Method for retaining freshness of single-frozen shelled shrimps by electrolyzed water

A technology for electrolyzed water and shrimps, applied in the fields of application, food preservation, food science, etc., can solve the problems of high manufacturing cost of strong acid electrolyzed water, unreported electrolyzed water, unstable effective chlorine, etc., to solve the safety of pathogenic microorganisms. Control problems, ensure quality and safety and consumers' health, and achieve good fresh-keeping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

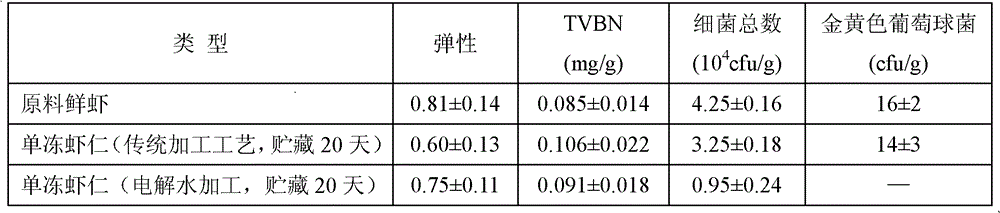

example 1

[0020] At room temperature, the concentration of 0.10% NaCl aqueous solution is prepared by electrolytic water preparation equipment (such as Yantai Fangxin electrolytic water equipment) to produce weakly acidic electrolysis with pH 5.0-6.8, redox potential 850-1100mV, and available chlorine content 20-60ppm Water, the prepared weakly electrolyzed water can be frozen to produce active electrolyzed ice with a pH of 5.0-6.8; fresh shrimps are purchased, and the temperature is lowered and cleaned with 4°C weakly acidic electrolyzed water (pH 5.0, redox potential 1100mV, available chlorine content 60ppm). Then, in a clean fish plate (basket), a layer of electrolytic ice (pH6.0) and a layer of fresh shrimp are kept fresh and stored in a pre-cooler (0-5°C); After shelling, use weakly acidic electrolyzed water (pH 5.0, oxidation-reduction potential 1100mV, available chlorine content 60ppm) to rinse 3 times at 4°C; clean water (in line with drinking water standards) to rinse 2 times; p...

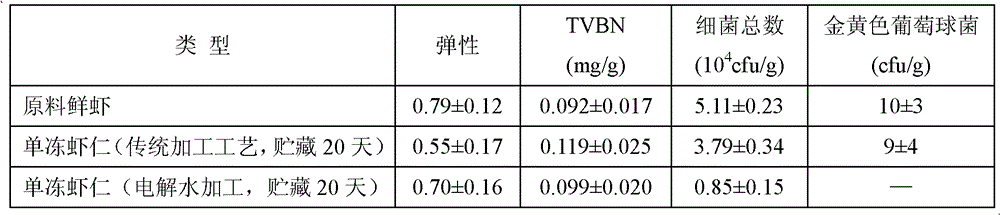

Embodiment 2

[0024] At room temperature, the concentration of 0.15% NaCl aqueous solution is prepared by electrolytic water preparation equipment (such as Yantai Fangxin electrolytic water equipment) to produce weakly acidic electrolysis with pH 5.0-6.8, oxidation-reduction potential 850-1100mV, and available chlorine content 20-60ppm Water, the prepared weakly electrolyzed water can be frozen to produce active electrolyzed ice with a pH of 5.0 to 6.8; fresh shrimps are purchased, and the temperature is lowered and cleaned with 5°C weakly acidic electrolyzed water (pH 5.0, redox potential 900mV, available chlorine content 50ppm). Then put a layer of electrolytic ice (pH 6.8) and a layer of fresh shrimp in a clean fish plate (basket) for fresh-keeping treatment and store them in a pre-cooler at 5°C; Rinse twice with weakly acidic electrolyzed water (pH 5.0, redox potential 900mV, available chlorine content 50ppm) at 4°C; rinse with clean water (in line with drinking water standards) 3 times;...

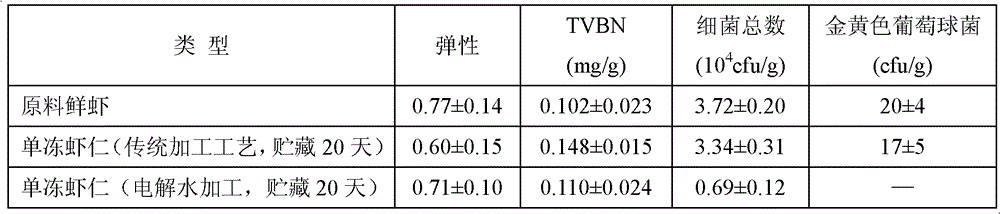

Embodiment 3

[0028] At room temperature, the concentration of 0.20% NaCl aqueous solution is prepared by electrolytic water preparation equipment (such as Yantai Fangxin electrolytic water equipment) to produce weakly acidic electrolysis with pH 5.0-6.8, redox potential 850-1100mV, and available chlorine content 20-60ppm Water, the prepared weakly electrolyzed water can be frozen to produce active electrolyzed ice with a pH of 5.0-6.8; fresh shrimps are purchased, and the temperature is lowered and cleaned with weakly acidic electrolyzed water (pH 5.2, redox potential 1000mV, available chlorine content 55ppm) at 0°C. Then put a layer of electrolytic ice (pH 6.5) and a layer of fresh shrimp in a clean fish tray (basket) for fresh-keeping treatment and store them in a pre-cooler at 5°C; Rinse 4 times with weakly acidic electrolyzed water (pH 5.2, redox potential 1000mV, available chlorine content 55ppm) at 0°C; rinse with clean water (in line with drinking water standards) once; place the dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com