Pyroelectric thin film infrared focal plane detector chip and manufacturing method thereof

A detector chip and infrared focal plane technology, applied in the field of infrared detection, can solve the problems of airgel thermal conductivity, high surface roughness, difficult operation and control, etc., to reduce thermal conductivity, improve sensitivity, Improved stability and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

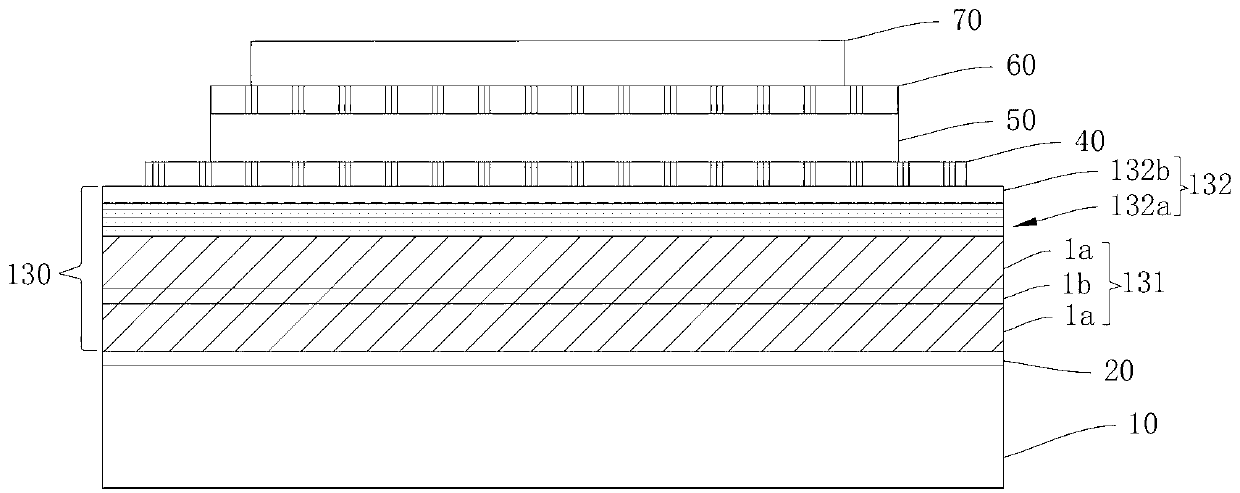

[0063] Such as figure 1 As shown, the pyroelectric thin film infrared focal plane detector chip of the present embodiment comprises a substrate 10, an adhesive layer 20, a heat insulating support structure 130, a lower electrode 40, a photosensitive element 50, an upper electrode 60, and an infrared sensor from bottom to top. Absorbent layer 70. Wherein, the heat insulation support structure 130 includes from bottom to top: a heat insulation layer 131 and a transition support layer 132 .

[0064] In this embodiment, the heat insulating layer 131 includes SiO stacked alternately up and down. 2 Nanoarray 1a and TiO 2 Nanoarray 1b. Specifically, SiO is sequentially deposited from bottom to top in a direction away from the substrate 10 2 Nanoarray 1a, TiO 2 Nanoarray 1b and SiO 2 Nanoarray 1a. Among them, SiO 2 Nanoarray 1a, TiO 2 The nanoarray 1b consists of corresponding SiO 2 Nanostructural unit, TiO 2 Nanostructural unit (not shown in the figure) composition. SiO i...

Embodiment 2

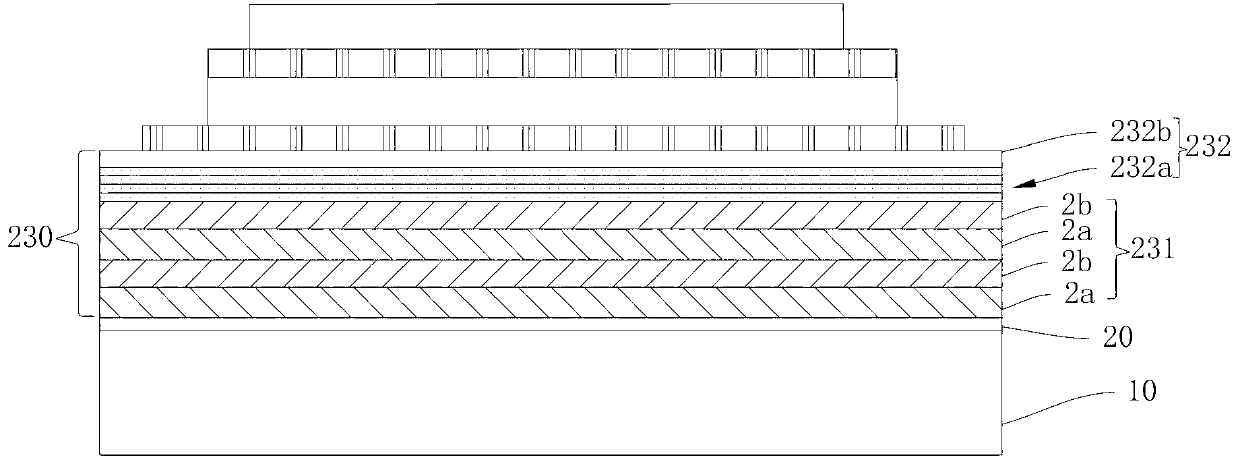

[0086] The difference between this embodiment and embodiment 1 lies in the adhesive layer and the heat insulating support structure. Such as figure 2 As shown, the heat insulating layer 231 of this embodiment includes sequentially depositing SiO from bottom to top in the direction away from the substrate 10 2 Nanoarray 2a, TiO 2 Nanoarray 2b, SiO 2 Nanoarray 2a and TiO 2 nanoarray 2b; and SiO 2 Nanoarrays, TiO 2 The tilt direction of the nanoarrays is opposite, making the SiO 2 Nanoarray TiO 2 The nano-arrays are arranged in a "zigzag" shape. Composition of SiO 2 Nanoarrays, TiO 2 The nano-units of the nano-array are all in the shape of oblique rods.

[0087] The deposition steps of the adhesive layer 20 in this embodiment are as follows: using an electron beam deposition method, controlling the deposition angle to 0°, and depositing a layer of 20 nm thick HfO on the Si substrate 10 at a deposition rate of 0.2 nm / s. 2 as the adhesive layer 20.

[0088] The prepara...

Embodiment 3

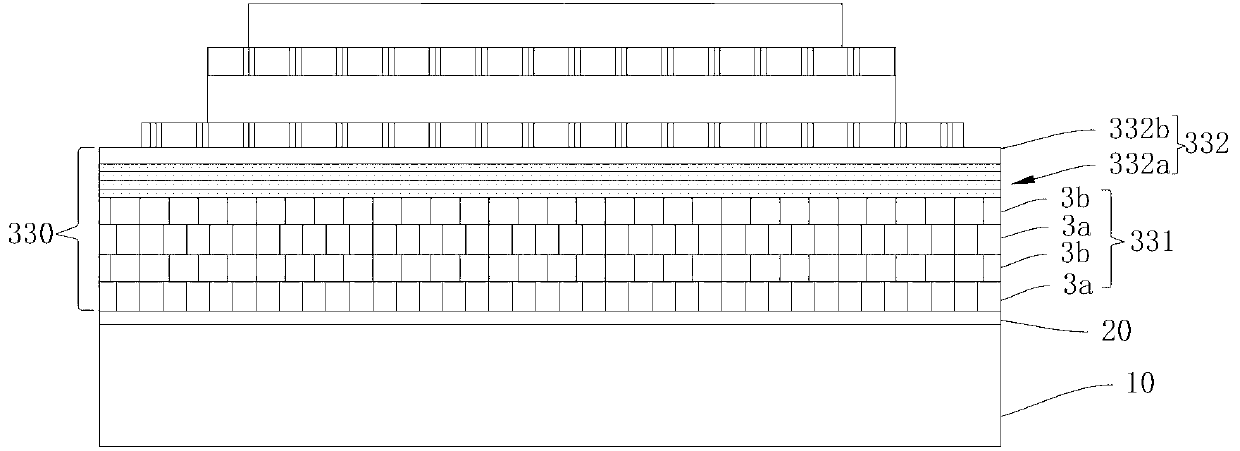

[0095] The difference between this embodiment and embodiment 1 lies in the adhesive layer and the heat insulating support structure. Such as image 3 As shown, the heat insulating layer 331 of this embodiment includes sequentially depositing SiO from bottom to top in the direction away from the substrate. 2 Nanoarray 3a, TiO 2 Nanoarray 3b, SiO 2 Nanoarray 3a and TiO 2 nanoarray 3b; and SiO 2 Nanoarrays, TiO 2 The nano-arrays are arranged in columns and are perpendicular to the surface of the substrate.

[0096] The deposition steps of the adhesive layer 20 in this embodiment are as follows: using an electron beam deposition method, controlling a deposition angle of 0°, and a deposition rate of 0.2 nm / s, depositing a layer of SiO with a thickness of 50 nm on the Si substrate 10. 2 as the adhesive layer 20.

[0097] The preparation method of the thermal insulation layer 331 of the present embodiment is as follows:

[0098](i) Adjust the deposition angle to 86°, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com