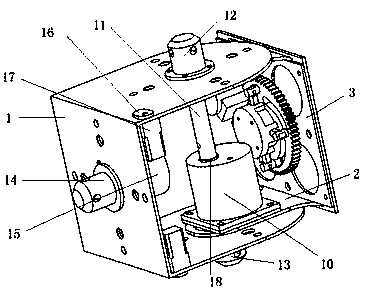

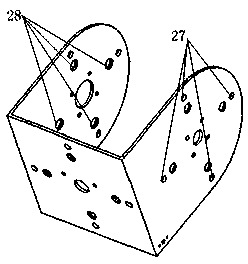

[0036] like figure 1 , figure 2 As shown, the mobile modular self-reconfigurable robot is a 100*100*122 cuboid, including a U-shaped outer frame 1, a U-shaped inner frame 2, and a motor frame 10 , a first stepper motor 4, a second stepper motor 18, a third stepper motor 15, two DC motors 17, an inner frame coupling 11, an active connection mechanism, three passive connection mechanisms, That is, the first passive connection mechanism 12, the second passive connection mechanism 13, the third passive connection mechanism 14, two driving legs 16, the two driving legs 16 of the movable modular self-reconfigurable robot rotate continuously in the same direction in the DC motor 17 Next, rely on the friction with the ground to drive the module to move back and forth, and the two driving legs 16 drive the module to turn and move under the reverse continuous rotation of the DC motor 17, relying on the friction with the ground.

[0037] This module can be driven by the second st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com