Popping candy producing equipment

A production equipment and popping candy technology, which is applied in confectionery, confectionary industry, food science, etc., can solve problems such as poor cooling effect, low puffing efficiency, and insufficient pressure, so as to improve production efficiency, improve syrup quality, and avoid blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

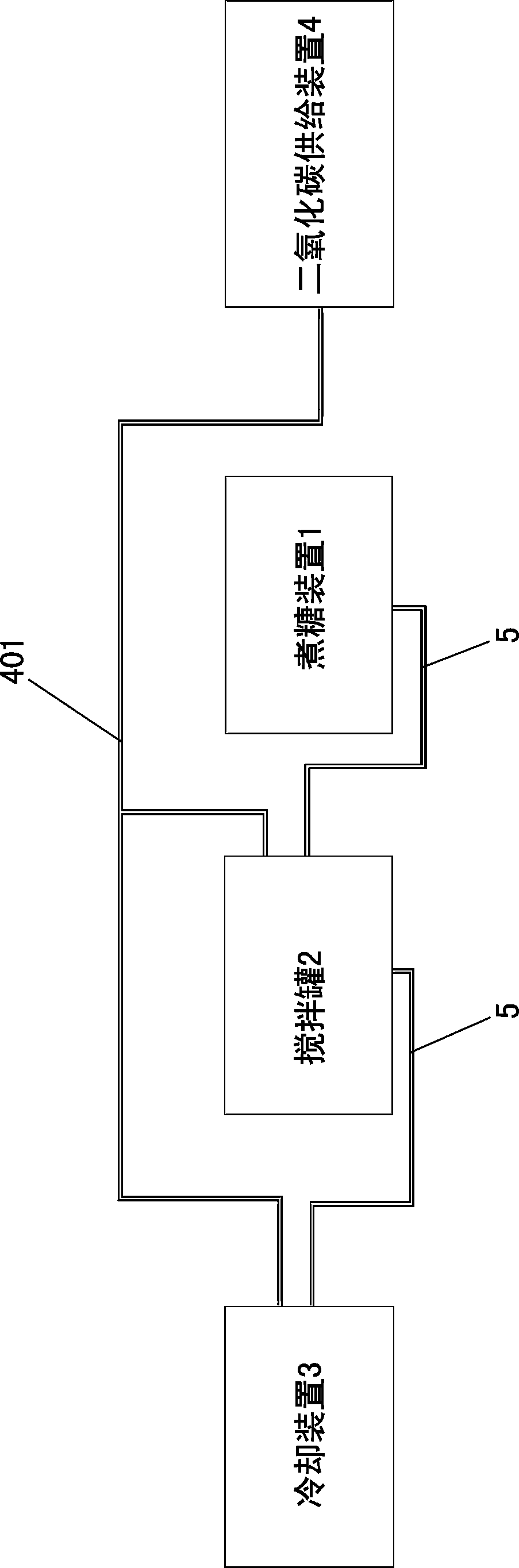

[0041] like figure 1 As shown, this kind of popping candy production equipment includes a sugar cooking device 1, a stirring tank 2 and a cooling device 3 arranged in sequence, and a carbon dioxide supply device 4 connected with the stirring tank 2 and the cooling device 3.

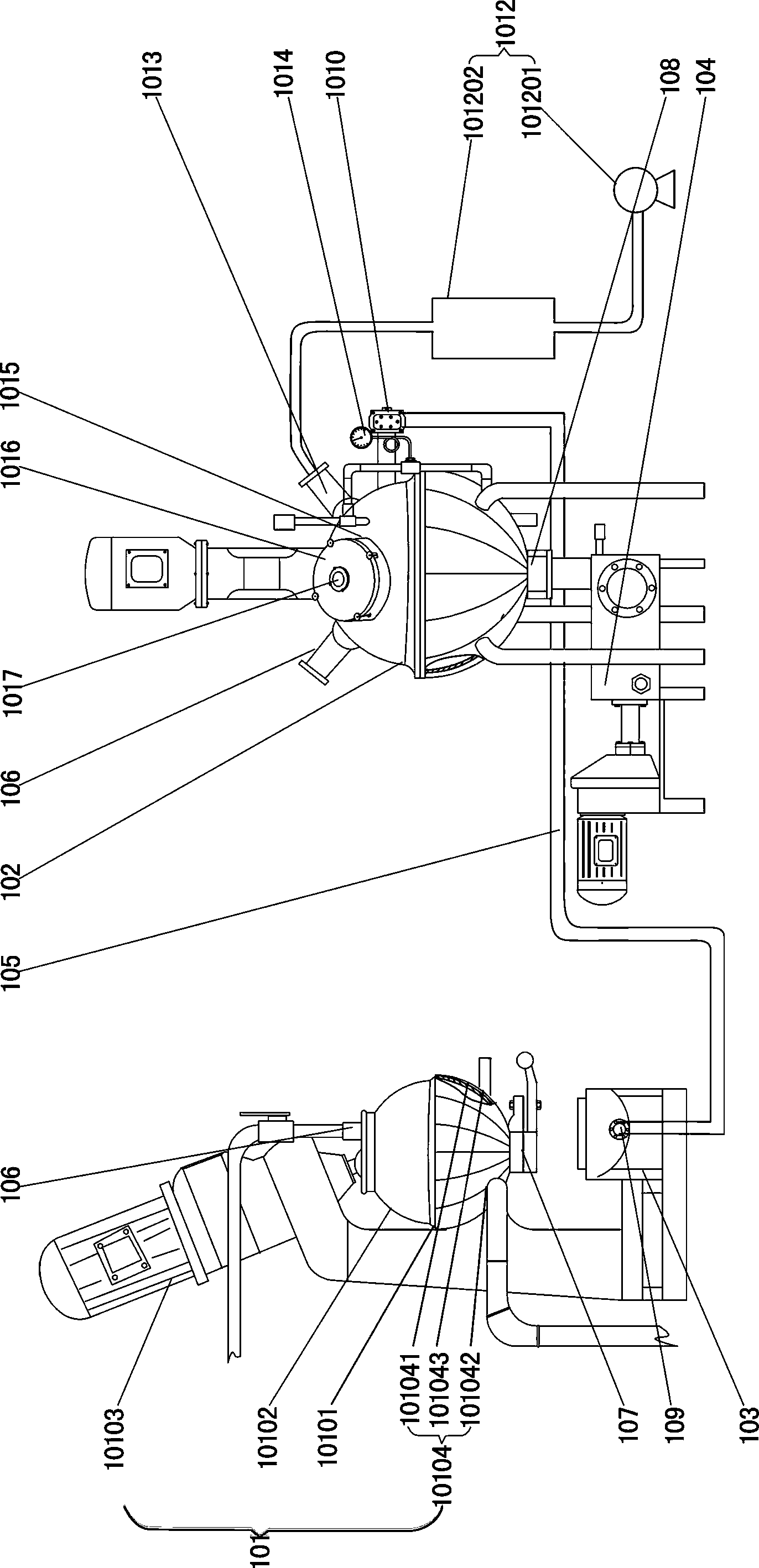

[0042] like figure 2 As shown, the sugar cooking device 1 includes a sugar melting pot 101, a sugar boiling pot 102, a storage barrel 103, a syrup extraction device 104 (usually a pump) and a sugar feeding pipe 105. The bottom of the sugar melting pot 101 is provided with a discharge valve 107, The storage barrel 103 is arranged below the discharge valve 107, the bottom of the sugar cooking pot 102 is provided with a syrup outlet 108, the syrup extraction device 104 is connected with the syrup outlet 108, the storage barrel 103 is provided with a sugar outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com