Frequency multiplier based on micromachine indirect thermoelectric type power sensor and manufacturing method

A power sensor, thermoelectric technology, applied in the direction of power oscillators, electrical components, etc., can solve the problems of large size, complex circuit structure, etc., and achieve the effect of easy integration, high precision, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further explained below in conjunction with the accompanying drawings.

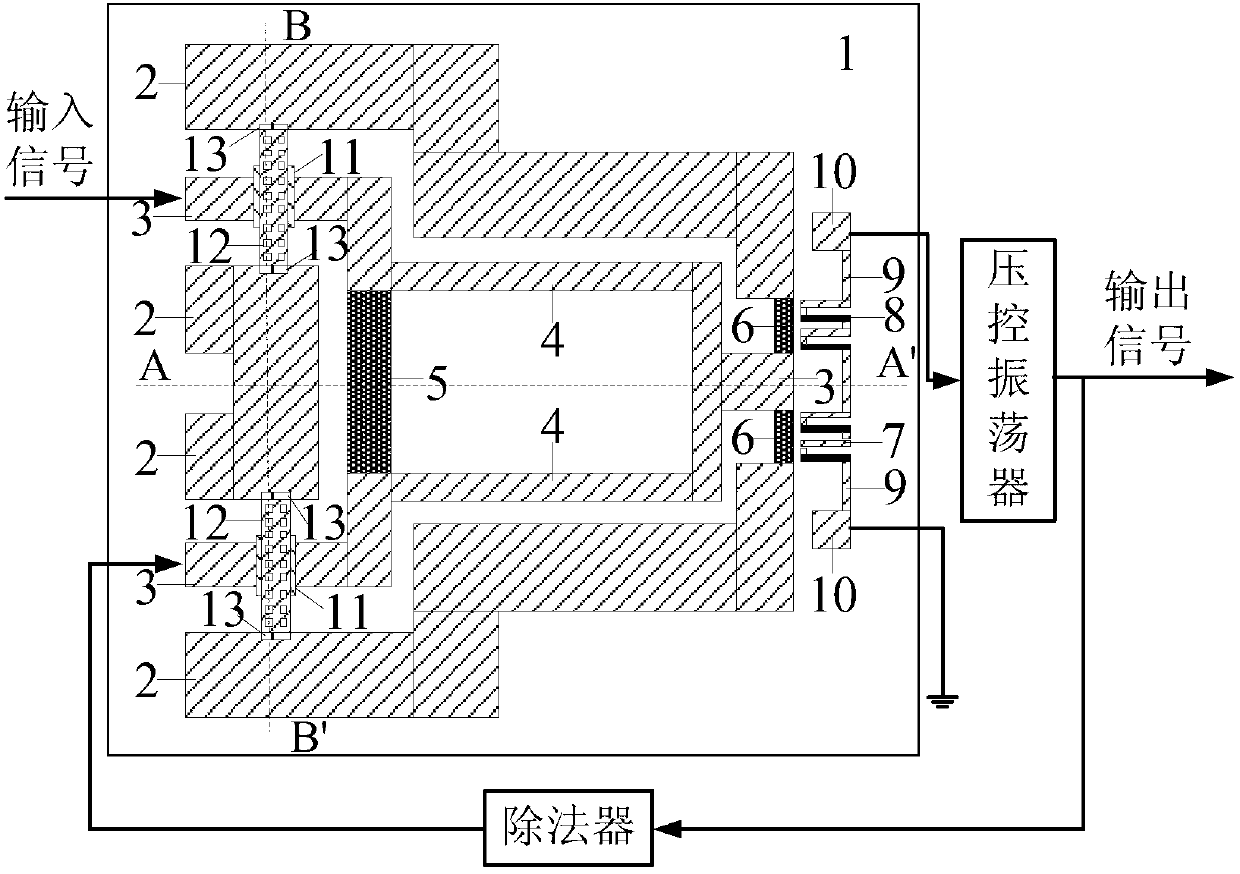

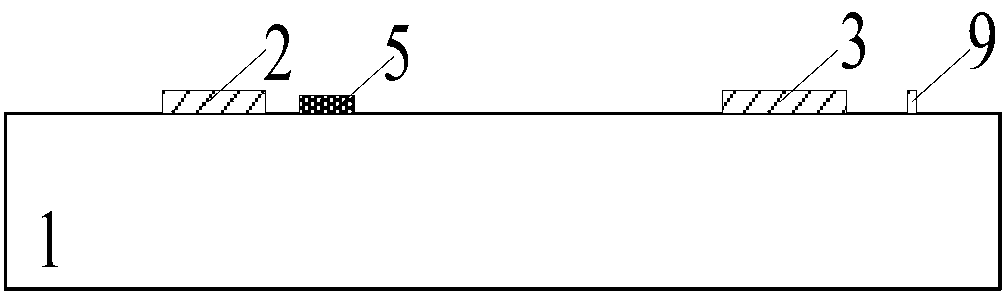

[0043] Such as figure 1 As shown, a frequency multiplier based on a micromechanical indirect thermoelectric power sensor proposed by the present invention includes a substrate 1 made of gallium arsenide (GaAs), a power combiner arranged on the substrate 1, and a MEMS indirect type microwave power sensor, and an external voltage-controlled oscillator and divider, define a symmetry axis on the substrate 1, such as figure 2 shown.

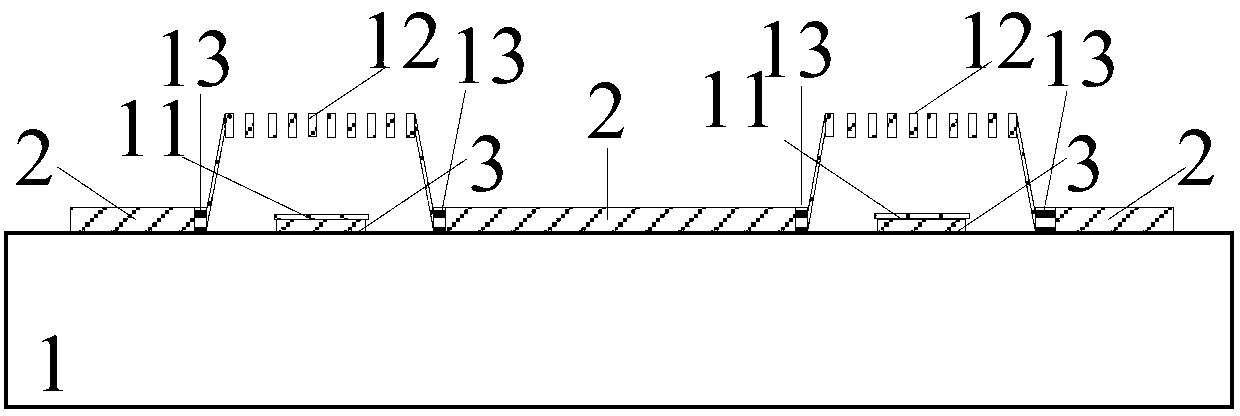

[0044] The power combiner forms a symmetrical structure along the axis of symmetry, including ground wire 2, coplanar waveguide transmission line 3, two sections of asymmetric coplanar stripline 4, isolation resistor 5, two sets of fixed support beams 12 and anchor area 13; the power combiner The function of is to vector synthesize the reference signal and the signal output by the divider (÷N) feedback loop. There is a phase difference bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com