Preparation method of polybutylene terephthalate

A technology of polybutylene terephthalate and butanediol, which is applied in the field of polyester, can solve the problems of affecting the operation of the reaction equipment system, high catalyst consumption, and fouling of pipeline equipment, etc., so as to suppress the deterioration of the hue and achieve a good hue , The effect of low carboxyl-terminal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

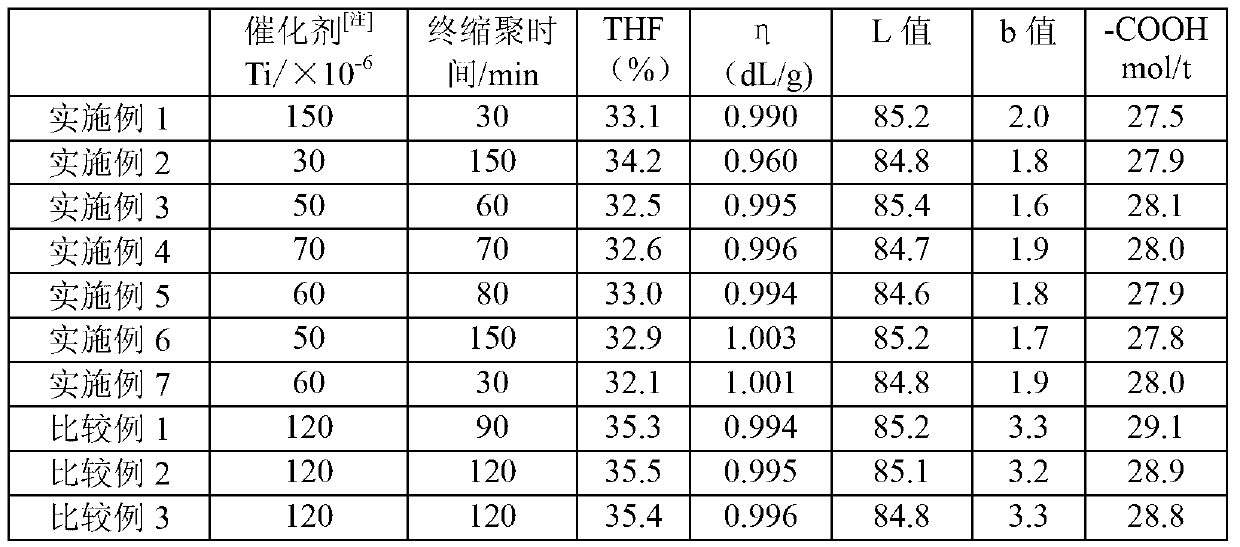

Examples

Embodiment 1

[0047] (A) PBT slices were synthesized in a 2L reactor. Mix 500g of terephthalic acid (PTA) and 569g of 1,4-butanediol (BD) evenly, the molar ratio is PTA:BD=1:2.1, add liquid titanium catalyst 150×10 -6 (Based on the content of titanium atomic mass in the total weight of polyester produced). Gradually raise the temperature from 190°C to 230°C, the absolute reaction pressure is 101325Pa (gauge pressure is 0), and the esterification reaction is carried out, and the reaction time is 1 hour;

[0048] (B) After the esterification reaction is finished, a sufficient amount of distillate is distilled off, and the pre-condensation reaction is started by vacuuming. The reaction temperature is gradually increased from 230°C to 250°C, and the reaction pressure is gradually reduced from an absolute pressure of 101kPa to 600Pa. The polycondensation time is 0.5 hour;

[0049] (C) The final polycondensation reaction was carried out at 260°C and an absolute pressure of 50 Pa. After 30 minut...

Embodiment 2

[0051] (A) PBT slices were synthesized in a 2L reactor. Mix 500g of terephthalic acid (PTA) and 406g of 1,4-butanediol (BD) evenly, the molar ratio is PTA:BD=1:1.5, add liquid titanium catalyst 30×10 -6 (Based on the content of titanium atomic mass in the total weight of polyester produced). Gradually raise the temperature from 190°C to 230°C, the absolute reaction pressure is 101325Pa (gauge pressure is 0), and the esterification reaction is carried out, and the reaction time is 5 hours;

[0052] (B) After the esterification reaction is finished, a sufficient amount of distillate is distilled off, and the pre-condensation reaction is started by vacuuming. The reaction temperature is gradually increased from 230°C to 250°C, and the reaction pressure is gradually reduced from an absolute pressure of 101kPa to 600Pa. The polycondensation time is 1.5 hours;

[0053] (C) The final polycondensation reaction was carried out at 250°C and an absolute pressure of 150 Pa. After 150 mi...

Embodiment 3

[0055] (A) PBT slices were synthesized in a 2L reactor. Mix 500g of terephthalic acid (PTA) and 460g of 1,4-butanediol (BD) evenly, the molar ratio is PTA:BD=1:1.7, add liquid titanium catalyst 50×10 -6 (Based on the content of titanium atomic mass in the total weight of polyester produced). Gradually raise the temperature from 190°C to 230°C, the absolute reaction pressure is 101325Pa (gauge pressure is 0), and the esterification reaction is carried out, and the reaction time is 2 hours;

[0056] (B) After the esterification reaction is finished, a sufficient amount of distillate is distilled off, and the pre-condensation reaction is started by vacuuming. The reaction temperature is gradually increased from 230°C to 250°C, and the reaction pressure is gradually reduced from an absolute pressure of 101kPa to 600Pa. The polycondensation time is 0.5 hour;

[0057] (C) The final polycondensation reaction was carried out at 250°C and an absolute pressure of 70 Pa. After 60 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com