Phase-change thermal energy-storage material applicable to heat-pump water heater and preparation method thereof

A phase change heat storage material, heat pump water heater technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of crystal deposition, unsuitable for long-term use, instability, etc., and achieve stable performance and phase change latent heat value. The effect of large and small volume expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

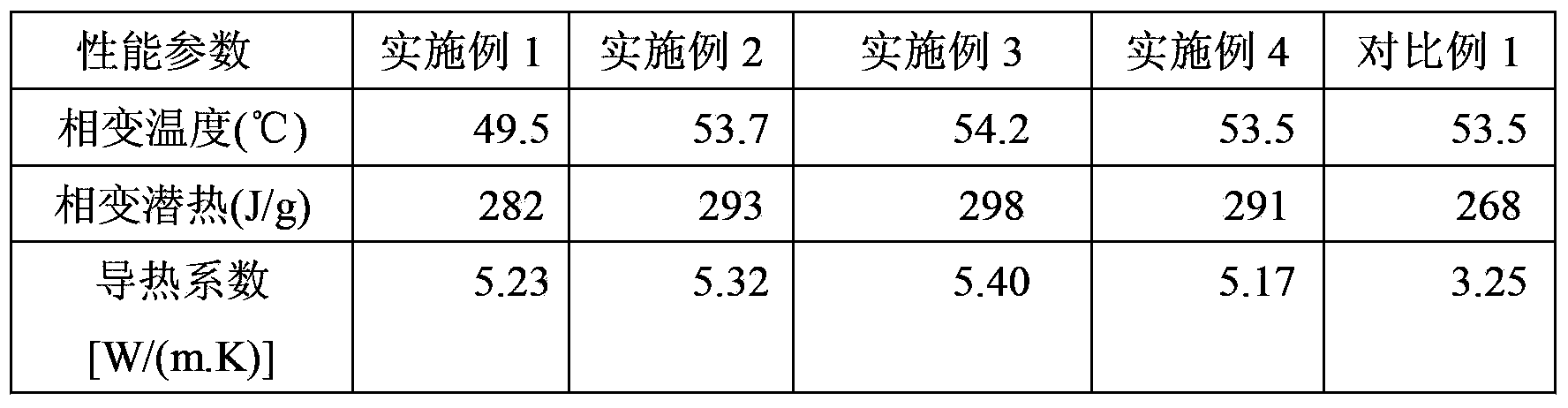

Examples

Embodiment 1

[0029] Example 1: The phase-change heat storage material in this example includes a mixture of the following components and weight ratios: 20 parts of stearic acid, 35 parts of palmitic acid, 15 parts of lauric acid, 20 parts of paraffin, and 4 parts of thermally conductive carbon nanofibers part, the addition of expanded graphite is 15% of the paraffin weight, and the addition of NaCl (sodium chloride) is 5.5% of the total weight of the four components of stearic acid, palmitic acid, lauric acid and paraffin. It is prepared by a sol-gel process, as follows: firstly heat the paraffin, and after it is completely melted, add expanded graphite and mix in proportion to form a mixture of paraffin and expanded graphite; at the same time, stearic acid, palmitic acid and lauric acid are separately Melt, mix according to the proportion to form a eutectic mixture of three components and heat to a completely molten state, then mix with paraffin expanded graphite and add a certain proporti...

Embodiment 2

[0030] Embodiment 2: The phase-change heat storage material in this embodiment includes a mixture of the following components and weight ratios: 25 parts of stearic acid, 30 parts of palmitic acid, 20 parts of lauric acid, 25 parts of paraffin, and 4 parts of heat-conducting carbon nanofibers part, the addition of expanded graphite is 18% of the paraffin weight, and the addition of NaCl is 5% of the total weight of the four components of stearic acid, palmitic acid, lauric acid and paraffin. The preparation method is the same as in Example 1.

Embodiment 3

[0031] Embodiment 3: The phase change heat storage material in this embodiment includes a mixture of the following components and weight ratio: 30 parts of stearic acid, 40 parts of palmitic acid, 10 parts of lauric acid, 22 parts of paraffin, 5 parts of thermally conductive carbon nanofibers part, the addition of expanded graphite is 20% of the paraffin weight, and the addition of NaCl is 6% of the total weight of the four components of stearic acid, palmitic acid, lauric acid and paraffin. The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com