Short-term high-temperature resistant acrylic-based composition and method for preparing heat conducting fin by using same

An acrylic-based, short-term high-temperature technology, applied in the direction of polymer adhesive additives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem of no obvious change in surface viscosity and thermal conductivity, There is no mention of the softness and hardness of the acrylic heat conduction sheet, and the effect of good softness and hardness is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

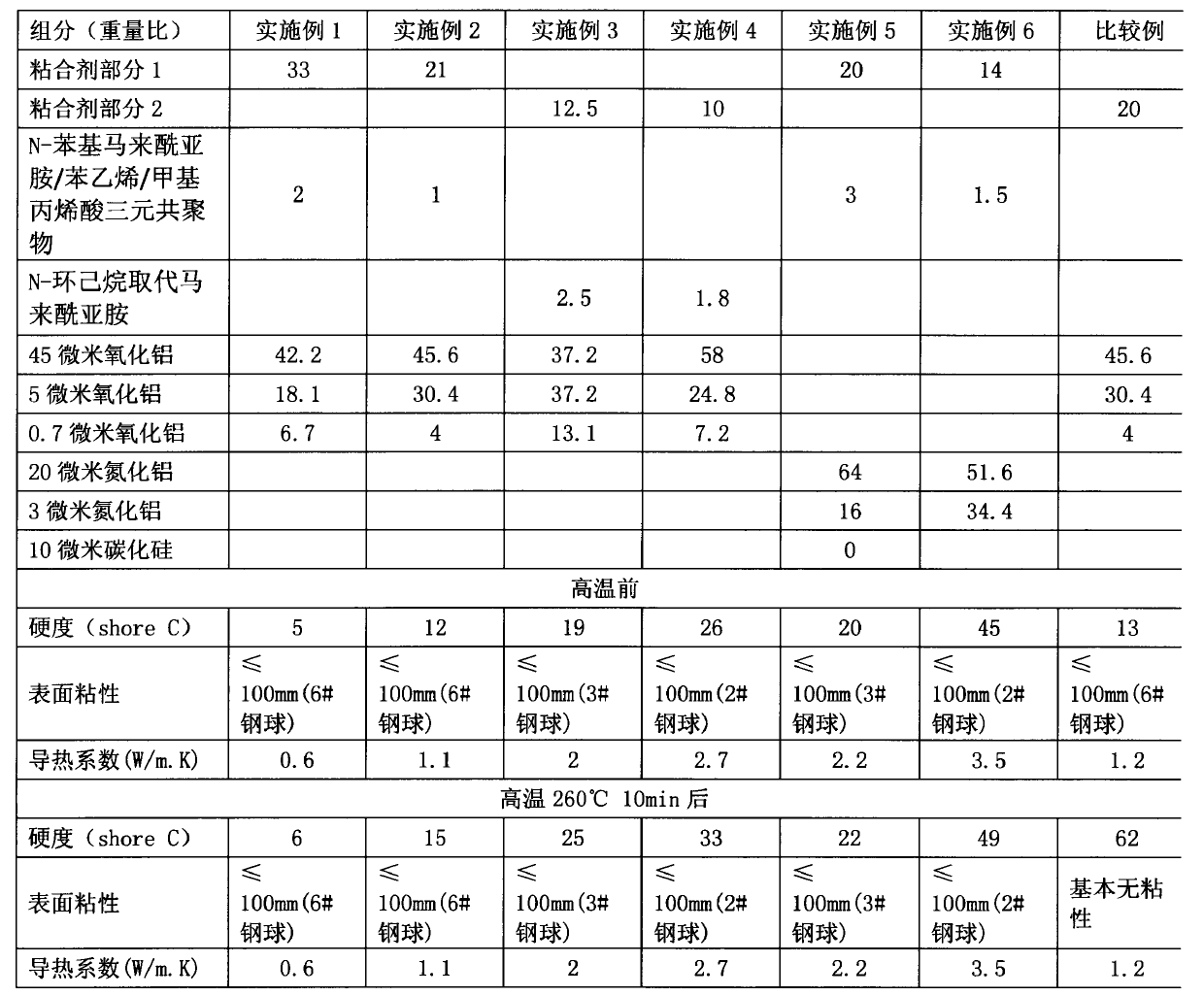

Examples

Embodiment Construction

[0040] Prepolymer preparation: add a certain part of 2-hydroxy-2-methyl-1-phenyl-1-propanone to 100 parts of 2-ethylhexyl acrylate monomer or 2-ethylhexyl methacrylate 1. A certain portion of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide is stirred and irradiated under a 16-20W ultraviolet curing lamp, and the ultraviolet curing lamp is removed after 3-10 minutes. A prepolymer with a viscosity of 3000-5500 cps was obtained. Or add a certain amount of lauroyl peroxide to 100 parts of 2-ethylhexyl acrylate monomer or 2-ethylhexyl methacrylate, stir in an oil bath at 100°C for 5-15 minutes, remove the oil bath, A prepolymer with a viscosity of 2000-5000 cps can be obtained.

[0041] Preparation of adhesive: add 0.05 to 1 part of a monomer with two or more acrylic functional groups to 100 parts of the prepolymer, and then add 0.2 to 0.5 part of a free radical initiator. It can be obtained by stirring at a temperature of ℃ and dissolving.

[0042] Fill the prepared 8-33 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com