Complex mineral active bath agent

A technology of compound minerals and active state, applied in the direction of inorganic active ingredients, active ingredients of iodine compounds, active ingredients of phosphorus compounds, etc., can solve the problems of affecting the quality of fresh milk and high recurrence rate, and achieve a wide range of bacteriostasis, low recurrence rate, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

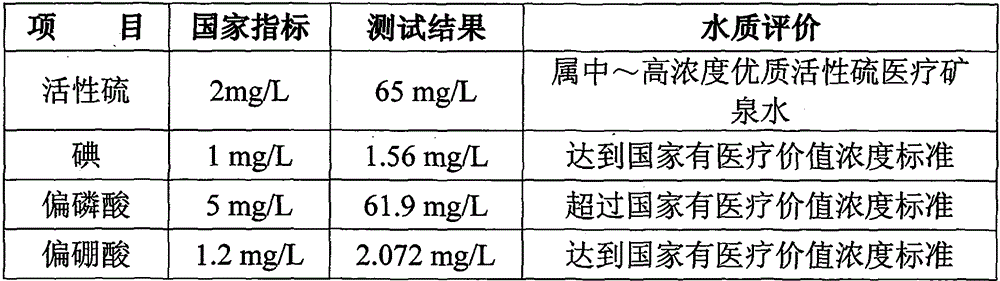

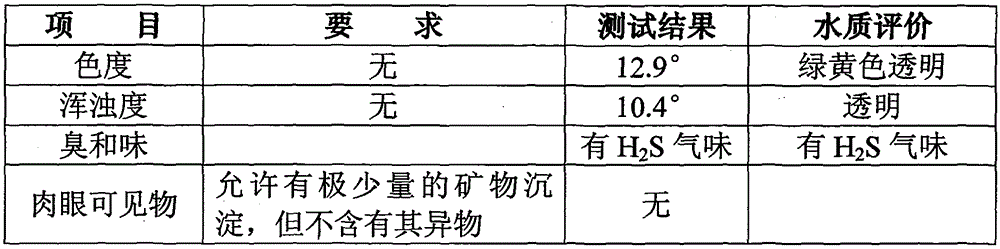

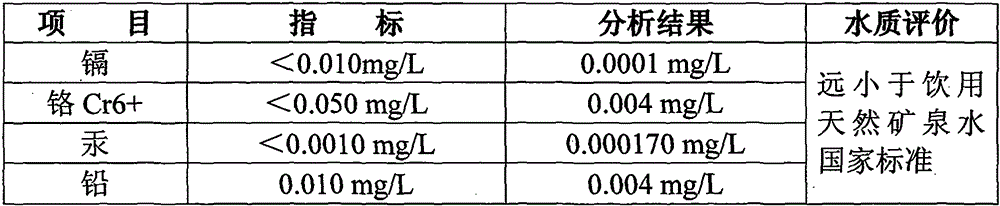

Embodiment 1

[0011] The compound mineral active state bath agent is composed of aphanitic volcanic tuff, powdery massive sulfur, sodium hydrogen phosphate, iodine, sodium bicarbonate, and water. 2 parts, 20 parts of powdery massive sulfur, 2 parts of sodium hydrogen phosphate, put into a sealed melting tank, fill with nitrogen, discharge the air, heat to 1500 degrees, while heating and stirring, from room temperature to 1500 degrees at least 3 hours, then stir while cooling down to room temperature for at least 3 hours to obtain a gray granular high-temperature melting semi-product; (2) put the gray granular high-temperature melting semi-product into a catalytic tank, add 1 part of iodine, Fill with nitrogen, discharge air, heat to 200°C, and catalyze for more than 4 hours; (3) Put the catalyzed product into a free tank, add 2 parts of sodium bicarbonate and 1900 parts of water, leave it for 5 hours, and pack it into a bag. That is the finished product.

[0012] The product of this embodi...

Embodiment 2

[0022] The production method of composite mineral active state bath agent: (1) 100 parts of aphanitic volcanic tuff, 40 parts of powdery massive sulfur, and 6 parts of sodium hydrogen phosphate are put into a sealed melting tank by weight and filled with nitrogen, Exhaust the air, heat to 1800°C, heat and stir, and rise from room temperature to 1800°C for at least 3 hours, then cool down while stirring, and drop to room temperature for at least 3 hours to obtain a gray granular high-temperature fused semi-product; ( 2) Put the gray granular high-temperature fused semi-product into the catalytic tank, add 1.6 parts of iodine, fill with nitrogen, discharge the air, heat to 230°C, and catalyze for more than 4 hours; (3) put the catalyzed product into Put it into the free tank, add 12 parts of sodium bicarbonate and 1900 parts of water, leave it for 5 hours and pack it into a bag, which is the finished product.

Embodiment 3

[0024] The production method of composite mineral active state bath agent: (1) 70 parts of aphanitic volcanic tuff, 30 parts of powdery massive sulfur, and 4 parts of sodium hydrogen phosphate are put into a sealed melting tank by weight and filled with nitrogen, Exhaust the air, heat to 1650 degrees, heat and stir, rise from room temperature to 1650 degrees for at least 3 hours, then cool down while stirring, and drop to room temperature for at least 3 hours to obtain a gray granular high-temperature fused semi-product; ( 2) Put the gray granular high-temperature fused semi-product into the catalytic tank, add 1.3 parts of iodine, fill with nitrogen, discharge the air, heat to 210°C, and catalyze for more than 4 hours; (3) put the catalyzed product Put it into the free tank, add 7 parts of sodium bicarbonate and 1900 parts of water, leave it for 5 hours and pack it into a bag, which is the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com