Thermal treatment method for preventing stainless steel from being sensitized in water chamber of high-pressure heater

A technology of high-pressure heaters and heat treatment methods, which is applied in the field of heat treatment to achieve the effects of prolonging equipment life, ensuring performance, and ensuring system safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

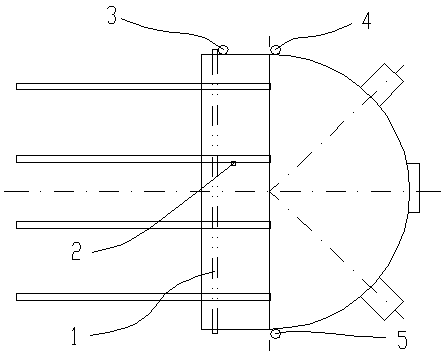

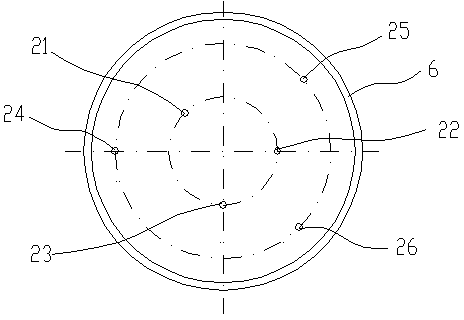

[0017] The technical solutions of the present invention will be further described in detail below through embodiments and in conjunction with the accompanying drawings.

[0018] This embodiment is a heat treatment method for preventing stainless steel sensitization in the water chamber of the high-pressure heater, and the welding between the thick tube plate 6 and the spherical head of the water chamber of the high-pressure heater is taken as the processing object. The heat treatment process is carried out in a heat treatment furnace. Before sending it into the heat treatment furnace, in the area of the thick tube sheet 6 and the U-shaped tube and the tube hole area, use the ordinary aluminum silicate ceramic fiber blanket as the thermal insulation blanket to wrap and reinforce the area, and use the thermal insulation blanket to seal the circular seam welds. All heat-affected zones are wrapped and sent to the heat treatment furnace. The heat treatment temperature is 600°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com