Optimized design method of reducing sonic system sound insulator of acoustic logging-while-drilling drill collar

A design method and an optimized technology, applied in surveying, earthwork drilling, wellbore/well components, etc., can solve the problems of unfavorable drilling sonic technology promotion and use, high cost, high R&D and processing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

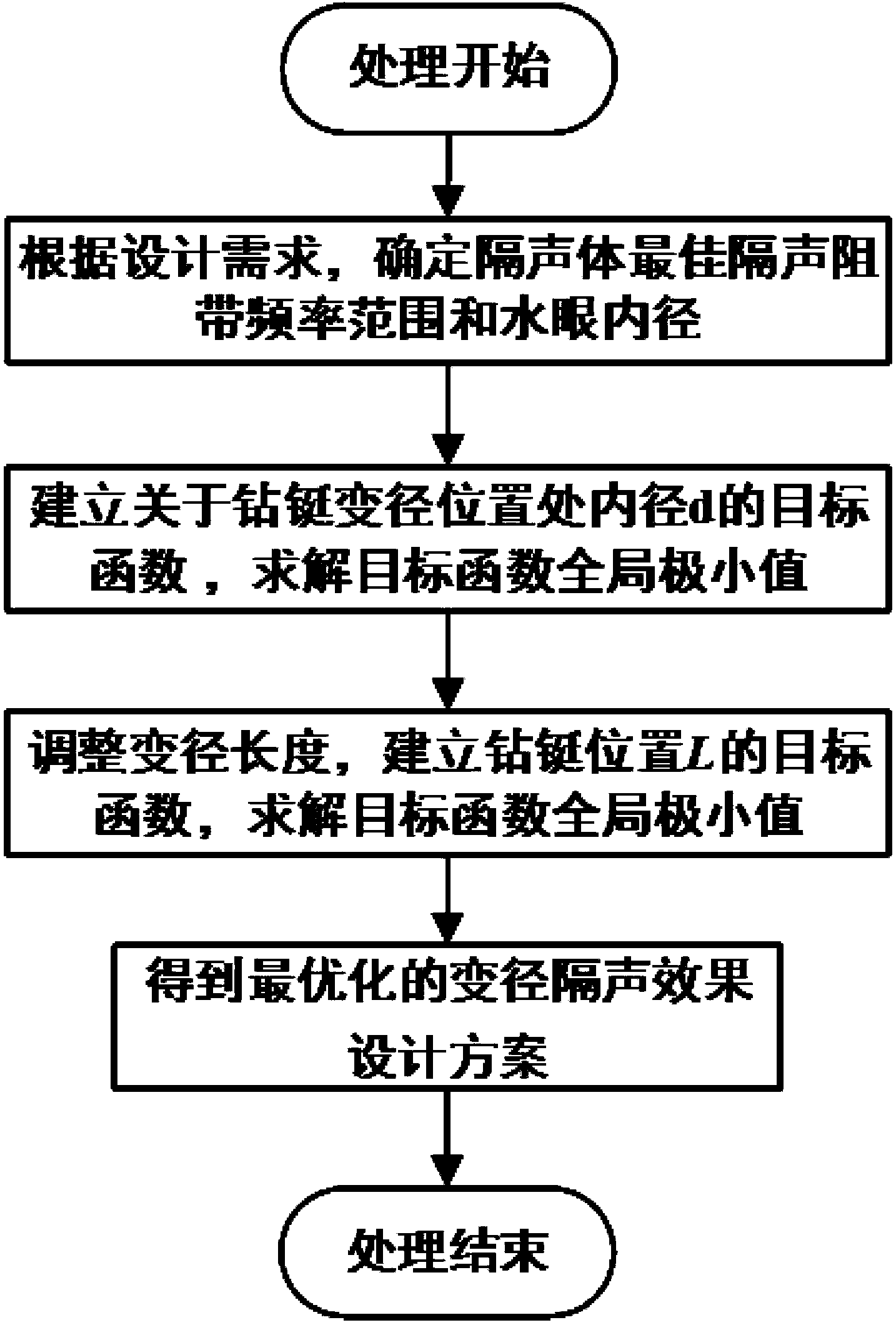

[0064] The optimal design method for the sound insulation of the sound system of the diameter-changing acoustic logging-while-drilling drill collar, such as figure 1 shown, including the following steps:

[0065] Step 1. According to the design requirements, determine the frequency range of the optimal sound insulation stop band of the sound insulation body and the inner diameter of the water hole

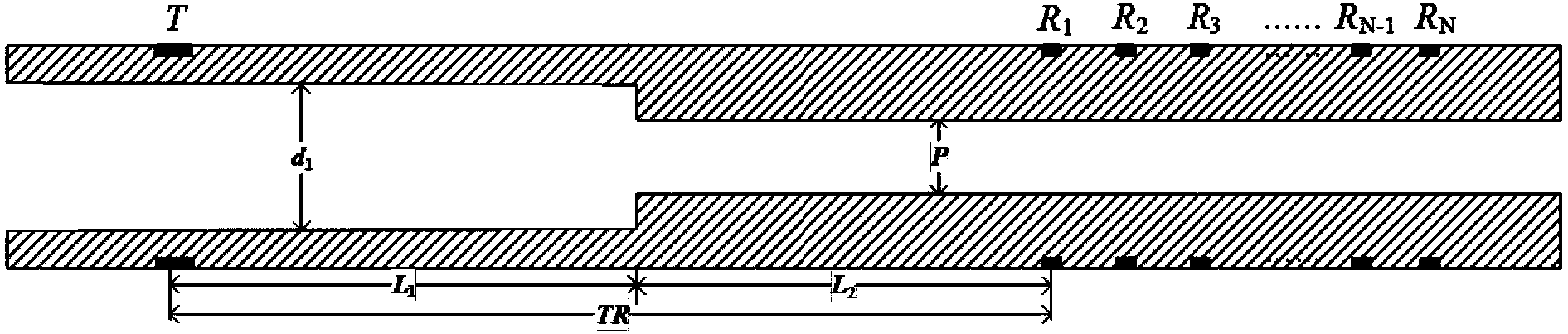

[0066] Figure 2a Transmitting sound source transducer T and receiving transducer R are shown 1 , R 2 , R 3 、...R N-1 , R N Schematic diagram of the sound system for a diameter change. The inner diameter of the drill collar from the transmitting sound source transducer T to the receiving transducer is d 1 and P, starting from the emitting sound source transducer T, the variable diameter lengths are L respectively 1 and L 2 , T in the figure is the transmitting sound source transducer, and the receiving transducer array is N, respectively R 1 , R 2 , R 3 、...R N-1 , R ...

Embodiment 2

[0080] The optimal design method for the sound insulation of the sound system of the reduced-diameter acoustic logging-while-drilling drill collar with secondary diameter reduction, such as figure 1 shown, including the following steps:

[0081] Step 1. According to the design requirements, determine the frequency range of the sound insulation body's optimal sound insulation stop band and the inner diameter of the water hole.

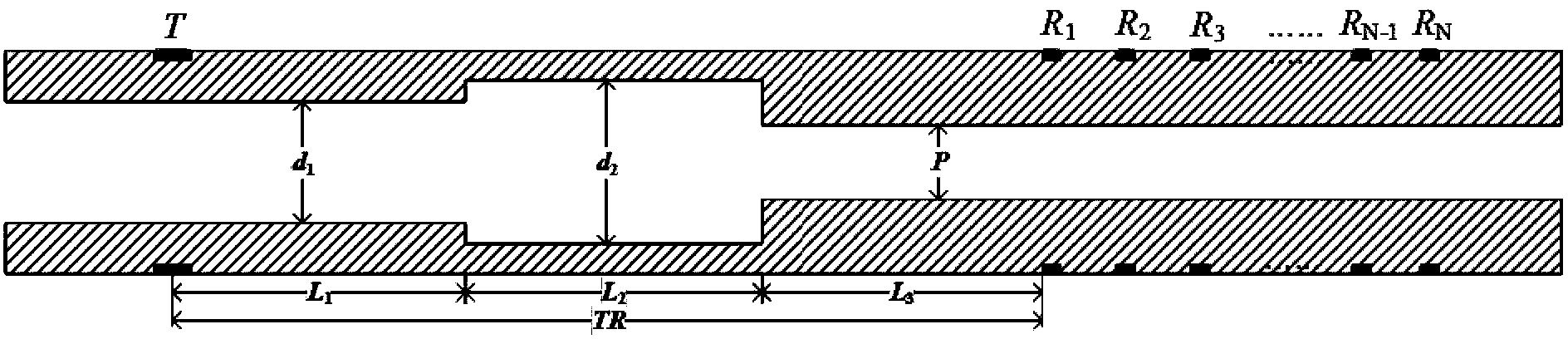

[0082] Figure 2b Shown is a schematic diagram of the acoustic system of the secondary diameter reduction between the transmitting sound source transducer T and the receiving transducer, and the inner diameters of the drill collars from the transmitting sound source transducer T to the receiving transducer array are respectively d 1 、d 2 and P, starting from the emitting sound source transducer T, the variable diameter lengths are L respectively 1 , L 2 and L 3 , T in the figure is the transmitting sound source transducer, and the receiving transdu...

Embodiment 3

[0096] The optimal design method for the sound insulation of the sound system of the variable-diameter sound system of the acoustic logging-while-drilling drill collar with three times of diameter reduction, such as figure 1 shown, including the following steps:

[0097] Step 1. According to the design requirements, determine the frequency range of the optimal sound insulation stop band of the sound insulation body, the wall thickness of the drill collar and the inner diameter of the water hole

[0098] Figure 2c Shown is a schematic diagram of the sound system of a diameter change between the transmitting sound source transducer T and the receiving transducer, and the inner diameters of the drill collars from the transmitting sound source transducer T to the receiving transducer are respectively d 1 、d 3 、d 2 and P, starting from the emitting sound source transducer T, the variable diameter lengths are L respectively 1 , L 2 , L 3 and L 4 , T in the figure is the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com