Method for extraction and preparation of alumina from coal ash

A technology of alumina and coal ash, which is applied to the removal of alumina/hydroxide and solid waste to achieve the effects of reducing pollution, realizing high value-added utilization, and reducing the amount of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, typical but non-restrictive embodiment of the present invention is as follows:

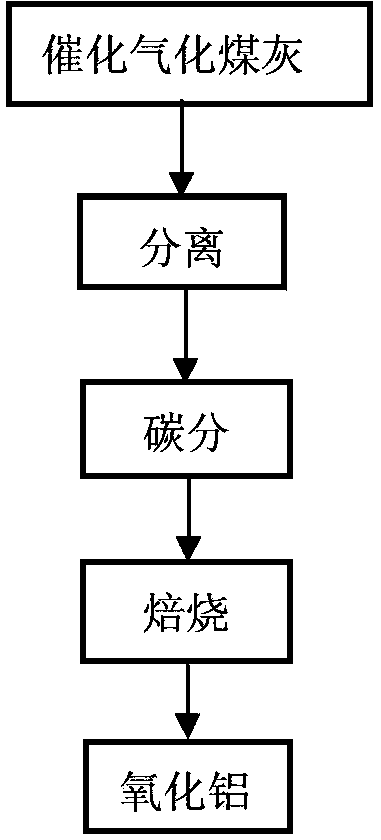

[0033] Such as figure 1 As shown, in a typical embodiment of the present invention, a method for extracting and preparing alumina from coal ash containing a catalyst, the method comprising:

[0034] (a) separation of catalysts and aluminum-containing compounds from coal ash;

[0035] (b) carbonizing the aluminum-containing compound to obtain a catalyst-containing solution and aluminum hydroxide;

[0036] (c) Calcining aluminum hydroxide to obtain alumina.

[0037] The catalyst refers to a catalyst that can produce a catalytic effect on the gasification reaction of coal. The present invention organically combines the catalyst recovery and the process of preparing alumina to improve the overall economics of the coal catalytic gasification process, which is in line with the poly...

specific Embodiment approach 1

[0055] Coal ash produced by catalytic coal gasification is used as raw material, and the catalyst used is potassium carbonate, potassium hydroxide, potassium sulfate, potassium chloride and other alkali metal potassium compounds, preferably potassium carbonate and potassium hydroxide.

[0056] Such as figure 1 As shown, the method for extracting and preparing alumina from coal ash comprises the following steps:

[0057] (1) Separation of catalysts and aluminum-containing compounds from coal ash;

[0058] (2) The above-mentioned aluminum-containing compound is subjected to carbonization at 30-70°C, and the pH value of the carbonization end point is 8-12. After filtration, aluminum hydroxide is obtained. The filtrate can be used as a coal catalytic gasification catalyst or in the leaching step The lye is recycled.

[0059] (3) Roasting: Roast the obtained aluminum hydroxide at a temperature of 1000-1300°C to obtain metallurgical grade alumina.

specific Embodiment approach 2

[0060] Coal ash produced by catalytic coal gasification is used as raw material, and the catalyst used is potassium carbonate, potassium hydroxide, potassium sulfate, potassium chloride and other alkali metal potassium compounds, preferably potassium carbonate and potassium hydroxide.

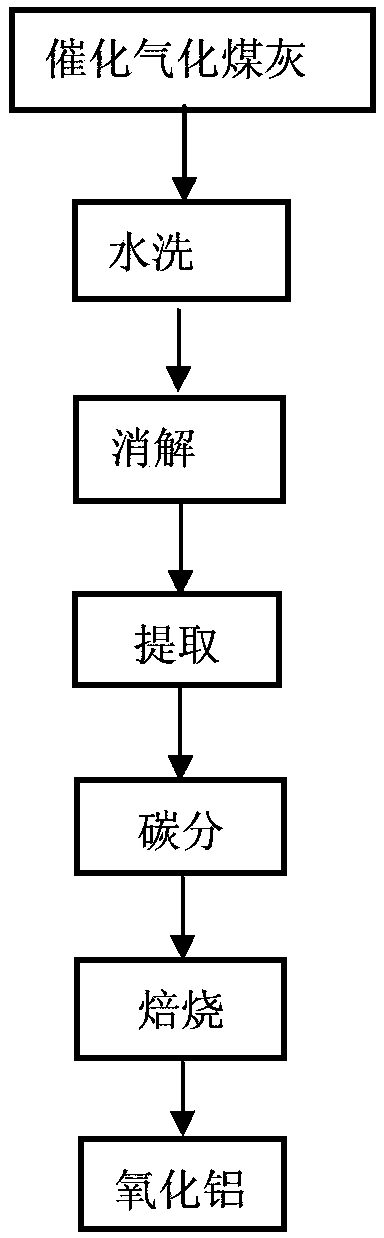

[0061] Such as figure 2 As shown, the method for extracting and preparing alumina from coal ash comprises the following steps:

[0062] (1) Water washing: use high-alumina coal ash containing catalyst potassium and deionized water (tap water, wastewater from the water washing tower in the process of coal catalytic gasification and gasification can also be used) (Water after process waste liquid treatment) is washed with water at a solid-to-liquid ratio of 1:1-6, the number of washings is 1-2 times, the washing temperature is 20-80°C, and the washing time is 10-60 minutes. Solution and washed solid ash;

[0063] (2) Digestion: Mix the washed ash and calcium hydroxide (calcined calcium oxide c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com