Adhesive composition, adhesive sheet, and optical member

A composition and adhesive technology, which is applied in the direction of optical components, conductive adhesives, adhesive types, etc., can solve the problems of specific metal usage concerns and restrictions, and achieve excellent adhesive properties and excellent pot life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

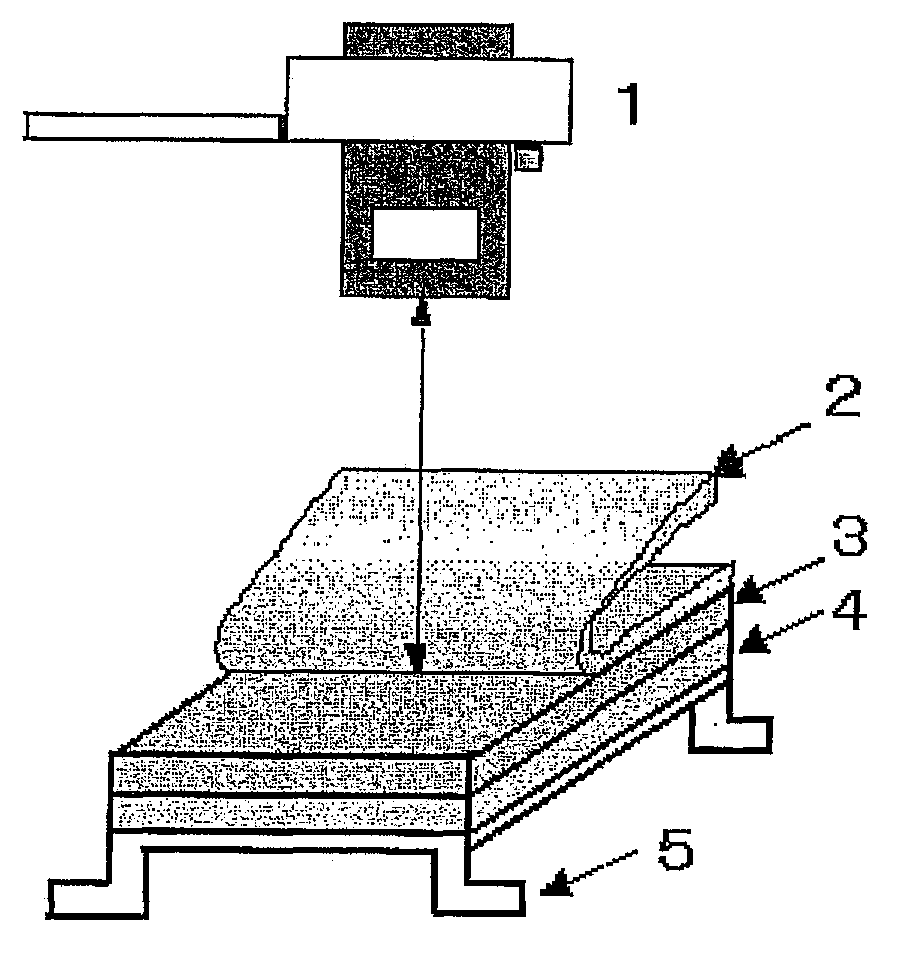

Image

Examples

Embodiment 1

[0155] [Preparation of binder solution]

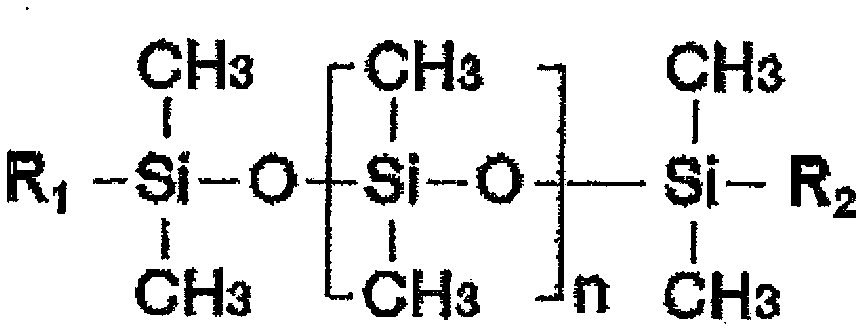

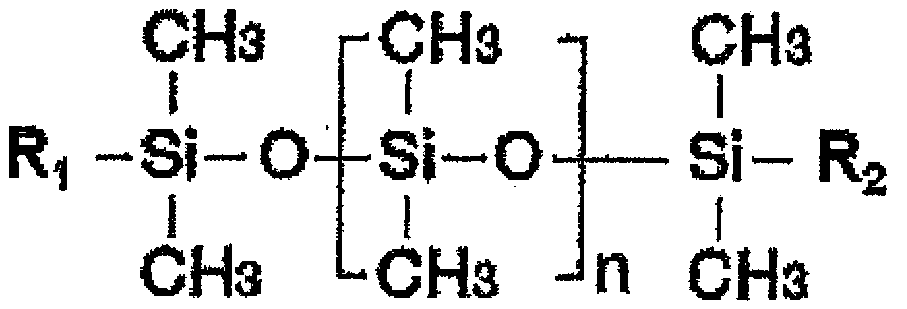

[0156] The above-mentioned (meth)acryl-based polymer solution (40% by weight) was diluted to 20% by weight with ethyl acetate, and 500 parts by weight of the solution (100 parts by weight of solid content) was added to have an oxyalkylene group in the side chain. Organopolysiloxane (trade name: KF-353, manufactured by Shin-Etsu Silicone Co., Ltd., HLB value 10) diluted with ethyl acetate to 10% solution 2 parts by weight (solid content 0.2 parts by weight), will be used as an anti- Lithium bis(trifluoromethanesulfonyl)imide (LiN(CF 3 SO 2 ) 2 : LiTFSI, produced by Tokyo Chemical Industry Co., Ltd.), 5 parts by weight of a solution diluted to 1% with ethyl acetate (0.05 parts by weight of solid content), and the isocyanurate body of hexamethylene diisocyanate as a crosslinking agent (Japan Coronate HX manufactured by Polyurethane Industry Co., Ltd.) 1.5 parts by weight (solid content: 1.5 parts by weight), tris(acetylacetonate)iron (...

Embodiment 2~11、 comparative example 1~5

[0160]As shown in Table 1, a (meth)acryloyl-based polymer (may be simply referred to as a polymer) was prepared in the same manner as in Example 1 by changing the types, compounding amounts, and the like of the raw material monomers. It should be noted that additives not listed in the table were prepared in the same compounding quantities as in Example 1. Moreover, using the said polymer, it carried out similarly to Example 1, and obtained the adhesive composition and adhesive sheet (surface protection film).

Embodiment 12

[0162] In Example 12, 0.2 parts by weight of a polyether-type surfactant not containing organopolysiloxane (trade name 17R-4, manufactured by ADEKA Co., Ltd., number average molecular weight 2500, PO content 60% by weight) was used instead of In Example 1, except that 0.2 parts by weight of the above-mentioned organopolysiloxane (trade name: KF-353, manufactured by Shin-Etsu Silicone Co., Ltd., HLB value: 10) was used, it was carried out in the same manner as in Example 1, etc., to obtain Adhesive composition and adhesive sheet (surface protection film).

[0163] [evaluate]

[0164] The (meth)acryl-based polymer (polymer), the adhesive composition (solution), and the adhesive sheet obtained in Examples and Comparative Examples were evaluated by the following measurement methods or evaluation methods. In addition, as evaluation results, the evaluation of the physical properties of the polymer is shown in Table 1, the evaluation of the adhesive composition is shown in Table 2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com