A kind of composite asphalt modifier and its preparation method and application

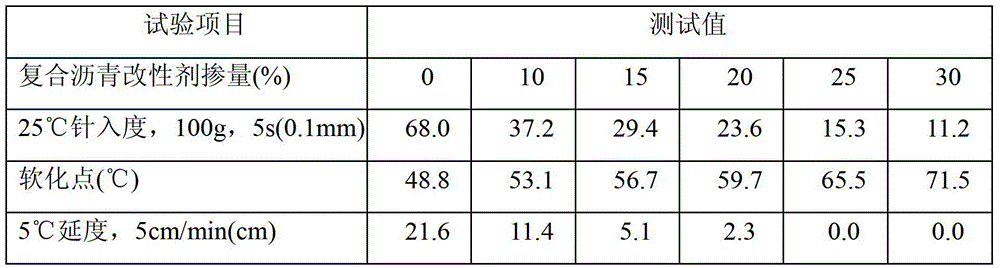

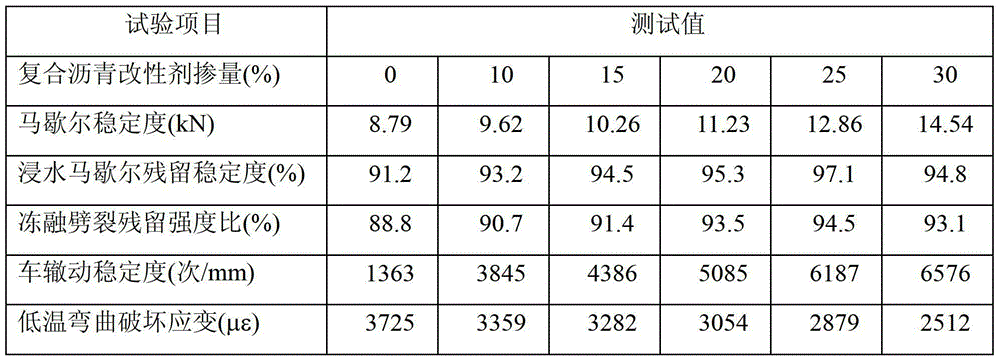

A composite asphalt and modifier technology, which is applied in the field of asphalt modifiers, can solve the problems of difficult compatibility of base asphalt, large investment in modification equipment, complicated modification process, etc., and achieve an increase in softening point, decrease in penetration, The obvious effect of economic advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In the preparation of the asphalt mixture of the present invention, there is no need to specifically limit the amount of aggregate and mineral powder added.

[0031] All the stirring in the present invention is a conventional stirring method in the art, without special limitation.

Embodiment 1

[0033] A composite asphalt modifier, prepared by the following steps:

[0034] Take 25% of rock pitch, 40% of No. 10 petroleum pitch, and 35% of coal tar pitch; grind the rock pitch to 400 meshes, put No. 10 petroleum pitch into the reactor and heat to 300°C, slowly add coal pitch, Then add rock asphalt, develop for 1 hour, and start the mixer throughout the whole process; after the development, release the processed asphalt to cool to room temperature, and then grind it to 100 mesh to obtain a composite asphalt modifier.

Embodiment 2

[0036] A composite asphalt modifier, prepared by the following steps:

[0037] Take 20% rock asphalt, 40% No. 10 petroleum pitch, and 40% coal tar pitch; grind the rock pitch to 700 mesh, put No. 10 petroleum pitch into the reactor and heat to 260°C, slowly add coal tar pitch, Then add rock asphalt, develop for 2 hours, and start the mixer throughout the whole process; after the development, release the processed asphalt to cool to room temperature, and then grind it to 200 mesh to obtain a composite asphalt modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com