High-temperature and low-pressure oxygen dissociation environment test device for heat protection material

A technology of thermal protection material and test device, applied in the direction of analysis materials, instruments, etc., can solve the problems of low reliability, small adjustable range, and many interference factors of flow field reconstruction, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

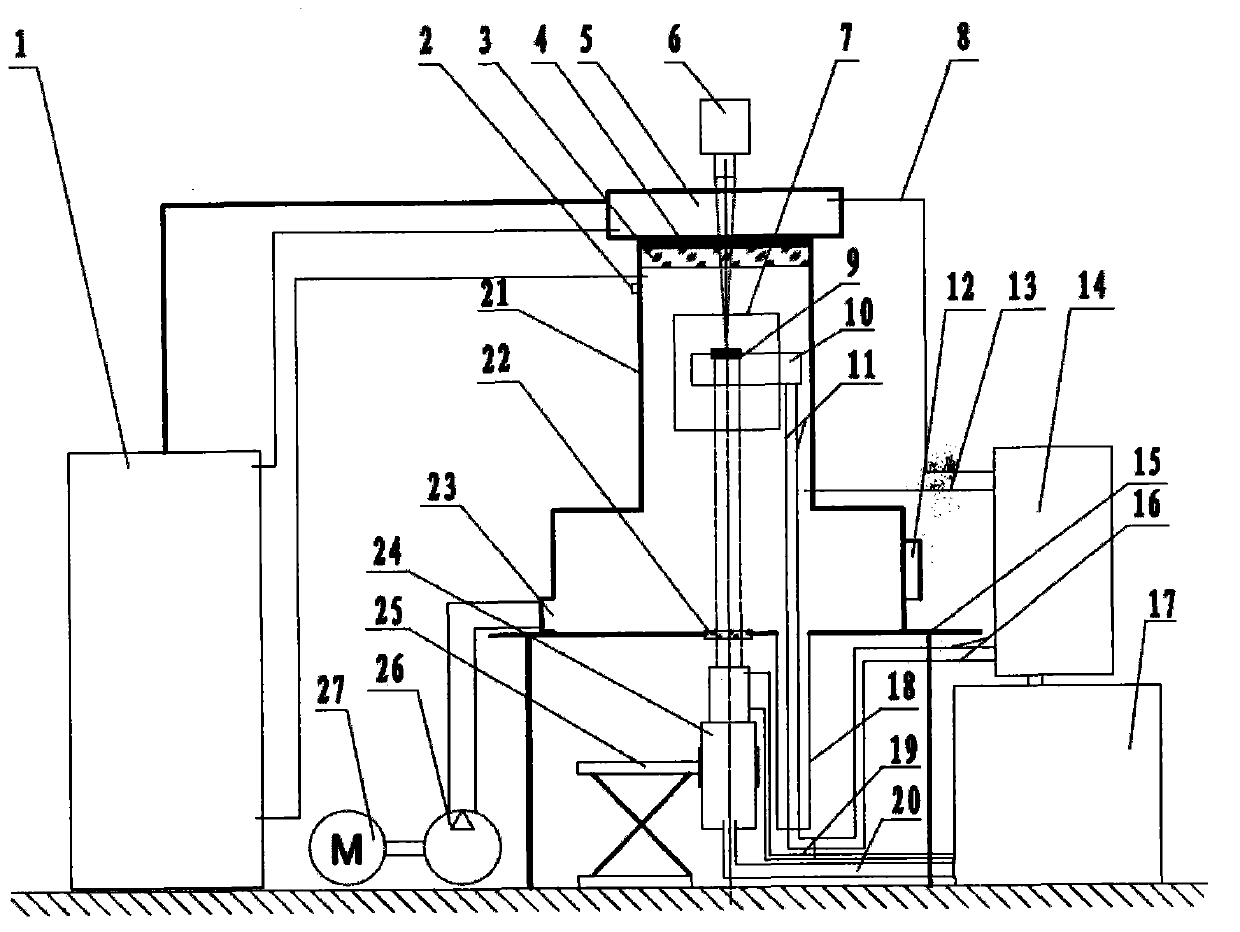

[0018] A high-temperature and low-pressure dissociated oxygen environment test device for thermal protection materials, including an optical platform 15, an environmental chamber 21, a radio frequency power supply 1, a matching box 5, a refrigerator 14, and a laser heater 17, wherein the environmental chamber 21 is placed on the optical platform 15, the RF power supply 1 is output to the flat coil 4 in the matching box 2, and the working gas entering the environmental chamber 21 from the intake flange 2 is discharged through the flat coil 4 to form a dissociated oxygen environment. The sample 9 is placed in a water-cooled bracket 10, the water-cooling bracket 10 is placed on the water-cooling bracket 11, the water-cooling bracket 11 is placed in the vacuum Z-axis translation stage 18, and the vacuum Z-axis translation platform 18 is placed in the environmental chamber 21, and the top of the environmental chamber 21 has a high-transmittance quartz window 3. A heating window 22 i...

Embodiment 2

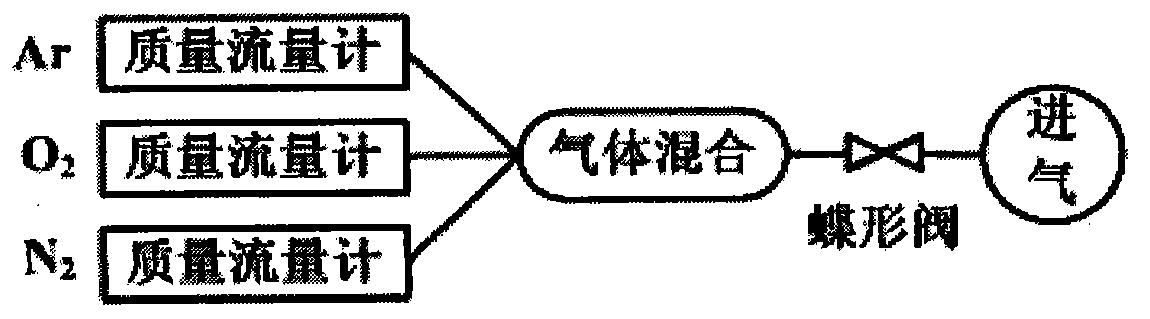

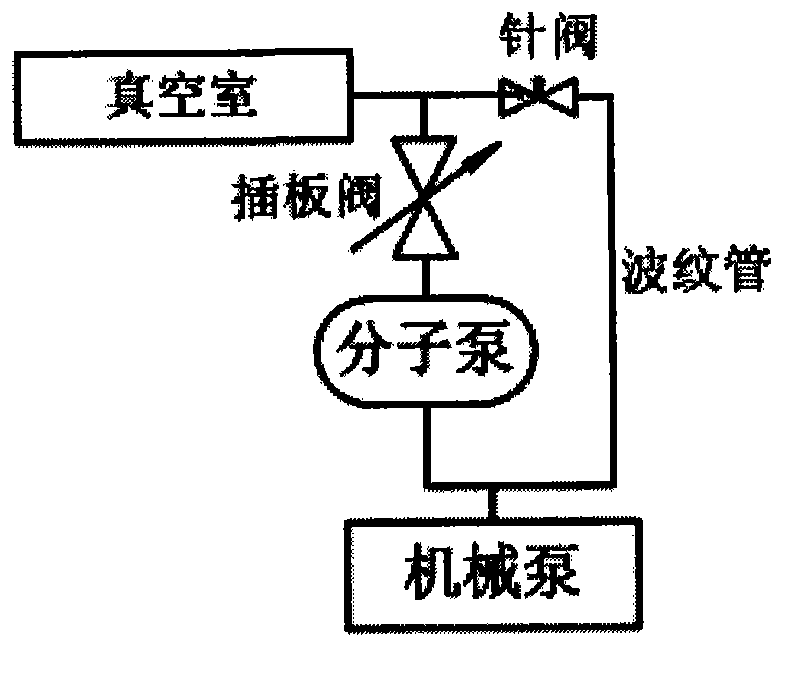

[0020] 1. The dissociated oxygen environment generation subsystem includes a radio frequency power supply, a matching box and an environmental chamber. The environmental chamber is welded by stainless steel, and a reverse flow tank is installed inside to pass cooling circulating water. The upper part is equipped with a high-transmittance quartz window, and the side air inlet and 3 Mass flowmeter, flowmeter control panel, gas pipeline, gas shut-off valve, shut-off valve, pressure reducing valve and gas cylinder are connected, there is a sampling window at the bottom of the side, and the bottom exhaust hole is connected with vacuum valve, solenoid valve, vacuum bellows and vacuum pump , through computer control valves and solenoid valves to adjust the vacuum degree in the environmental chamber, using resistance gauges and ionization gauges for real-time monitoring;

[0021] 2. The laser heating subsystem includes a high-power laser heater, and the laser energy is coupled into the...

Embodiment 3

[0035] This embodiment can test the dissociated oxygen oxidation behavior of thermal protection materials. First, place the sample 9 on the water-cooled bracket 10 and adjust the height of the water-cooled bracket 11 by controlling the vacuum Z-axis 18 to determine the position of the sample 9 in the environmental chamber 21. , close the sampling window 12;

[0036] Turn on the cooling cycle subsystem: check the connection of the four cooling water pipes. The first pipe enters the matching box 5 through the cooling water inlet pipe 8, flows through the RF power supply 1, and the environmental chamber 21, and enters the refrigerator 14 through the cooling water return pipe 13 The second way connects the cooling bracket 10 and the cooling bracket 11 through the cooling circulating water pipe 16, which is used to cool the bracket to prevent the stainless steel bracket from burning out; the third way connects the laser adjustment lens 24 through the cooling circulating water pipe 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com