2-methyl-4-chlorophenoxyacetic acid preparation technology

A technology of chlorophenoxyacetic acid and sodium chlorophenoxyacetic acid, applied in the field of 2-methyl-4-chlorophenoxyacetic acid preparation technology, can solve problems such as work clothes damage, waste, high flammability, etc., and achieves increased safety, improved The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

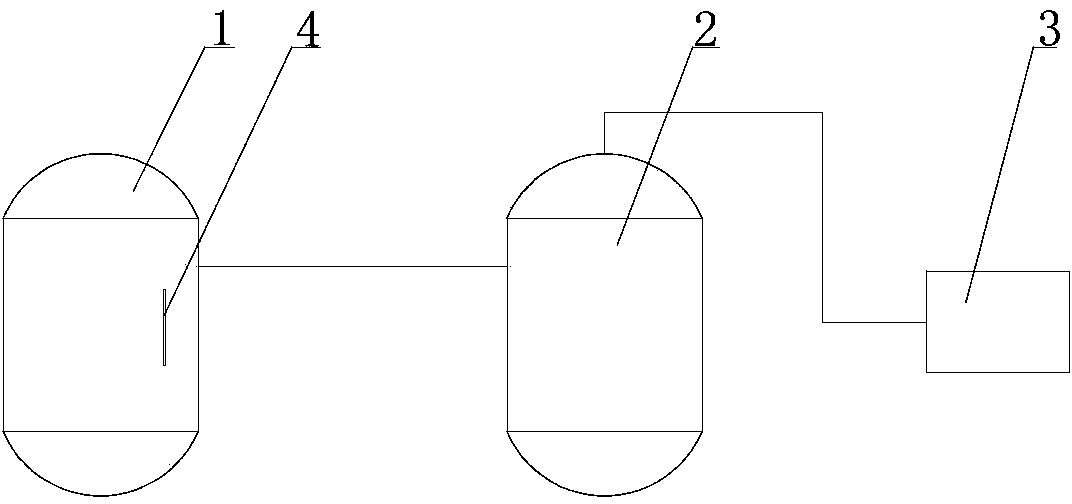

[0022] figure 2 The structural diagram shown mainly includes a condensation reaction kettle 1 , an enamel reaction kettle 2 , an enamel condenser 3 , and a platinum resistance thermometer 4 .

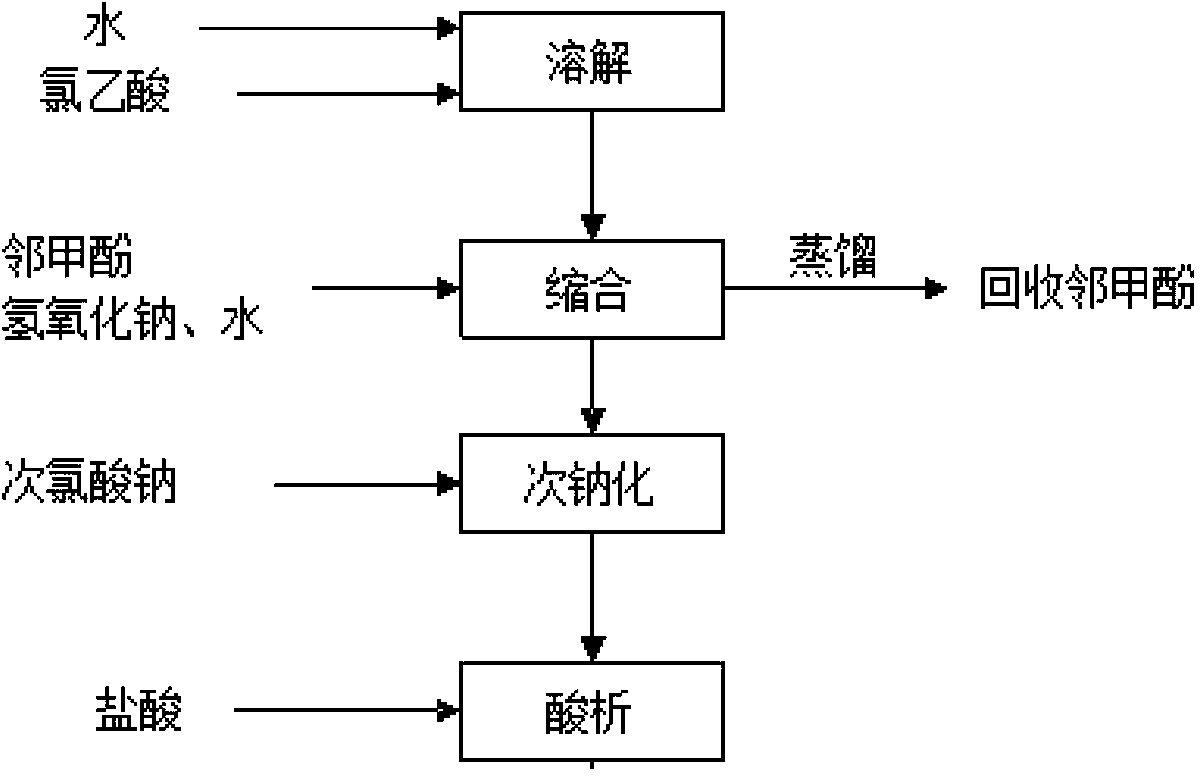

[0023] A kind of 2-methane-4-chlorophenoxyacetic acid preparation technology of the present invention mainly comprises the following steps:

[0024] a. Dissolve chloroacetic acid in water for later use, and the mixing ratio of the two is 1:1.

[0025] b. Place o-cresol and sodium hydroxide in the condensation reactor for deployment, ensuring that the ratio of the two is 5:1, the reaction temperature is 55°C-65°C, the optimal reaction time is 0.4h-0.6h, and finally An aqueous solution of sodium o-cresate was obtained.

[0026] c. After the above reaction in b, drop the chloroacetic acid solution obtained in a to ensure that the ratio of the chloroacetic acid solution to the o-cresol sodium aqueous solution is 1.05:1, the reaction temperature is 110°C-130°C, and the optimum reaction ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com