Preparation method of trichlorophenol blocked isocyanate prepolymer micelle

A technology of blocked isocyanate and trichlorophenol, which is applied in the direction of adhesives, adhesive types, polyurea/polyurethane coatings, etc., and can solve problems such as limiting the application of low-temperature bonding occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Embodiment 1: The isocyanate in this embodiment is hexamethylene diisocyanate (HDI), and the preparation method of trichlorophenol-blocked isocyanate prepolymer micelles is carried out according to the following steps:

[0027] Step 1, drying the polyethylene glycol in vacuum at 120° C. for 3 hours;

[0028] Step 2: Add 0.0183mol of polyethylene glycol treated in Step 1, 0.0071mol of 2,2-dimethylolpropionic acid (DMPA), and 10mL of composite solvent into a four-necked flask, and mechanically stir and mix at a speed of 105r / min for 30min , the composite solvent is a mixture of acetone and methyl ethyl ketone at a volume ratio of 1:3, and then nitrogen is passed through at a flow rate of 5mL / min for 30 minutes, heated to 70°C, and kept for 29 minutes;

[0029] Step 3. Add 0.0276 mol of hexamethylene diisocyanate (HDI) dropwise to the four-necked bottle at a rate of 4 drops / s. After the dropwise addition, raise the temperature to 84°C, keep the temperature for 3.2 hours, a...

specific Embodiment approach 2

[0040] Specific embodiment two: The isocyanate of this embodiment is toluene-2,4-diisocyanate (TDI), and the preparation method of trichlorophenol-blocked isocyanate prepolymer micelles is carried out according to the following steps:

[0041] Step 1, drying the polyethylene glycol in vacuum at 120° C. for 3 hours;

[0042] Step 2: Add 0.0169 mol of polyethylene glycol treated in step 1, 0.0106 mol of 2,2-dimethylolpropionic acid (DMPA), and 13 mL of composite solvent into a four-necked flask, and mechanically stir and mix at a speed of 105 r / min for 30 min , the composite solvent is a mixture of acetone and methyl ethyl ketone at a volume ratio of 1:3, and then nitrogen is passed through at a flow rate of 5mL / min for 30 minutes, heated to 70°C, and kept for 25 minutes;

[0043] Step 3. Then add 0.0305 mol of toluene-2,4-diisocyanate (TDI) dropwise to the four-necked bottle at a rate of 2-3 drops / s. After the dropwise addition, the temperature is raised to 80°C, and the temper...

PUM

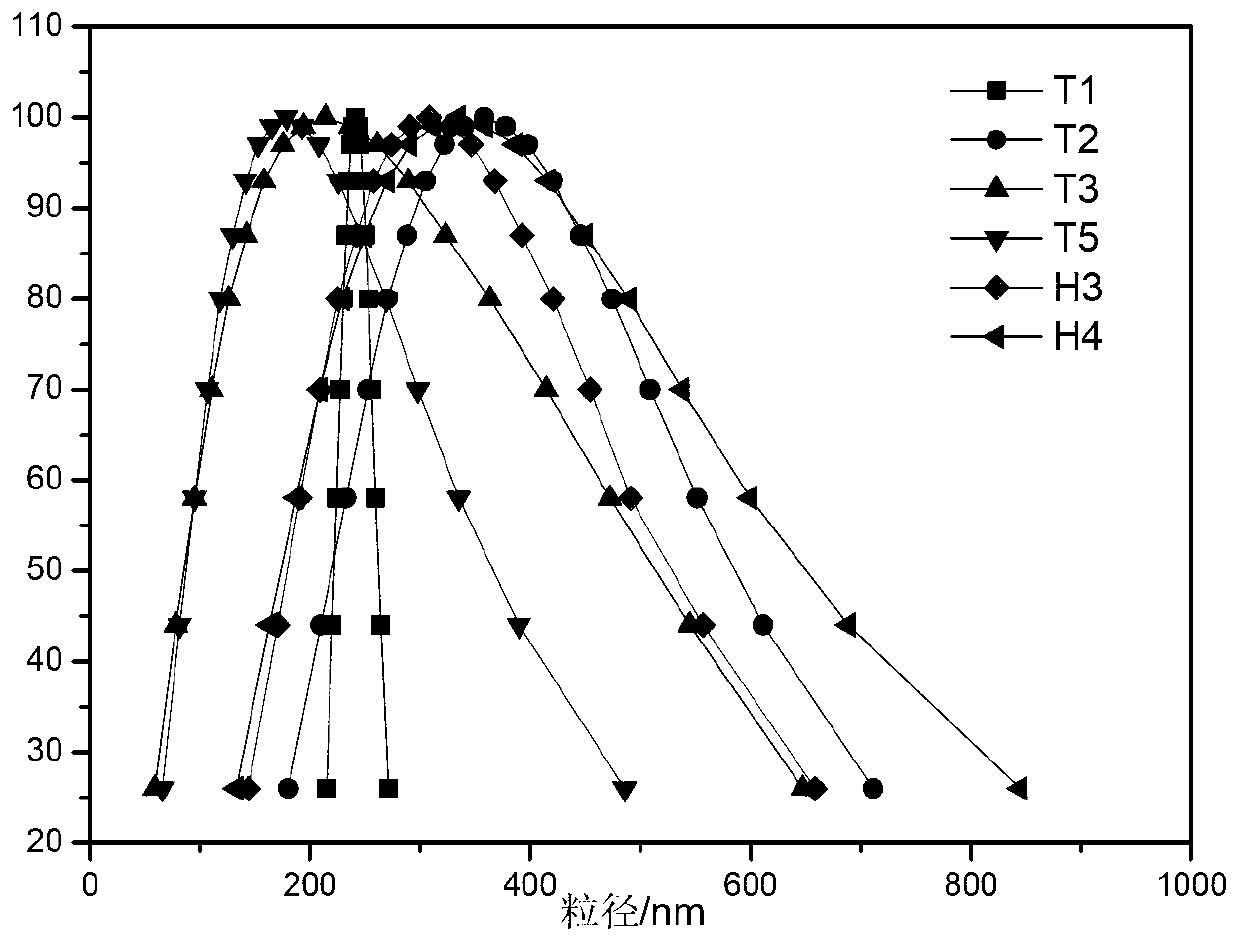

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com