Energy-saving and environment-friendly displacement cooking process for wood and bamboo raw materials

An energy-saving and environmental-friendly replacement cooking technology, which is applied in fiber raw material processing, cellulose raw material pulping, textile and papermaking, etc., can solve the problems of insufficient recycling of fine fibers, failure to achieve the best environmental effect, waste of fiber resources, etc. , to achieve the effects of less bleaching chemicals, less steam consumption, and less pollution load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

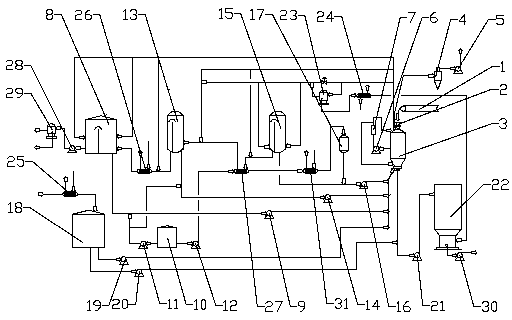

[0054] Embodiments, the present invention generally consists of 3 to 5 cooking pots 3 according to the cooking cycle of the pulp species. The system uses the cooking pots as the core to support a common storage tank, and stores black liquor with different temperatures and different chemical properties to serve the cooking cycle. At the same time, it is also equipped with heat exchangers, heaters, exhaust systems and black liquor filtration equipment, and adopts advanced and reliable automatic control technology to synergistically exert the comprehensive effects of system technology.

[0055] like figure 1 Shown, a wood, bamboo raw material energy-saving environmental protection displacement cooking process, this process comprises the following steps:

[0056] 1. Pot loading operation;

[0057] A. First open the pot cover valve 2 and start the exhaust fan 5, and then start the belt conveyor 1. While loading the pot, heat the wood chips or bamboo chips with low-pressure steam....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com