Steel used for voltage stabilizer of pressurized water reactor power station and manufacture method of steel

A technology for pressurized water reactor nuclear power plants and manufacturing methods, which is applied in the field of steel for pressurized water reactor nuclear power plant regulators and its manufacture, and can solve the problem of the decrease in the yield strength and tensile strength of steel plates and the inability to meet the requirements for the construction of the main equipment of the pressurized water reactor nuclear island. Tensile strength can not meet the index requirements and other problems, to achieve the effect of excellent strength index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

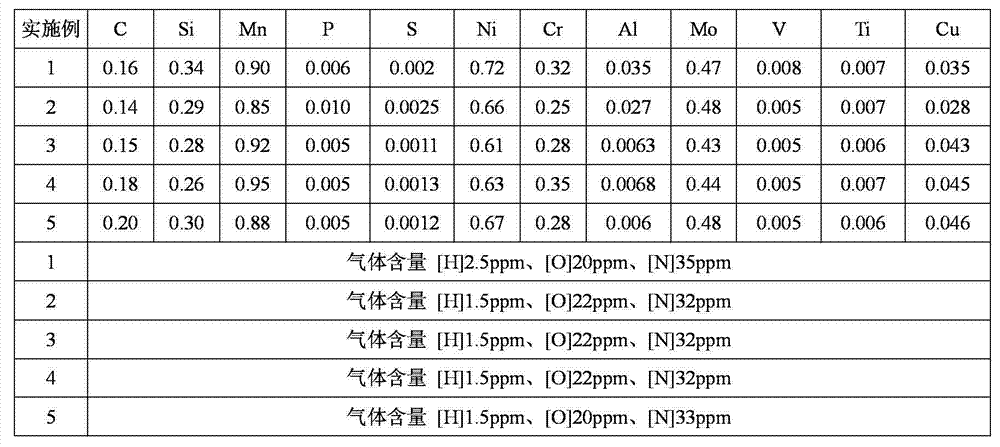

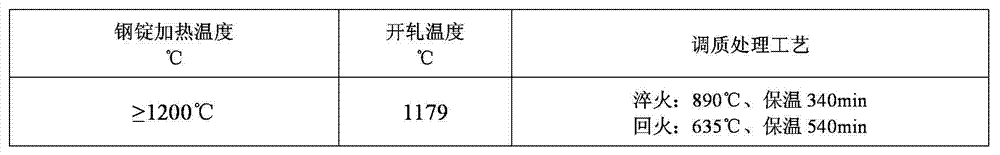

[0039] The steel used for the pressurized water reactor nuclear power plant voltage stabilizer in this embodiment is smelted in a converter, refined outside the furnace, and vacuum-treated, and cast into a continuous casting slab with a thickness of 300mm. The rolling and heat treatment process is shown in Table 2, and the mechanical properties are shown in Table 3.

[0040] Table 2 Rolling and heat treatment process of steel in Example 1 of the present invention

[0041]

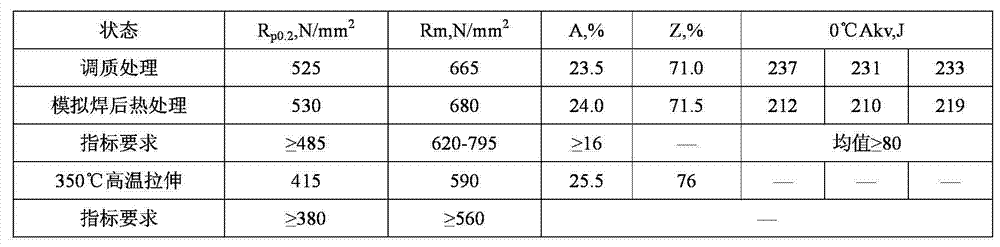

[0042] Table 3 The results of the mechanical properties of steel in Example 1 of the present invention

[0043]

[0044] It can be seen from Table 3 that after quenching and tempering treatment and simulated post-weld heat treatment, the performance indicators of the 20mm steel plate of the present invention fully meet the requirements. Steel requirements for compressors.

Embodiment 2

[0046] The steel used for the pressurized water reactor nuclear power plant voltage stabilizer in this embodiment, the molten steel is smelted in a converter, refined outside the furnace (LF, VD), cast into a continuous casting slab with a thickness of 300mm, and the finished steel plate specification is 40mm (see the table for its chemical composition 1). The rolling and heat treatment process is shown in Table 4, and the mechanical properties are shown in Table 5.

[0047] Table 4 Rolling and heat treatment process of steel in Example 2 of the present invention

[0048]

[0049] Table 5 The results of the mechanical properties of steel in Example 2 of the present invention

[0050]

[0051] It can be seen from Table 5 that after quenching and tempering treatment and simulated post-weld heat treatment, the performance indicators of the 40mm steel plate of the present invention fully meet the requirements, and the tensile strength of the steel plate is close to the midd...

Embodiment 3

[0053] The steel used for the pressurized water reactor nuclear power plant voltage stabilizer in this embodiment, the molten steel is smelted by the converter, refined outside the furnace (LF, VD), cast into a continuous casting slab with a thickness of 300mm, and the finished steel plate specification is 60mm (the chemical composition is shown in the table 1). The rolling and heat treatment process is shown in Table 6, and the mechanical properties are shown in Table 7.

[0054] Table 6 Rolling and heat treatment process of steel in Example 3 of the present invention

[0055]

[0056] Table 7 The results of the mechanical properties of steel in Example 3 of the present invention

[0057]

[0058] It can be seen from Table 7 that after quenching and tempering treatment and simulated post-weld heat treatment, the performance indicators of the 60mm steel plate of the present invention fully meet the requirements, and there is a certain margin, which fully meets the requi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com