Cutting fluid composition

A technology of composition and cutting fluid, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of poor viscosity stability, abrasive dispersion stability, contamination of workpieces or tools, strict water quality requirements, etc., and achieves stable storage and good penetration. The effect of good permeability and excellent permeability

Active Publication Date: 2015-07-01

安徽中天石化股份有限公司

View PDF4 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these cutting fluids have disadvantages

Oil-based cutting fluid has poor cooling effect at the cutting point

Oil-based cutting fluid will pollute workpieces or tools, which need to be further cleaned with organic solvents, which is not friendly to the environment

Glycol-based cutting fluids and water-based cutting fluids perform poorly in terms of viscosity stability during cutting operations and dispersion stability of abrasives

[0008] At present, the performance and use effect of various water-based cutting fluids vary with different formulations. Compared with emulsions, although they have the advantages of less energy consumption, lower cost, and less pollution, there are still some shortcomings, such as : Some still have certain pollution, some have odor, and some have stricter requirements on the prepared water quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

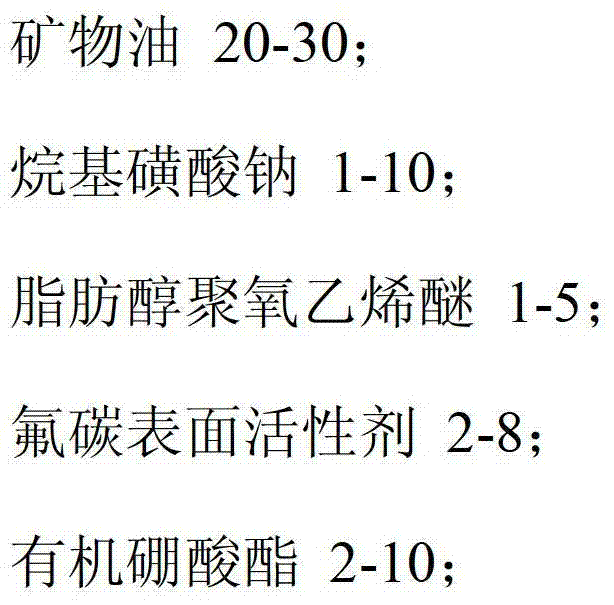

[0024] In this implementation, a cutting fluid composition comprises the following components in parts by weight:

[0025]

[0026]

Embodiment 2

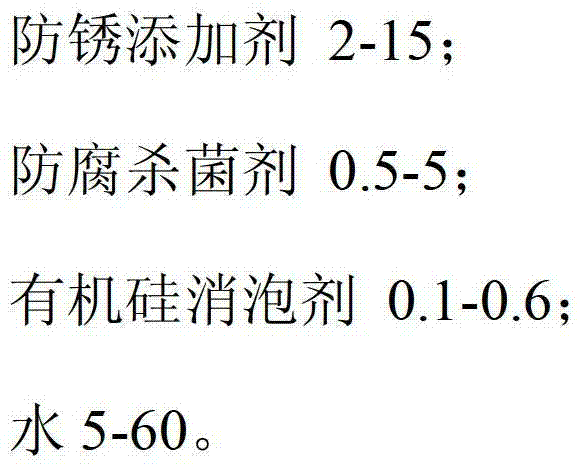

[0028] In this implementation, a cutting fluid composition comprises the following components in parts by weight:

[0029]

Embodiment 3

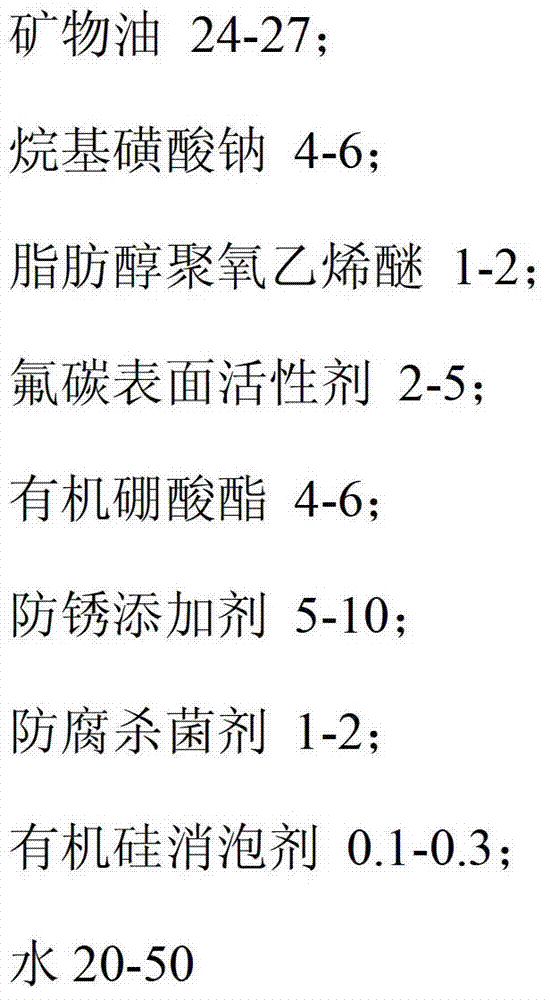

[0031] In this implementation, a cutting fluid composition comprises the following components in parts by weight:

[0032]

[0033]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a cutting fluid composition. The cutting fluid composition comprises, by weight, 20-30 parts of mineral oil, 1-10 parts of alkyl sodium sulfonate, 1-5 parts of fatty alcohol-polyoxyethylene ether, 2-8 parts of fluorocarbon surfactants, 2-10 parts of organic boric acid ester, 2-15 parts of antirust additives, 0.5-5 parts of anticorrosion bactericides, 0.1-0.6 parts of organosilicon antifoaming agents and 5-60 parts of water. The cutting fluid composition is advantaged by good permeability, antirust performance and bacteriostasis anticorrosion performance, storage stabilization and moderate viscosity.

Description

technical field [0001] The invention relates to the technical field of cutting fluids, in particular to a cutting fluid composition. Background technique [0002] Cutting fluid is an industrial liquid used for cooling and lubricating cutting tools and workpieces during metal cutting, chipping and grinding. Excellent cooling performance, lubricating performance, anti-rust performance, degreasing and cleaning function, anti-corrosion function, and easy dilution. [0003] According to the chemical composition of oil, cutting fluid is divided into two categories: non-water-soluble (oil-based) fluid and water-soluble (water-based) fluid. Oil-based cutting fluids have better lubricating properties and poorer cooling effects. Compared with oil-based cutting fluid, water-based cutting fluid has relatively poor lubricating performance and better cooling effect. Slow cutting requires the lubricity of the cutting fluid to be strong. Generally speaking, cutting oil is used when the c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10M173/00C10N40/22

Inventor 林伟江海涛江海波江浩

Owner 安徽中天石化股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com