Sanitary product surface treatment method

A bathroom product and surface treatment technology, applied in the field of nickel plating and chrome plating on the surface of bathroom products, can solve the problem that the performance of bathroom products is difficult to meet the requirements of CASS test, and achieve the effect of increasing thickness, improving coating quality and ensuring purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

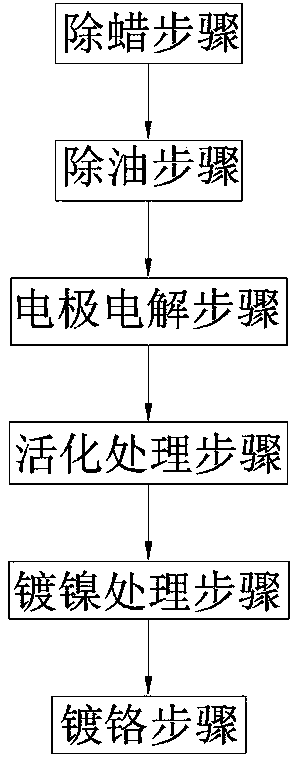

[0021] Such as figure 1 As shown, this embodiment discloses a surface treatment method for sanitary products. This method is used for surface nickel and chrome plating of bathroom products. The method includes the following steps:

[0022] (1) First put the sanitary products in dewaxing water with a concentration of 2-4%, keep the temperature at 65-75°C for 6-10 minutes; then add an ultrasonic device to perform ultrasonic de-waxing in the temperature range of 60-65°C Wax for 2 to 3 minutes, and then enter the next step after washing with water.

[0023] (2) Perform multiple ultrasonic degreasing and chemical degreasing, including the first, second, third ultrasonic degreasing and one chemical degreasing steps. The first ultrasonic degreasing step: carried out in a solution with a concentration of 40-50g / L added with degreasing powder, at a temperature of 60-65°C, and for 2-3 minutes; chemical degreasing step: after adding degreasing powder The concentration of the powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com