Method for separation and purification of 1-octylene from hydrocarbon (oxygen) mixture

A technology of mixing materials and mixtures, applied in the direction of distillation purification/separation, organic chemistry, etc., can solve the problems of complex process steps and difficulty in reaching the polymerization level, etc., and achieve the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

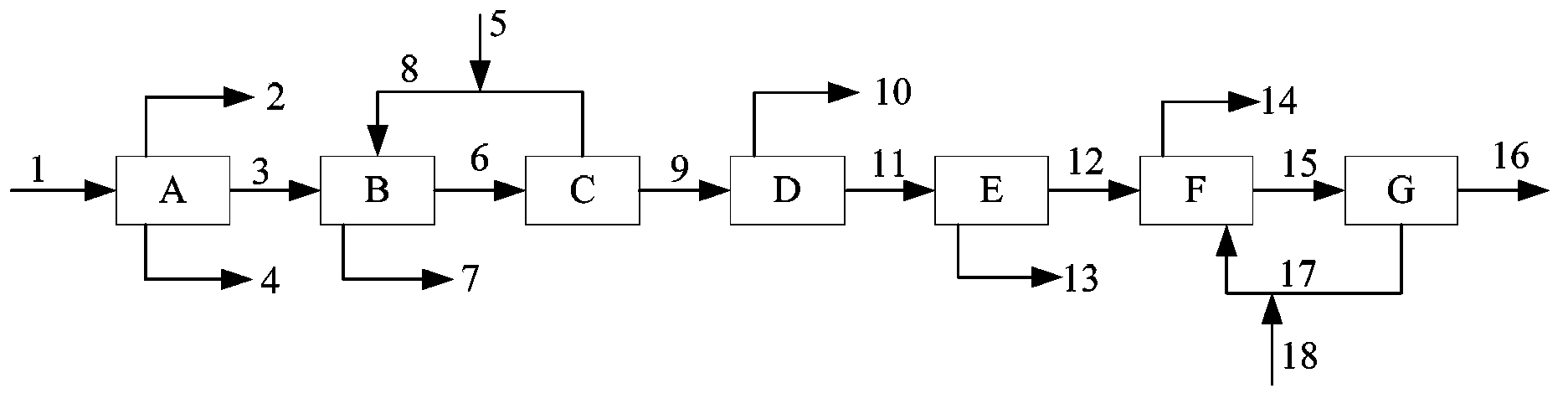

[0038] Hydrocarbon (oxygen) mixture raw material stream 1 is pre-separated through pre-separation unit A double tower to obtain C 8 Distillate stream 3 (composition see Table 1), C 8 - Light ends stream 2, C 8 +Heavy ends stream 4 where C 8 Distillate stream 3 enters the azeotropic distillation column B, the number of theoretical plates is 20, the feeding position is 10 plates from the top, the reflux ratio is 2.6, the temperature at the top of the tower is controlled at 73-75°C, and the temperature at the bottom of the tower is 121-123 ℃, the azeotropic agent and C 8 The hydrocarbon stream 6 enters the entrainer recovery tower C, the number of theoretical plates is 25, the reflux ratio is 1, the feeding position is 11 from the top, the temperature at the top of the tower is controlled at 61-64°C, and the temperature at the bottom of the tower is 113-117°C , the tower top extracts the enriched entrainer stream 8, and this stream returns to the phase separator circulation at...

Embodiment 2

[0044] Hydrocarbon (oxygen) mixture raw material stream 1 obtains C after double tower pre-separation 8 Distillate stream 3 (composition see Table 2), C 8 Distillate stream 3 enters the azeotropic distillation column B, the number of theoretical plates is 10, the feeding position is 5 plates from the top, the reflux ratio is 4, the temperature at the top of the tower is controlled at 73-76°C, and the temperature at the bottom of the tower is 125-127°C ℃, C extracted from the top of the tower 8 Hydrocarbons and entrainer stream 6 enter entrainer recovery tower C, the number of theoretical plates is 10, the reflux ratio is 10, the feed position is 5 plates from the top, the temperature at the top of the tower is controlled to be 60-62°C, and the bottom of the tower is 114 ~116°C, the azeotrope-enriched stream 8 is extracted from the top of the tower, and the stream is returned to the phase separator at the top of the azeotropic distillation column for circulation, and the oxyge...

Embodiment 3

[0049] Hydrocarbon (oxygen) mixture raw material flow 1 obtains C after being separated by a single dividing wall tower 8 Stream 3 (see Table 3 for composition), C 8 Distillate stream 3 enters the azeotropic distillation column B, the number of theoretical plates is 50, the feeding position is 25 plates from the top, the reflux ratio is 2.6, the temperature at the top of the tower is controlled at 73-75°C, and the temperature at the bottom of the tower is 108-111°C ℃, the rich oxide stream 7 is extracted from the bottom of the tower, and C is extracted from the top of the tower 8 The hydrocarbon and entrainer stream 6 enters the entrainer recovery tower C, the number of theoretical plates is 50, the reflux ratio is 0.5, the feeding position is 25 plates from the top, the temperature at the top of the tower is controlled to be 58-59°C, and the bottom of the tower is 113 ~115°C, the azeotrope-enriched stream 8 is extracted from the top of the tower, and the stream is returned t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com