Method for reducing aluminium residual quantity in salted jellyfish

A technology of residues and jellyfish, applied in applications, food preparation, food science, etc., can solve problems such as harm to human health, aluminum toxicity, etc., and achieve the effects of promoting dissolution, reducing aluminum residues, and preventing swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

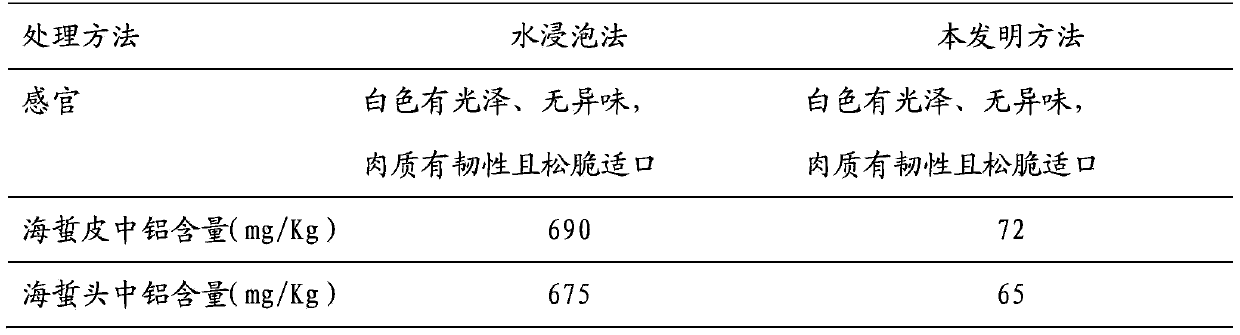

[0013] The technical scheme of the present invention is used to process the salted jellyfish peels purchased from the market with the traditional three-aluminum process, and finally perform sensory evaluation and determine the residual amount of aluminum therein.

[0014] A method for reducing residual aluminum in salted jellyfish. The steps include cleaning, soaking in a mixed solution of citric acid and calcium propionate and blanching in hot water. The specific steps are as follows:

[0015] 1) Cleaning: Wash the salted jellyfish skin with water to remove impurities, and cut into 1-5mm wide silk.

[0016] 2) Soaking in a mixed solution of citric acid and calcium propionate: put 500g of shredded salted jellyfish skin into a food-grade plastic bucket, add 1 liter of mixed solution of citric acid and calcium propionate to soak, the citric acid and calcium propionate The preparation method of the mixed solution is as follows: 1L of the mixed solution contains 10ml of food addit...

Embodiment 2

[0019] The technical scheme of the present invention is used to process the salted jellyfish heads purchased from the market and processed by the traditional three-aluminum process, and finally carry out sensory evaluation and measure the residual amount of aluminum therein.

[0020] A method for reducing residual aluminum in salted jellyfish. The steps include cleaning, soaking in a mixed solution of citric acid and calcium propionate and blanching in hot water. The specific steps are as follows:

[0021] 1) Cleaning: Take the salted jellyfish head and wash it with water to remove impurities.

[0022] 2) Soaking in the mixed solution of citric acid and calcium propionate: put 500g of salted jellyfish heads into a food-grade plastic bucket, add 3 liters of mixed solution of citric acid and calcium propionate to soak, the preparation of the mixed solution of citric acid and calcium propionate The method is to contain 20ml of food additive citric acid and 20g of food additive ca...

Embodiment 3

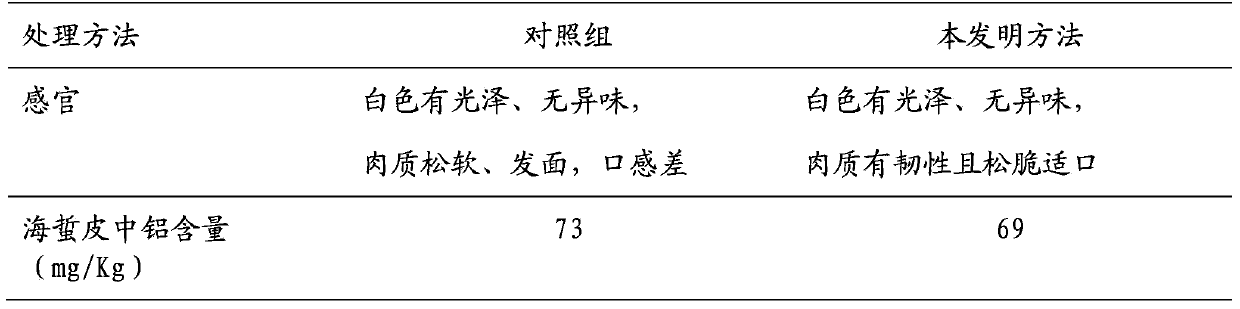

[0028] One of the key points of the present invention is that calcium propionate is added while soaking in citric acid. Since the salted jellyfish swells in the citric acid solution, the taste of the salted jellyfish is severely reduced, and the commercial value of the salted jellyfish is lost. , so adding calcium propionate at the same time can effectively prevent the swelling of salted jellyfish in the process of soaking in acid solution, and keep it crispy, palatable and tough, which will be verified by experiments below.

[0029] Process the salted jellyfish with the following different technical schemes to the salted jellyfish that is purchased from the market and processed with the traditional three alum process:

[0030] 1) Cleaning: Take the salted jellyfish skin and wash it with water to remove impurities.

[0031] 2) Soaking in the mixed solution of citric acid and calcium propionate: put 500g of salted jellyfish skin into a food-grade plastic bucket, add 3 liters of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com