Moisture-proof corrosion-proof coaxial cable

A coaxial cable, anti-corrosion technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of operators' disgust, difficult control, and many quality problems, and achieve the solution of incompatibility problems, and the process is simple and convenient , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

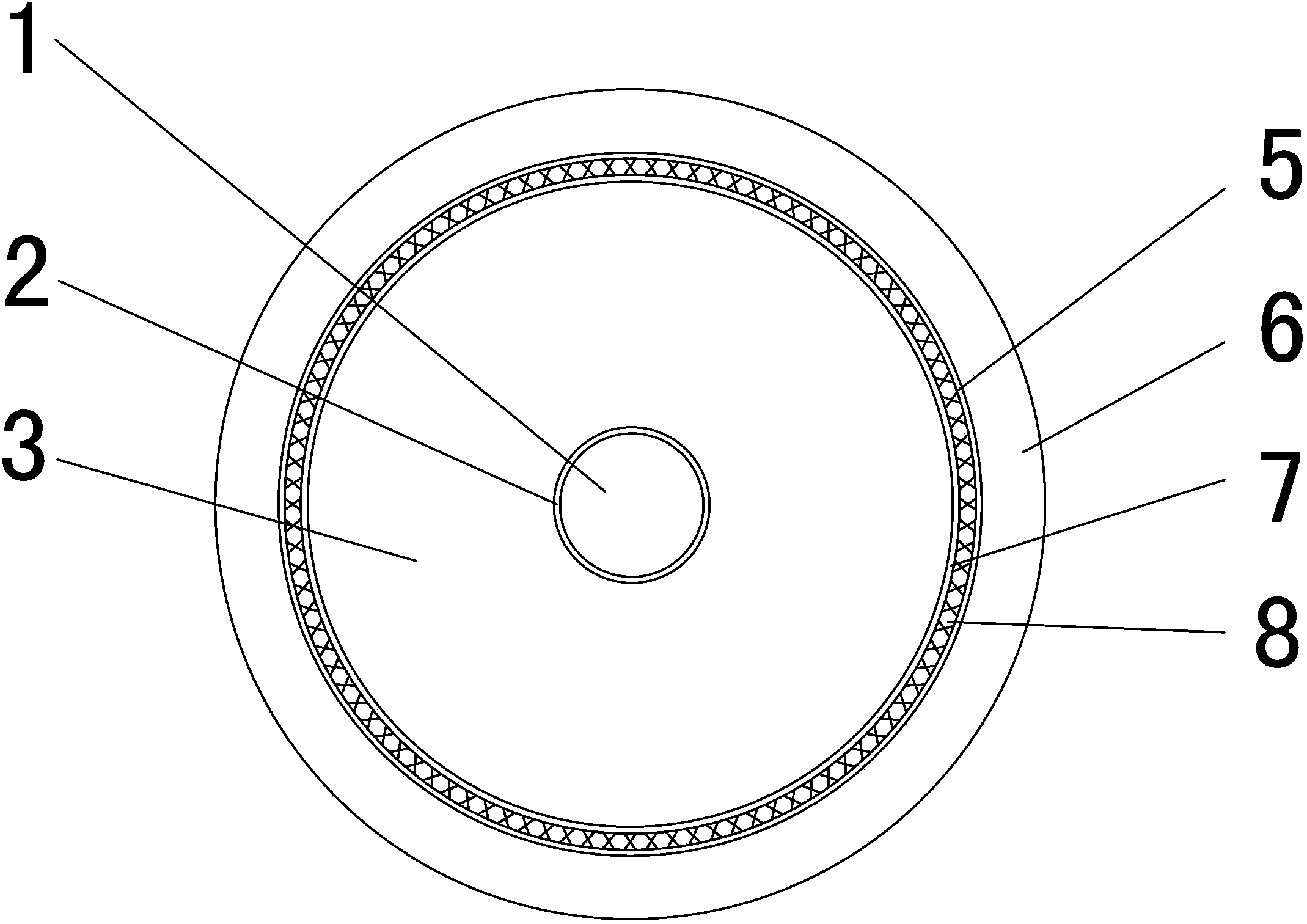

[0016] Refer to attached figure 1 , a moisture-proof and anti-corrosion coaxial cable, including an inner conductor 1, an insulating layer 3, an outer conductor and an outer sheath 6, an inner crust layer 2 is arranged between the inner conductor and the insulating layer, and the outer conductor is made of an aluminum foil layer 7 and braiding layer 8, a filling layer 5 is provided between the outer conductor and the outer sheath, and the inner conductor, inner crust layer, insulating layer, aluminum foil layer, braiding layer, filling layer and outer sheath are sequentially along the diameter Set from the inside out. The filling layer is a self-prepared mineral oil mixture. The mineral oil mixture is a semi-liquid mixture that can be filled by dropping or spraying before the extrusion head of the sheath production. The formula of the mineral oil mixture is: mineral oil A, mineral oil B, antioxidant, the weight ratio is (80-85): (14-19): (0.8-1.2); the mineral oil A is A hig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap