Diachylon of negative electrode of lead carbon battery and manufacturing method thereof

A negative electrode lead paste, lead carbon battery technology, applied to battery electrodes, circuits, electrical components and other directions, can solve the problems affecting the stability of the electrode plate paste, the carbon material is difficult to uniformly disperse, and the lead powder space is occupied, and the operation is simple and convenient. , The effect of high current performance and strong charging acceptance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2、3

[0031] The preparation method of embodiment 1,2,3 is as follows:

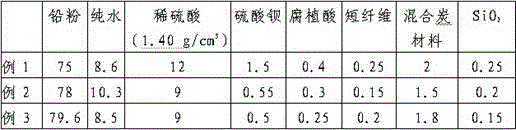

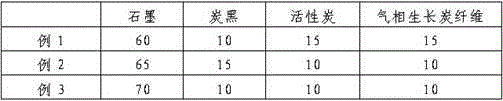

[0032] (1) Material preparation: prepare materials according to the distribution ratio of each component in Table 1 and Table 2;

[0033] (2) Premixing: barium sulfate, humic acid, short fibers, mixed carbon materials, SiO 2 Add it into the mixing tank of the paste machine, dry stirring (Example 1: 5min; Example 2: 6min; Example 3: 8min);

[0034] (3) Dry mixing: Then add lead powder, dry mixing (Example 1: 5min; Example 2: 4min; Example 3: 3min), and at the same time turn on the paste cooling system;

[0035] (4) Add water: Then add pure water, finish adding within 1 minute, and stir after adding water (Example 1: 4min; Example 2: 3min; Example 3: 5min);

[0036] (5) Acid addition: add dilute sulfuric acid and stir at the end, and at the same time open the mixing paste ventilation system, add acid speed (Example 1: 9kg / min; Example 2: 10kg / min; Example 3: 10kg / min); control the mixing paste temperature (Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com