Method for constructing light gauge welding residual stress field on basis of small-hole process tested data

A technology of residual stress and test data, which is applied in the field of thin plate welding residual stress field based on small hole method test data, can solve the problems of large amount of calculation in the process of structural stress, low accuracy of test data, and large amount of test data, etc., to reduce calculation Quantity, convenient operation, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

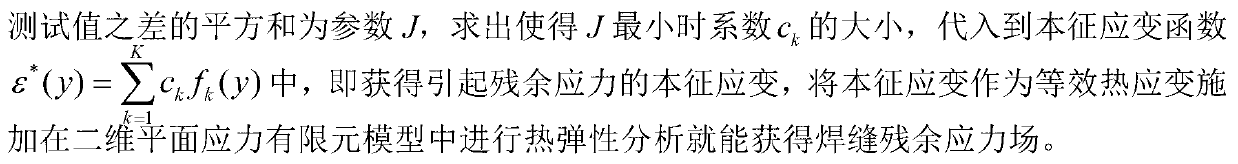

[0031] The present invention will be further explained below in conjunction with the drawings.

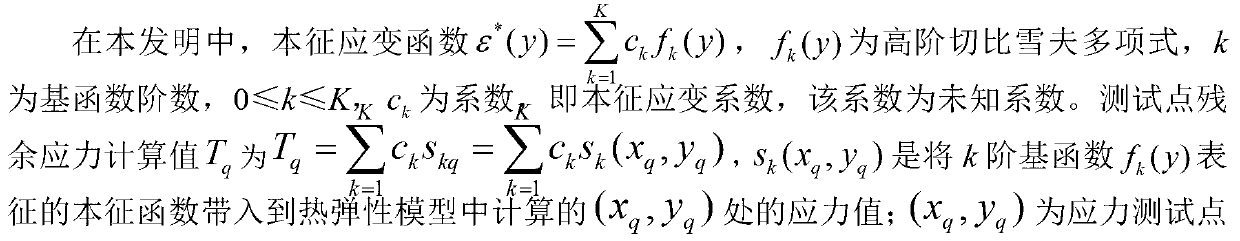

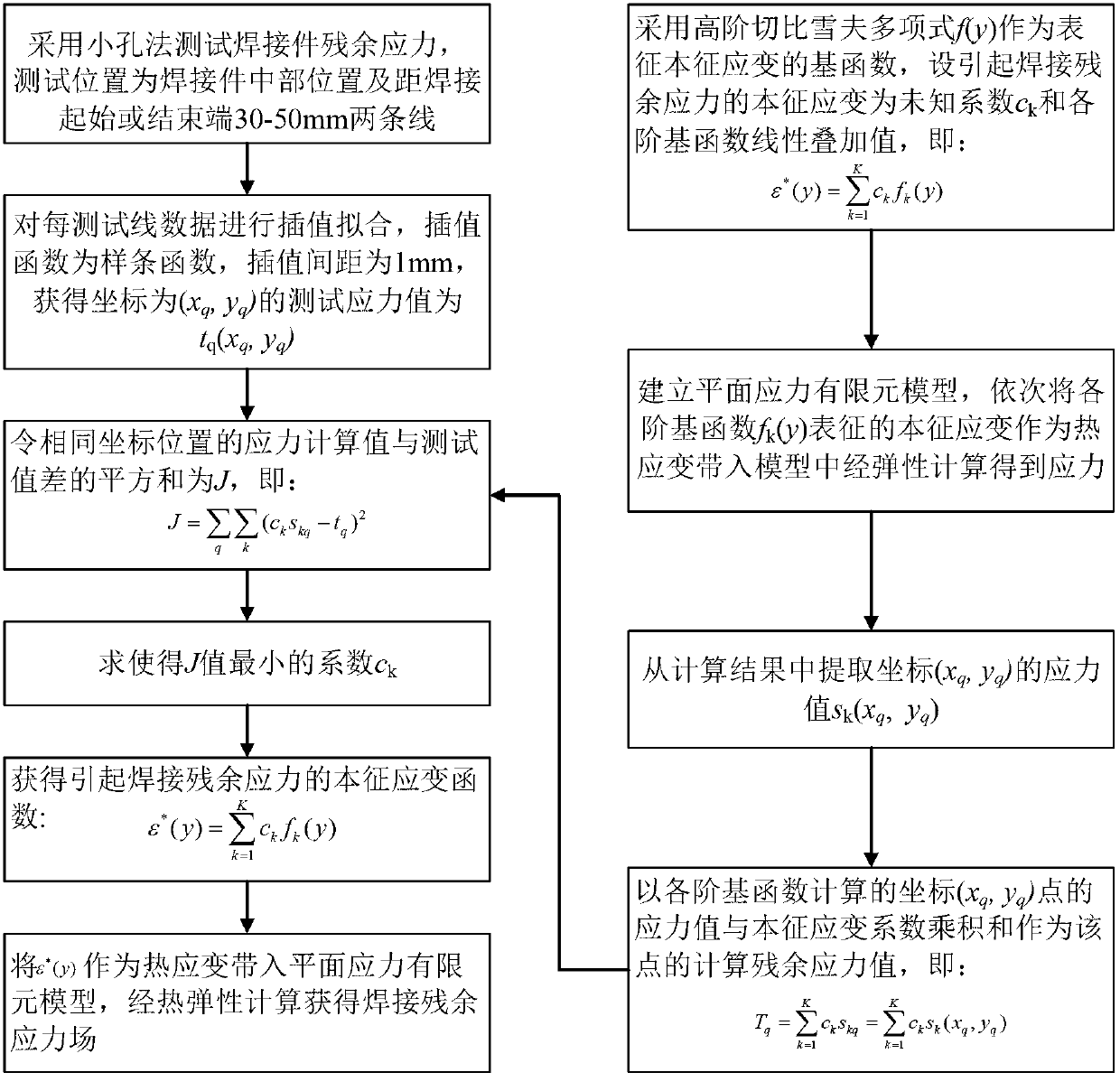

[0032] Such as figure 1 As shown, a method for constructing a thin plate welding residual stress field based on the test data of the small hole method includes the following steps:

[0033] (1) The small hole method is used to test the welding residual stress. The test position for the small hole method to test the welding residual stress is the middle position of the weldment and the position 30-50mm from the welding start or end, such as 35mm from the welding start or end. 40mm, 45mm, etc.; the measured point at each test position is required to reflect the stress change trend on a line perpendicular to the weld direction. The number of test points at each position is 5-15, for example, the number of test points can be 8, 10 , 12, etc.; perform interpolation fitting on the test data, the fitting function is a spline function, and the interpolation interval is 1mm;

[0034] (2) The high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com