Green silicon carbide reaction mixture and synthetic technology and charging baffle plate finished by adopting same

A green silicon carbide and mixed material technology, applied in the direction of silicon carbide, carbide, etc., can solve the problems of silicon carbide quality decline, production cost increase, etc., achieve the effect of increasing material density, reducing operating time, and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

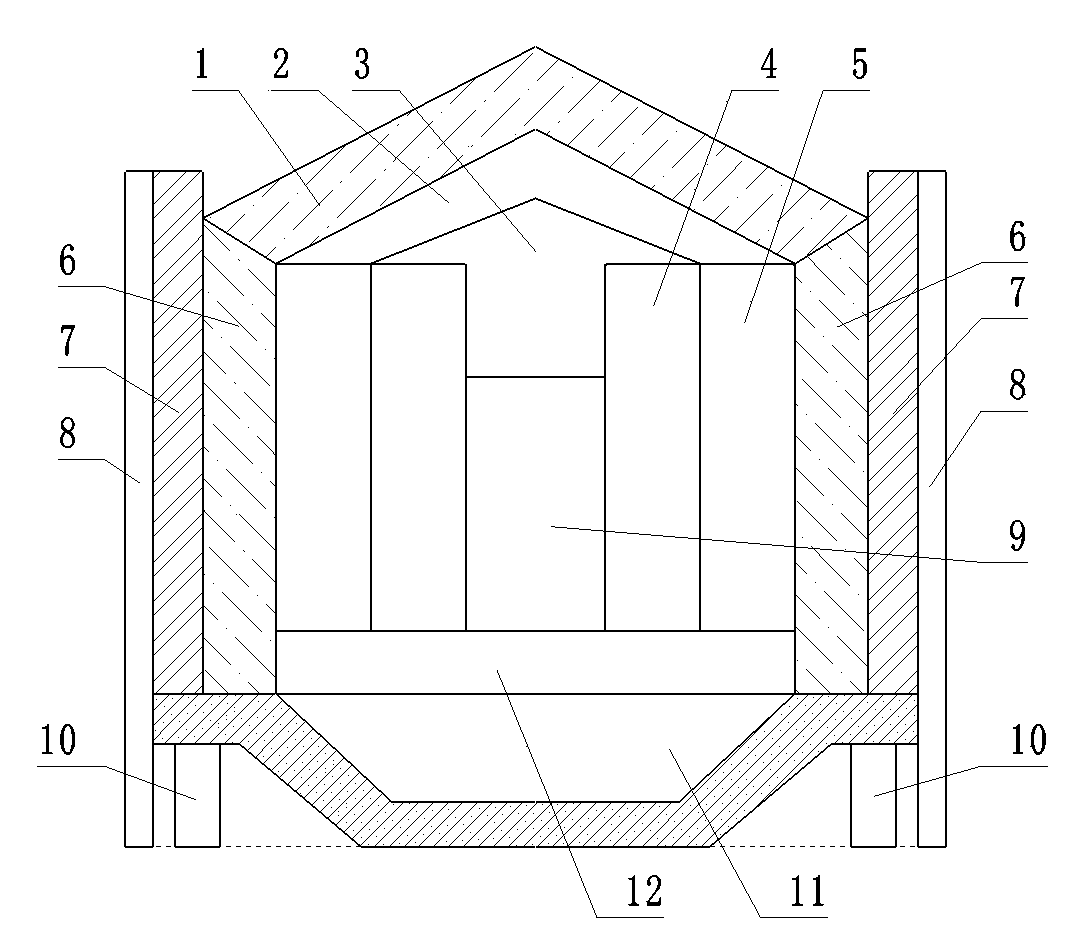

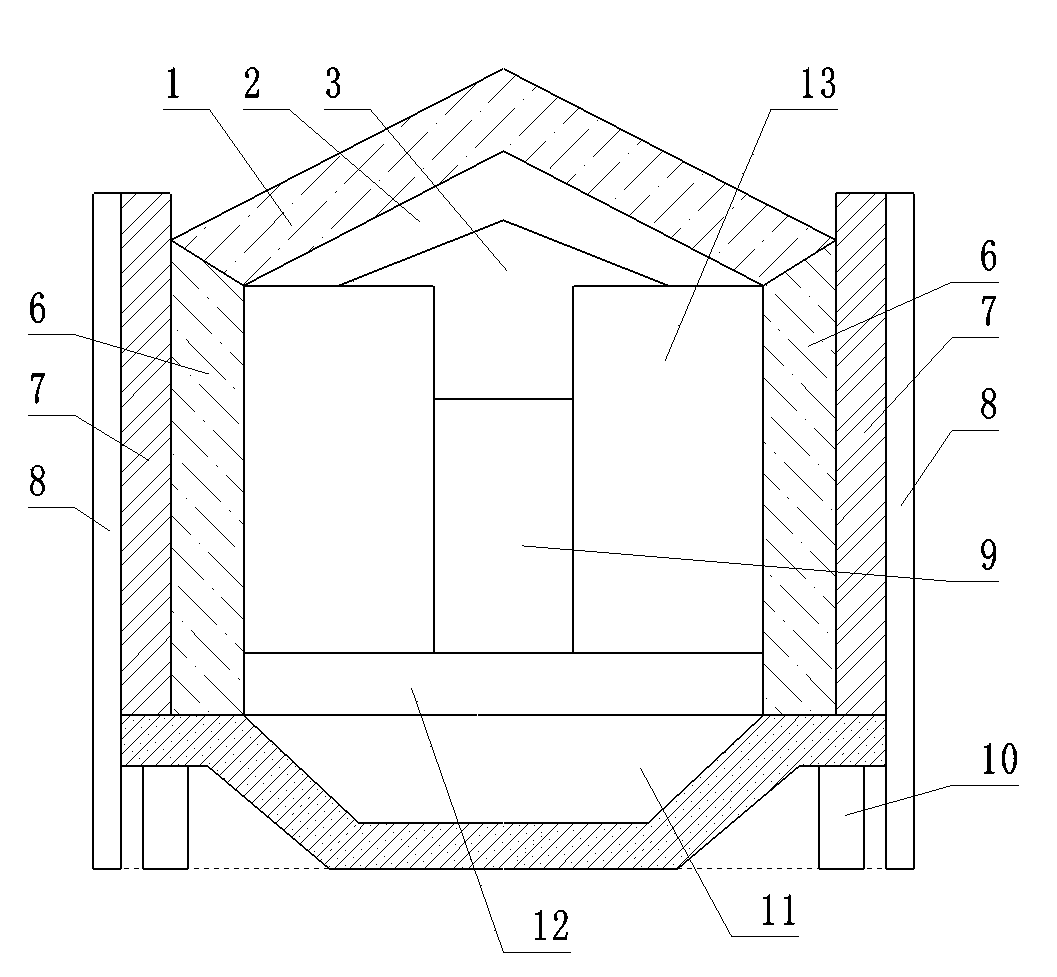

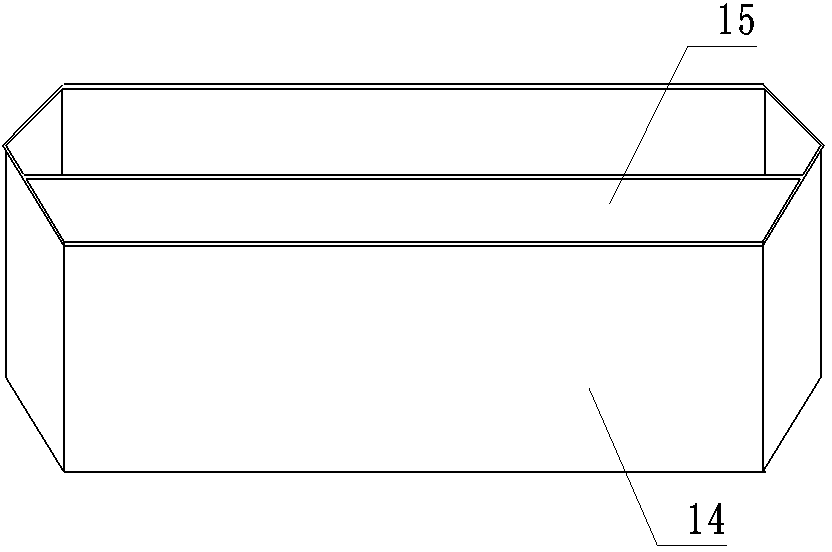

[0046] refer to figure 1 — Figure 4 , a kind of green silicon carbide reactive mixture, comprising the following materials by weight:

[0047] Add 0.2 parts by weight of quartz sand, 0.18 parts of petroleum coke, 0.2 parts of silicon carbide return charge, and 0.5 parts of fine crystals to 1 part by weight of roasting material;

[0048] The SiO of the quartz sand 2 Content≥99.3%, Al 2 o 3 Content≤0.3%, Fe 2 o 3 Content ≤ 0.2%, CaO content ≤ 0.1%, Ignition content ≤ 0.2%;

[0049] The fixed carbon of the petroleum coke is ≥ 90%, the ash content is ≤ 0.8%, the volatile content is ≤ 7%, and the sulfur content is ≤ 1%;

[0050] The calcined material is obtained after the front round green silicon carbide synthesis reaction, wherein the Sic content is 20%, SiO 2 Content 25%, Al 2 o 3 content 2%, MgO content 0.03%, CaO content 0.6%, Fe 2 o 3 Content 0.05%, F·C content 5%, NaCl content 0.1%;

[0051] The SiO of the silicon carbide return charge 2 Content ≥ 90%, F·C c...

Embodiment 2

[0057] Compared with Example 1, the difference of this example is: a kind of green silicon carbide reactive mixture, comprising the following materials by weight:

[0058] Add 0.3 parts by weight of quartz sand, 0.45 parts of petroleum coke, 0.3 parts of silicon carbide return charge, and 0.3 parts of fine crystals to 1 part by weight of the calcined material;

[0059] Wherein said calcined material is obtained after the synthetic reaction of front wheel green silicon carbide, wherein the Sic content is 22%, SiO 2 Content 28%, Al 2 o 3 content 3%, MgO content 0.02%, CaO content 0.5%, Fe 2 o 3 Content 0.08%, F·C content 2%, NaCl content 0.2%.

Embodiment 3

[0061] Compared with Example 1, the difference of this example is: a kind of green silicon carbide reactive mixture, comprising the following materials by weight:

[0062] Add 0.4 parts by weight of quartz sand, 0.22 parts of petroleum coke, 0.1 part of silicon carbide return charge, and 0.4 parts of fine crystals to 1 part by weight of the calcined material;

[0063] Wherein said calcined material is obtained after the synthetic reaction of front wheel green silicon carbide, wherein the Sic content is 24%, SiO 2 Content 30%, Al 2 o 3 content 4%, MgO content 0.01%, CaO content 0.3%, Fe 2 o 3 Content 0.14%, F·C content 4%, NaCl content 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com