Novel nozzle for high-pressure washer, and high-pressure spray gun

A technology of a high-pressure cleaner and a high-pressure spray gun, which is applied in the direction of cleaning methods and appliances, spray devices, spray devices, etc., can solve the problems of unfavorable long-term use, pressure loss, and large pressure loss, and achieve good cleaning effect, long service life, The effect of small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

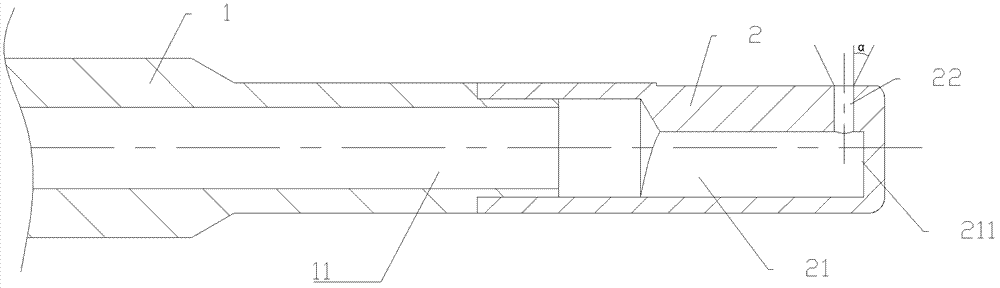

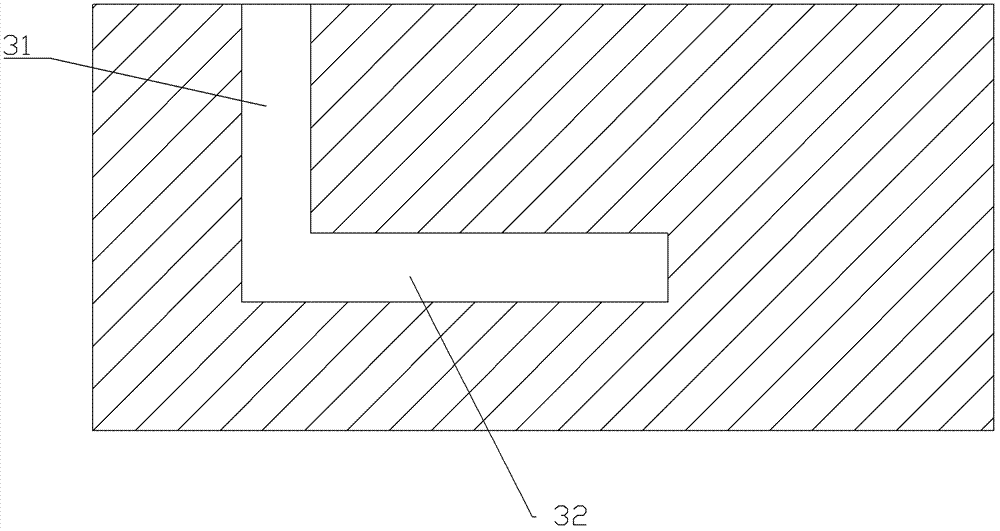

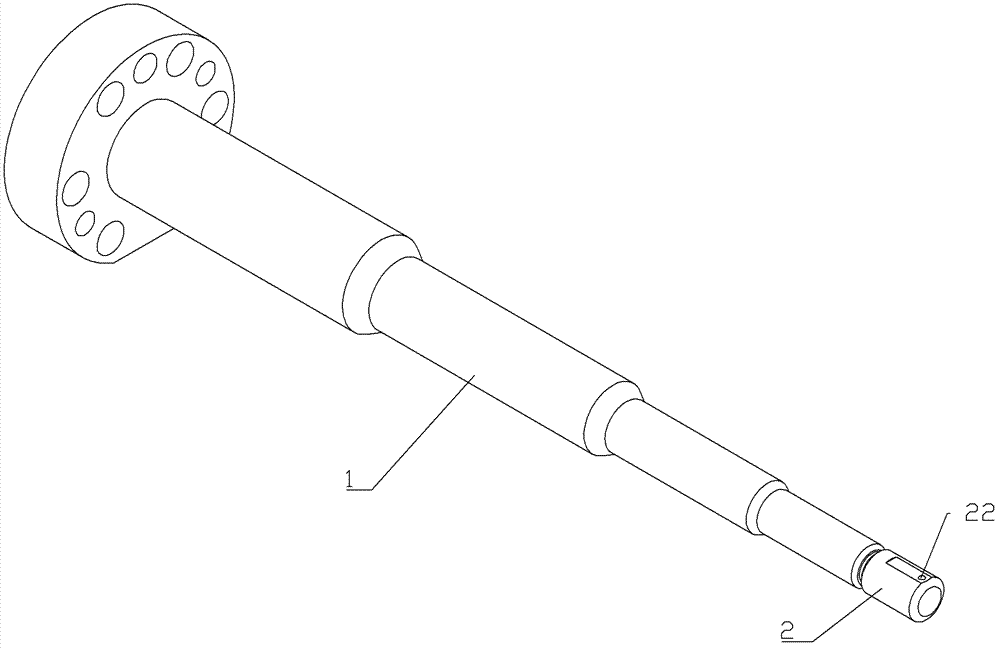

[0038] Such as image 3 , Figure 4 As shown, the high-pressure spray gun includes a spray gun body 1 with a guide hole 11 . The diversion hole 11 has a diversion hole inlet 12 and a diversion hole outlet 13 . A nozzle head main body 2 is installed at the end of the spray gun body 1 . The nozzle head main body 2 has spray holes 22 and guide grooves 23 . The diversion groove 23 is arc-shaped. One end of the diversion groove 23 is a diversion groove inlet 231 and the other end is a diversion groove outlet 232 . The diversion groove inlet 231 communicates with the diversion groove outlet 232 . The diversion groove 23 smoothly extends from the diversion groove inlet 231 with a larger diameter to the diversion groove outlet 232 with a smaller diameter, that is, the inner wall of the diversion groove 23 will not produce protrusions, and will not be affected by the protrusions during the high-pressure water flow process. blocking. The diameter of the diversion groove inlet 231 i...

Embodiment 2

[0041] Such as Figure 5As shown, the high-pressure spray gun includes a spray gun body 1 with a guide hole 11 . The diversion hole 11 has a diversion hole inlet 12 and a diversion hole outlet 13 . A nozzle head main body 2 is installed at the end of the spray gun body 1 . The nozzle head main body 2 has spray holes 22 and guide grooves 23 . The guide groove 23 is arc-shaped. One end of the diversion groove 23 is a diversion groove inlet 231 , and the other end is a diversion groove outlet 232 , and the diversion groove inlet 231 communicates with the diversion groove outlet 232 . The diversion groove 23 smoothly extends from the diversion groove inlet 231 with a larger diameter to the diversion groove outlet 232 with a smaller diameter, that is, the inner wall of the diversion groove 23 will not produce protrusions, and will not be affected by the protrusions during the high-pressure water flow process. blocking. Both the inlet 231 of the diversion groove and the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com