Desulfurization gypsum sand pulp

A technology of desulfurized gypsum and mortar, which is applied in the field of building materials, can solve the problems of environmental pollution caused by industrial waste residues, achieve the effects of improving work performance and mechanical properties, fast construction, and controlling environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

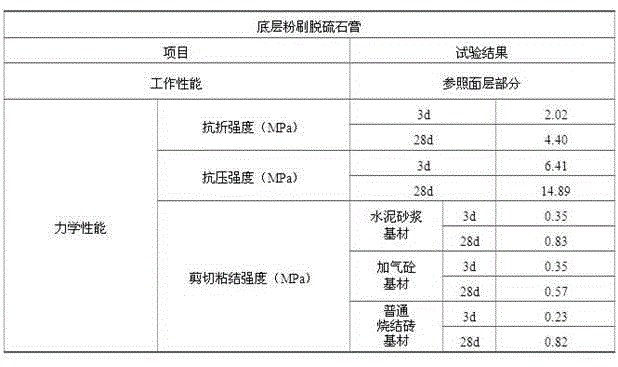

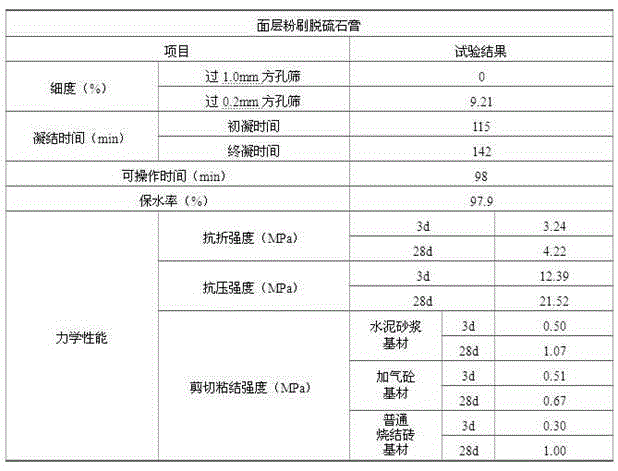

[0008] Embodiment 1: The desulfurized gypsum mortar includes two types of desulfurized gypsum painted on the surface layer and desulfurized gypsum painted on the bottom layer. The desulfurized gypsum painted on the surface layer includes: desulfurized gypsum, SC gypsum retarder, fly ash and cellulose ether, desulfurized gypsum Gypsum is 79.6%, SC gypsum retarder is 0.35%, fly ash is 20%, and hydroxypropyl methyl cellulose ether is 0.010%, all of which are percentages by weight; the bottom plastering desulfurization gypsum includes: desulfurization gypsum is 79.6%, SC gypsum retarder 0.35%, fly ash 20%, cellulose ether 0.010% and river sand, according to desulfurization gypsum, SC gypsum retarder, fly ash and cellulose ether mixture and sand The ratio is 1:2, which is a percentage by weight.

[0009] The standard water consumption of desulfurization gypsum painted on the surface is 35%, and the standard water consumption of desulfurized gypsum painted on the bottom layer is 60%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com